| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Putting Timing Weight in Perspective

Putting Timing Weight in Perspective

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Putting Timing Weight in Perspective

Putting Timing Weight in PerspectiveGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

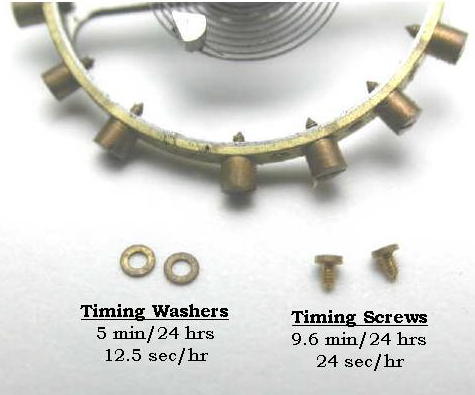

I thought this picture might add a little perspective of how weight affects timing. The photo depicts an average 16s Elgin balance wheel. Compare the size of the screws located on the balance with the screws and washers shown beneath. As you can see, it doesn't take much weight to make a big difference. As Steve Maddox mentioned in another post, the regulator's full range is only good for about 6 minutes. The small timing washers almost account for that! Lets say you work long and hard to get the watch running to within 10 seconds per day, dial up. Did you poise the balance after all of the timing screw and washer additions, subtractions, or undercuttings? If you didn't, the watch will not maintain the 10 seconds per day, in positions, you fought so hard to achieve. I don't want to dishearten anyone but getting a watch to keep reasonable time can be hard, painstaking work. John D. Duvall Vice President, Education  | ||

|

| Watch Repair Expert |

John, That's a great image above, and I greatly admire your photographic skills, but for those who might not fully appreciate the size of the items pictured, how much trouble would it be to show them beside a common item, such as a staple or a straight pin? I don't have the necessary photographic equipment to produce fine images like that, but I do have a precision analytical balance, and if I get a chance later today, I'll try to weigh some timing washers and report the results. I might also weigh some other common items, and report those results as well for comparative purposes. On a similar note, I recall a discussion a few years ago on the "green board" where I noted that it's possible to arrange 10 typical jewel screws in an area the size of an ordinary tomato seed. A number of people expressed doubt at that, and I didn't have the necessary photographic equipment to prove it, but I know for a fact that it can be done. Again, that would make an interesting image. As always, thanks for all your great work! ================ Steve Maddox Past President, Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

I like looking through my tupperware of misc. hardware and finding those really small screws. You know those that would get lost under your fingernail. I take them to class with me, my students just cant get enough of those really small things. I'll take in one watch screw and a cap screw from a EMD train engine and really blow their minds. I was called a true "Gear Head" by one of my students the other day. We were working on a GM Electromotive Diesel geartrain and using a overhead hoist to lift 100 lb gears into place. How is that for two extremes. Watch gears to 100 lb engine gears. Aaron | ||||

|

Aaron, At one time North Carolina issued a Watchmakers License.I was the only one I know who had a Watchmakers License and a Plumbers Union Card at the same time. J Smith Old Geezer #99 | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Putting Timing Weight in Perspective

Putting Timing Weight in Perspective

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Putting Timing Weight in Perspective

Putting Timing Weight in Perspective©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide