| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Help needed with Hampden center wheel

Help needed with Hampden center wheel

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Help needed with Hampden center wheel

Help needed with Hampden center wheelGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I`ve located the problem with an 18s Hampden, 17j, model 3 that I have. Two of the teeth on the center wheel are broken off. I have a spare center wheel complete but it was from a 15j model so the lower pivot will not fit the jeweled hole. What I need to know is can the center staffs be exchanged and if so how? I believe the staffs are referred to as "threaded" and I can unscrew the safety pinion but does the staff simply screw in to the wheel? Thought it best to get some input before I maybe start down the wrong road. Any advice is greatly appreciated.Thanks! | |||

|

| IHC Life Member |

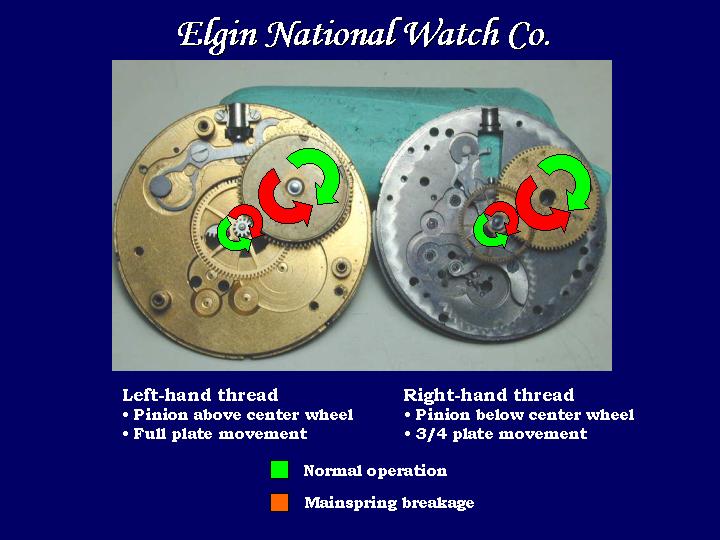

Kenny, This is somewhat unusual for a movement protected by a safety pinion to have broken center wheel teeth if it was a result of mainspring breakage. Was the mainspring broken when you took it apart? If so, also examine the mainspring barrel teeth closely for any damage. I'm not familiar with Hampden's but I know that if you unscrew the safety pinion on an Elgin, the arbor can be pulled out from the center wheel. When I get home from work tonight, I'll check my parts manual and see if Hampden's are of a similar design. If your watch is a full plate design (pinion above center wheel), the safety pinion should have left-hand threads. Be careful not to break any pinion leaves when trying to unscrew it. Please see the attached chart.  | |||

|

John, This is a recent ebay purchase so I don`t have any history on it. The mainspring is fine as are all the teeth on the barrel. It was wound as tight as it could be when I received it. It will run until the broken teeth make their circuit. The safety pinion has left-hand threads and I have no trouble removing it. Ihe staff is firmly attached to the wheel even after removing the safety pinion however and I hesitate to try to turn or force anything until I know how it is fitted. This watch is full plate and the wheel looks very similar to the Elgin. The Hampden material list has two different type center staffs listed for 18s. One is listed as "spring" and the other "threaded". I see no evidence of any "spring" so presume this is the threaded type. The back side of the wheel/staff has a three pronged center that looks to be part of the staff. The three little triangular points fit into three triangular cutouts in the brass wheel. The front part under the safety pinion is round and not flush with the wheel. It is a hair or so higher than the wheel plane but doesn`t look rivetted. Kenny | ||||

|

| IHC Life Member |

Kenny, Sorry but I couldn't find any info at home on Hampden's. Maybe Ed, Rich or one of the other pro's have worked on one of these before. | |||

|

John, Thanks for your effort anyway. Kenny | ||||

|

| IHC Member 155 Bulova Watchmaker |

Kenny, Can you post some pictures of the two components. I suspect the wheel is just staked on. As large a picture as possible. I don't have a referance book to consult on this one Rich Kuhn IHC Member 155 | |||

|

| IHC President Life Member |

Kenny and Everyone, I am often extremely impressed at the lengths our members will go to in order to help each other. As always JohnD's illustrative information is amazing. Last night I brought Kenny's situation to the attention of both Rich Kuhn (see his correct prediction above) and Ed Ueberall who both unselfishly provided their professional expertise. The following response came in a few minutes ago from Ed Ueberall. WHAT A GREAT GUY!!! THANKS A MILLION ED!!! Lindell Here is Ed's very generous response in it's entirety... Lindell, Sorry for the delay, but I had to disassemble a movement and then unstake the center wheel to get the attached scan. As you can see on the scan, the center shaft is staked to the center wheel gear. The three "indentations" are the staking marks, and the wheel is very tight to the arbor. To unstake the wheel drive the arbor out from the side with the indentations. You don't even need to remove the safety pinion gear to do this, but I would recommend it. The new center shaft can then be inserted and restaked to the gear wheel. However, I think it would be a lot easier to chuck up the new center wheel assy into a lathe and reduce the pivots to the jewel diameter of the original movement. This would avoid centering problems when restaking and/or having the new stake either working loose in use or breaking part of the assembly. The attached scan is way too large for the board, please feel free to resize and post it, along with any of the above comments that you feel would be helpful. Best regards, Ed | |||

|

Ed, First off, thank you for going to all that trouble for me. I appreciate it though I didn`t intend for you to put in all that extra time and effort! Your scan and info are right on the money. I have four options (1) Unstake and replace the staff (2) Reduce the pivot size on a lathe (3) Cut the broken teeth out, solder in a plug and file new teeth (4) Secure a wheel with the proper pivot size. The 2nd option is out since I don`t have a lathe, number 3 is way too tedious, etc., if all else fails I have option 4. I will likely opt for unstaking, exchanging and restaking the center staffs. If I am careful and select the correct punches and anvil/stump holes this probably will work fine. Rich, Thanks, I tried to scan the wheels but my scanner does a very poor job unless the object is flat. Lindell, I appreciate your effort also! I too am impressed and very grateful to the thoughtfulness and unselfish sharing of info by folks like John, Rich and Ed. This shared knowledge is not a one way street and doesn`t have to dead-end with the receipient. Hopefully we all can help as we have been helped! And the beat goes on... Kenny | ||||

|

I removed the staff from the broken wheel with no problem but on closer inspection of the donor wheel I find that it most certainly wouldn`t fit correctly on the original staff anyway. Though there are three indentations, the individual prongs are rectangular on the 15j wheel whereas the original 17j has small triangles. Don`t know why I didn`t spot this in the beginning? Will have to wait till I locate a correct wheel or get the pivot re-turned to proper size. Thanks again to all. Seems like there is always one more "pot to wash"! And if there are any "easy fixes" as so many ebay sellers proclaim I have yet to find one! Kenny | ||||

|

| IHC Life Member RR Watch Expert |

Kenny, If the new gear wheel will physicially fit on the old arbor, it should still be useable. When you "unstake" the wheel you ruin the old staking anyway and have to restake the wheel in order to hold it firmly to the arbor shaft. After I took the scans above, I restaked the wheel and arbor back together again. I used a stake with four "legs" that would straddle both the arbor flange and the wheel center. Two sharp taps with the staking hammer on the stake and the wheel was restaked securely onto the arbor, with four new indentations holding it in place. Now, if the hub diameter and the wheel hole diameters are different, then you are back to square one. Ed Ueberall IHC Member 34 The Escapement | |||

|

I have a 21j parts watch model 3 open face. Send me the center staff measurements and I'll check against mine. Brian C. | ||||

|

All of the dimensions (hub diameter, length, etc.) are the same except for the pivot so it could likely be exchanged and re-staked. However, there is another fly in the ointment (seems to be a trend with me!). The only four-point punch I have is too small. Matter of fact I don`t have a punch of any type in either of my sets that would straddle the flange or hub. The one I have is about the same diameter as the hub. Guess I`m back to square one! Kenny  | ||||

|

On the wheel I have, the measurements are about the same as your staff. The bottom pivot on mine measures .50mm. Brian C. | ||||

|

Brian, The pivots are probably supposed to be the same. I might have made an error in my .4953 reading since my micrometer is in 1/1000 inch and I had to convert to metric. On the other hand, maybe my pivot has that much wear? I may have one of correct proportions in my inventory somewhere but I hate to rob Peter to pay Paul. It`s sometimes hard for me to decide whether a movement should be considered as parts or repairable. Guess it doesn`t matter though if you can get one working from two that don`t. Kenny | ||||

|

I searched through my "stuff" and found an 18s Dueber Grand sans balance and bal. bridge. I removed the center wheel and installed it in the Hampden. After the usual, tedious, process of re-assembling a full plate movement (went fairly smooth using the upside-down method) it is runnung great. After about 2 hours right on time! Thanks to all for your help! Kenny | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Help needed with Hampden center wheel

Help needed with Hampden center wheel

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Help needed with Hampden center wheel

Help needed with Hampden center wheel©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide