| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Disassemble Waltham 16s Jeweled mtr bbl

Disassemble Waltham 16s Jeweled mtr bbl

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Disassemble Waltham 16s Jeweled mtr bbl

Disassemble Waltham 16s Jeweled mtr bblGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

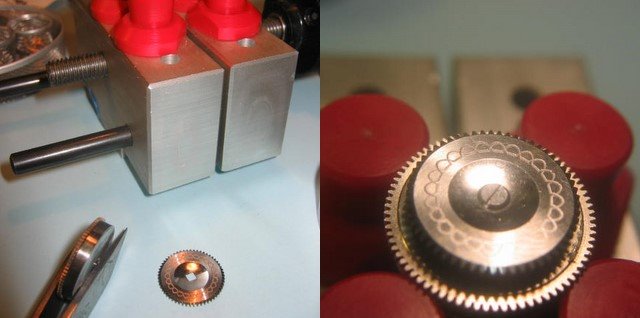

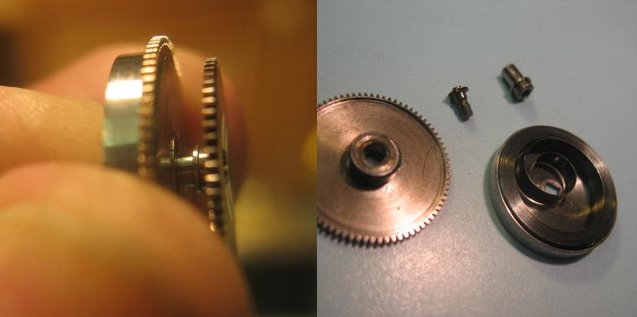

During one of my diatribes about jeweled motor barrels, I promised to expain disassembly of the 16s Waltham model 1908 motor barrel. The barrel assembly pictured is from a 21 Jewel 16s Waltham 645, a true purpose built RR grade. Waltham added to a perfect 17 jewel movement a jeweled motor barrel to minimize isochronism and then capped the escape jewels to make it a "true 21". HOWEVER disassembling the motor barrel MUST BE DONE CAREFULLY! to prevent catastrophic damage to the jewels and the components of the motor barrel assembly. My method is too easy for words, but here it is, firstly, you need three things; 1. The Motor Barrel Assembly; 2. The original click wheel and mounting screw that attaches it to the motor barrel arbor; 3. A nice device (movement holder) with "soft" jaws that can clamp the barrel firmly at 3 or 4 places around the circumferunce. To start; A. Screw the click wheel to the barrel assembly. B. Clamp the motor barrel part of the assembly FIRMLY in the soft jawed holder.  | ||

|

| IHC Life Member |

C. Pinch the click wheel with your fingers and; 1. Unscrew it (counter-clockwise). After less than 1 turn, it will free-wheel because the bottom screw-threaded piece of the motor arbor has released itself from the square hole in the barrel. 2. Take the barrel assembly out of the soft clamp, and hold it so you can press the bottom screw-threaded piece back into its square hole and unscrew the top end of the arbor that is still attached to the click wheel. 3. Remove the click wheel and its screw, and put the arbor top nut and bottom screw thread end parts aside for cleaning. Then; D. Carefully rotate the motor drive end away from the motor barrel so the toothed arbor on the drive wheel disengages from the main spring. You had disassembled the motor! NOTE the hollow center motor drive stem of the barrel assembly has JEWELS pressed into both ends of it so that it is free to power the watch by unwinding the main spring from the rest of the assembly that is secured by the click wheel and pivot holes in the watch plates. This is a very clever design, and those of you who are "gear heads" will also note the winding is done through the jewels as well!  | |||

|

David, Thank you for your many "how to" articles. As a newbe, I for one appreciate them. Especially the Waltham and Illinois ones. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Disassemble Waltham 16s Jeweled mtr bbl

Disassemble Waltham 16s Jeweled mtr bbl

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Disassemble Waltham 16s Jeweled mtr bbl

Disassemble Waltham 16s Jeweled mtr bbl©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide