| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Recommended technique for securing hairspring stud to bridge

Recommended technique for securing hairspring stud to bridge

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Recommended technique for securing hairspring stud to bridge

Recommended technique for securing hairspring stud to bridgeGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

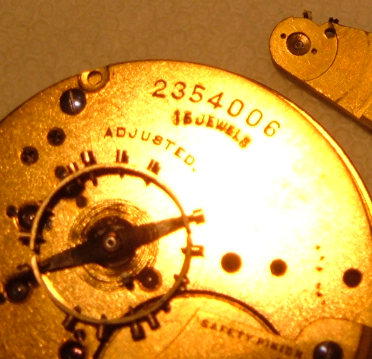

Would you describe the technique, you use, to replace the hairspring stud in the balance bridge? In reassembling a watch, I place the balance into it's pivot hole, set the roller jewel in beat with the pallet fork, and then place the balance bridge on top. Then I try to push the hairspring stud, from underneath the balance bridge, to the stud's hole. I take a curved tweezer to push it up through, from the underside. This technique has worked well for me on 16-sized Elgins, but I have found it to be much more difficult on a 14-sized Elgin. In the process, I bent the hairspring at the stud, placing the hairspring coils out of true (it is possible that the hairspring was already bent there--I bought the watch on eBay for some practice). I've got bigger problems now--the hairspring broke in two, at the point of the breguet's bend. Can these troubles be easily avoided with a different technique or tool? I can't imagine how I could accomplish this task on a smaller watch, like a lady's wrist watch. (Much to small to put anything under the balance bridge to lift the stud). What do you do on a watch like this? | |||

|

With the exception of a few Walthams that have a triangular stud. I always attach the stud to the balance cock while it is off of the movement. Here's my process, I'm sure there are other ways... With the stud screw loosened, I place the cock upside down and stick it to my bench with a small piece of Rodico. I will oil the balance cock hole jewel now. I then lower the balance, upside down, on to the balance cock, setting it so that the stud falls into the hole. If you are able to set the pivot into the hole jewel, the hairspring will usually find the gap in the regulator pins on its own. Tighten the hairspring stud screw and your done. The entire cock and balance assembly can then be removed from the Rodico and placed onto the watch. It takes a little practice but once you have done a few, it is easy Mike Miller | ||||

|

| IHC Life Member |

Willy, With the exception of some Walthams, I always attach the balance assembly to the balance cock first. Then dangle the balance by the hairspring during installation or gently use tweezers to hold the balance and cock together and insert them into postion. I find it easier to use the dangle method. Especially when you are trying to place the roller jewel into the pallet fork. This is probably the most critical maneuver when reassembling the movement. As you gain experience, you will develop a "feel" for when something is likely to become damaged if you continue. NEVER force anything into postion. This is where most people make costly mistakes. John D. Duvall Vice President, Education | |||

|

Thanks for the suggestions--I will try it that way next time. It seems like it would be difficult to install the balance into the pivot and pallet fork, when it is bouncing around. I will try to grip, both the balance and the bridge in the tweezers at the same time. | ||||

|

It might seem hard, but if done gingerly, it usually falls into place and just starts ticking away. A little trick is to have the fork banked towards the center wheel, dangle the balance while holding the bridge in the tweezers. rotate the balance and bridge with a counterclockwise twist into position and set it in place. Mike Miller | ||||

|

| IHC Life Member |

Willy, Just remember not to force anything into position. I can't stress that enough. When using the tweezers, never grip anything tighter than what is necessary to gently hold it. It's also a good idea to work closely to the bench when installing the balance & cock. If the cock should fall away from the movement when using one of the old wooden movement holders, you can easily damage the hairspring. John D. Duvall Vice President, Education | |||

|

Thanks for the tips! That is how I broke this last hairspring--when it fell to the bench from the movement holder. Thanks a lot! I will try again with another watch! | ||||

|

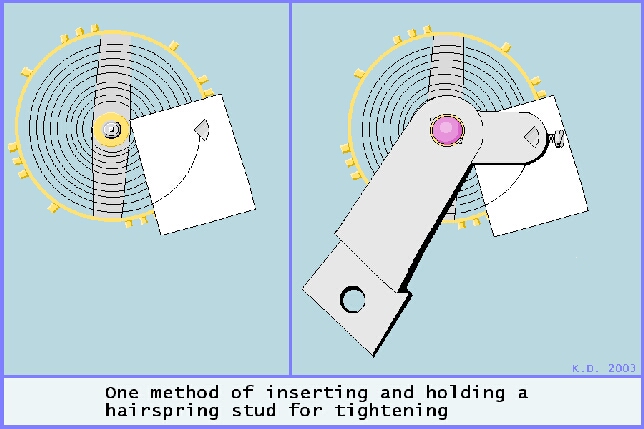

Some of the methods above are I suppose preferable and maybe easier but I throw this in to show there are more ways than one to "skin a cat". After much frustration and fumbling when I first tried replacing studs this method evolved after many attempts. I use a small thin card or piece of stiff paper. Inserting it under the stud between stud and next coil. (See illustration below) Holding this in my right hand I then place the balance cock over and onto the stud checking to see that the hairspring is between the reguator pins. When this is accomplished and the stud is seated properly I transfer everthing to my left hand with thumb on top of balance cock and fingers beneath balance wheel. Now the stud is held in securely and my right hand is free to tighten the stud screw. As previously stated you have to be careful when working with balance assemblies. Take care not to put too much pressure on the pivot or jewel. This method somewhat shields the hairspring but still be careful with the screwdriver. Remember you want to merely lead the stud to it`s position. Don`t force anthing. I agree 100% with John. If things aren`t going well, walk away from it for a while. There have been many times when I couldn`t seem to work things out, only to come back the next day to find it was a piece of cake. I don`t know if others are like this or not but I have to get in the repair mood. Some days I know not to even try. If I do I know I will have problems. Guess you just have to have your mind totally into it. I also "dangle" the balance into position. If the roller isn`t in proper position I raise the balance cock with a toothpick then raise and turn bal. wheel. Kenny  | ||||

|

That is a good way kenny.I find the studs that are just wedged into the balance cock into a v shaped area and then tighten down the screw are the hardest for me to assemble. I have also tried putting the balance wheel back onto the plate with the lower pivot in the jewel and then attach the balance cock, screw it down till snug, with top pivot in jewel also.With the movement in a holder andd them manipulate the stud into position and tighten it down.I guess what ever works best for the individual is the best way to go. | ||||

|

In my work I usually put the balance wheel/hairspring assembly onto the upside-down balance cock, insert the stud and tighten the screw if the watch has a hole through the cock for the stud. Trying to put the stud in after assembly has risks, as Willy found. HOWEVER, when the stud can be swung into place after assembly, as it is meant to be with Waltham's triangular stud or with a collar-button stud (found on some Hampden, Hamilton, Illinois and many high-grade Swiss watches), then I assemble the watch first and then affix the stud. | ||||

|

Thanks again, for everyone's responses to my question. You all gave me some good ideas. Thanks Kenny for your illustration! That looks safer than trying to lift it with tweezers or a screwdriver. Mike, I have another question about your use of Rodico. You state that you turn the balance cock upside down, attaching it to your bench with the Rodico. Why do you need the Rodico? Why don't you just place the balance cock upside down on your bench? Do you push the balance wheel into the Rodico (after you place it in the balance cock pivot) to aid you in putting the entire balance assembly into the watch, after you stud it? Or, do you remove the assembly from the Rodico before placing it into the watch? | ||||

|

Sorry for the delay, As a clarification, the Rodico is used only as a stucky base to keep the balance bridge in place on the bench. Another way of doing this would be to use a taper pin through the bridge's screw hole into a bench block. Mike Miller | ||||

|

There is a fixture (tool) that can be used to hold the balance cock/balance that prevents accidential damage. I do not remember the name, perhaps another Chapter 185 member might know the correct name for the fixture.  | ||||

|

Balance tack. Sam Williamson NAWCC 154312 IHC Charter Member 14 Member Chapters 96 and 185 | ||||

|

I'm finding it extremely difficult to get the hairspring between the two regulator guide pins on this Waltham Appleton Tracy. Is there a trick I don't know about yet? Dave Turner  | ||||

|

Well, I re-read all of this thread and heeded the instruction. Walk away from it, let it rest and go back later. I'm learning the number 1 rule, (for me). Patience, and persistence. Got her running. Dave Turner | ||||

|

| IHC Life Member |

I use Rodico on some assemblies but usually just use a toothpick stuck upright in a bench anvil and then slide the bridge over it. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Recommended technique for securing hairspring stud to bridge

Recommended technique for securing hairspring stud to bridge

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Recommended technique for securing hairspring stud to bridge

Recommended technique for securing hairspring stud to bridge©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide