| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  what kind of escapement is this?

what kind of escapement is this?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  what kind of escapement is this?

what kind of escapement is this?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

hi everybody, i bought this old watch off of Jon Hart because i thought it looked like an interesting watch. Boy was i right! checked the balance, yep, broken staff. pulled the balance out looked at the escape wheel and saw the pallet fork was missing. then realized there isn't even a place to mount a pallet fork, what???? so now i am really having fun, seriously. took a real good look at the balance staff and figured out the escape wheel and balance are the escapement. no pallet fork! too cool!! what the heck is this called? and can it be repaired? i think i'm in love Todd  | |||

|

| IHC Member 1555 |

A Swiss cylinder escapement Todd where the escape wheel engages directly into the balance. No pallet fork needed. Cheers. | |||

|

thanks Bila, now on to the big question, is this fixable? i can't even find a name on the watch. | ||||

|

| IHC Member 1555 |

Definitely fixable, damaged cylinders are replaceable, albeit different technique and tools compared to normal American watch. Hardest tasks are the staff replacement and then ensuring you get the watch into beat. Most people do not like working on these as you will need more patience to learn the correct ways. You will probably get told that these are not great timekeepers but I have seen them regularly keep time within a minute or so over a week. | |||

|

| IHC Life Member |

Todd, This design was popular among the Swiss in the 1870's for reasons known to no one but them! The un-repairable nature of this design certainly helped the USA RR watch specs along to EXCLUDE Swiss-made watches from certification. As Bila explained, "Cylinder" (cases marked 'cyl[i]ndre') escapement movements are not popular to repair because there are many steps to a successful "fix". For a beginner watch repair person I reckon the odds of success are ZERO. Save it for a paperweight and go on with the easier to deal with stuff. | |||

|

Todd, Glad the watch and movements made it up North. I believe I put a couple of extra movements in there for you to "tinker" with. Especially, for learning the find art of "tinkering" with the hairspring (removal/installation - w/o damaging the collet or coils), removing the roller table, and balance staff itself. The best way to learn is on those free movements. Good luck | ||||

|

hi guys, David, i am going to take your word for it that this is beyond me for now. but it is something to shoot for. Jon, please do not in any way feel that i am unhappy with this purchase. this watch fascinates me and is part of my education. not to mention you threw in two free movements for me to play with. i have taken the free betsy ross you sent me apart and reassembled it twice just for practice. i have the roller table and pallet fork soaking in alcohol right now so i can remove her jewels and then practice shellacking them back in. just received my combination tool and alcohol lamp and fresh shellac and can't wait to practice this. if i found the broken balance pivot inside the cylindre watch, could i stick it back on to the staff with my arc welder? thanks guys i'm having a blast todd | ||||

|

Excellent / i am just glad we have found someone who loves to tinker... | ||||

|

| IHC Life Member |

SAME HERE! | |||

|

| IHC Member 1851 |

The S.la rose co. (now gone ) sold roughed in pivot plugs for repair . I may have a bag of asstd. I'll let you know if I find them. | |||

|

| IHC Member 1851 |

What I have are pivot caps, these likely wont help you.  | |||

|

i don't know Paul, if you look at the pic at the top of this post they kinda look right. David would know. meanwhile, i am going to measure the diameter of the base of my broken one. i'll be right back! so excited!!! todd | ||||

|

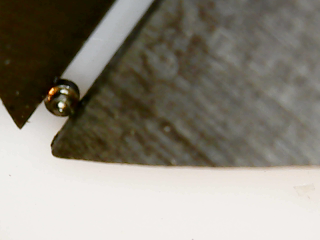

hi Paul. so, i found i could not measure the diameter of the broken balance pinion while still mounted in the staff. so i made a tool. i would like to introduce the "canadian made swiss cylinder escapement broken pinion remover tool" a rather specialized tool, but when you need it you will be happy you have it! made it from the finest sewing needle my wife had.  | ||||

|

i got so excited i couldn't find my balance tack, so i threw that together too. i reached inside the cylinder with my fancy new tool and pushed the broken pinion out.  | ||||

|

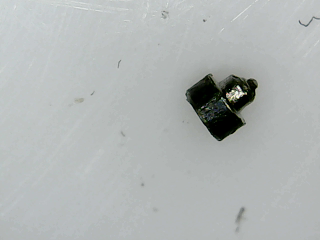

worked like a charm! here is the broken pinion!  | ||||

|

and no damage to the pinion mount that i can see. i haven't measured the broken pinion yet. need a break. but feeling pretty pleased right now. thanks everybody, back soon todd  | ||||

|

hi Paul, took some work, but got it into my caliper. the base is .80 mm  | ||||

|

Todd, Have a tube marked pivot caps. These are roughly .85 mm in thickness If you think they will work can send you a couple Does the staff (pivot cap as a possible fix) just pop into the little basket looking "thing"? | ||||

|

hi Jon, keeping in mind that i trust Davids assessment that the odds of me getting this movement working are zero, i would love to try. so yes, i would love to have them, but i think the bases are too long. (see mine) but i would file them down and love them and do my best to make it work. still, i think Pauls' look more like what i need i sent you an email, re: the second hand. let me know. i will never use it. todd | ||||

|

Todd, You know - I think you will get that movement running... Don't doubt yourself, that's what haters are for! | ||||

|

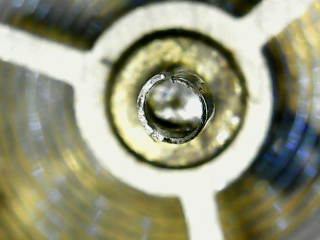

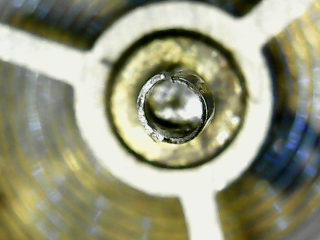

the staff looks like it was staked into the "basket looking thing" there are 3 notches along the rim of the "basket" you can see in this pic where a staking punch has hit it  | ||||

|

i have never in my life doubted myself Jon. but i accept that the odds of me fixing this are very low. nevertheless i must try.!! if i had accepted the odds of the prettiest girl in school saying yes to me, i never would have tried. but i did. and we have been married for 33 years. and i love her more today than i did yesterday. i can't help myself, i love a challenge! always have. i want to try to make this run. todd P.S. what did you think of my homemade tool? | ||||

|

| IHC Member 1357 |

Todd,I just want to commend you on your exsuberance.I look forward to your posts and your continuing adventures. Regards Roger | |||

|

| IHC Life Member |

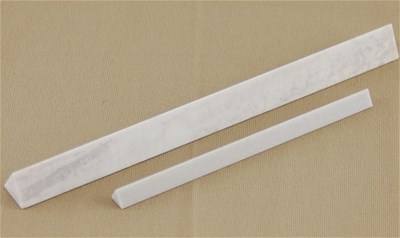

So do I. Get a small Arkansas stone to work the pivots. http://www.sharpeningsupplies....PrP84B3BtRoCO87w_wcB  | |||

|

Todd my motto is "If they can do it so can I". | ||||

|

| IHC Member 1851 |

I'll try to measure mine soon and let you know. Make way for a good fit, no distortion. The cylinder should be hard tempered, making it fragile. | |||

|

| IHC Member 1851 |

The largest in my asst .76 | |||

|

hi Paul. i believe Jon is sending me a couple of .85mm but i would like a couple of your .76mm as well. i want to cover my bases. how much would you want for them? Todd | ||||

|

thank you to everyone for your support and encouragement. tinkering with these watches would quickly become boring without you. i would get stuck and frustrated. yet, when i ask for help you are there to offer me support and advice. that is what makes this fun for me. i truly appreciate you all. thank you todd | ||||

|

| IHC Life Member |

Todd, I like your homemade canadian made swiss cylinder escapement broken pinion remover tool. It looks just like the Presto model 10 precision pointy-poker. :0) William | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide