| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  NYS, 18S, MODEL 34

NYS, 18S, MODEL 34

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  NYS, 18S, MODEL 34

NYS, 18S, MODEL 34Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

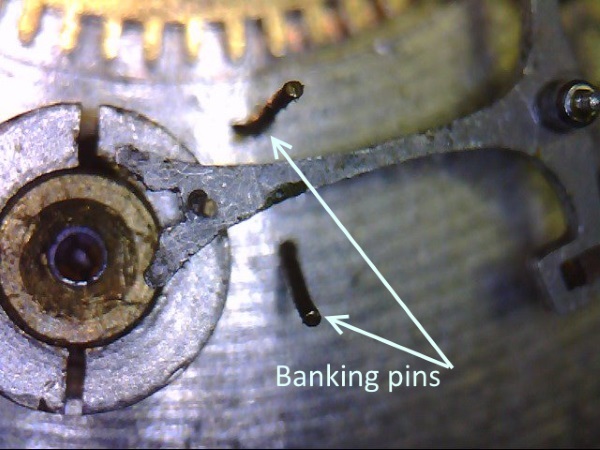

The pins are all screwed up on this unit. I have taken two photos of it. Can you tell me the spread that it supposed to be? They are bendable only and not adjustable. It refuses to tick in its present condition.  | ||

|

| IHC Life Member |

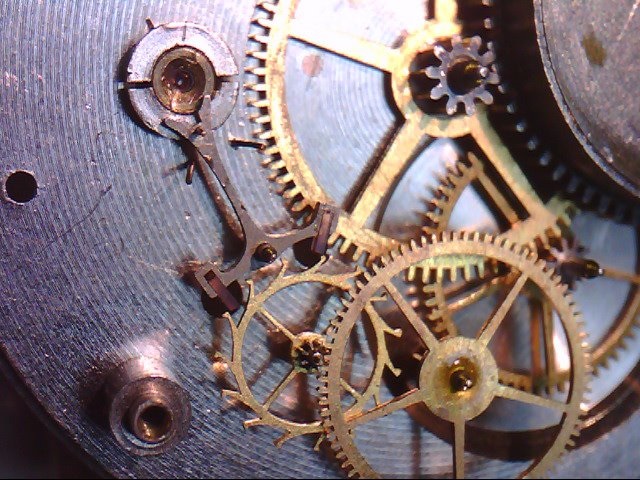

Photo 2  | |||

|

| IHC Member 1291 |

My notes I have saved regarding "banking pins", taken from publications and listening to different repairmen go something like this; I don't believe there is a set predetermined one size fits all "spread". The banking pins are there to allow proper clearance between roller jewel and fork horns, guard pin, and the safety roller. They should be far enough apart to allow the unlocking of the pallets from the escape wheel teeth at both unlockings and to allow corner freedom of the roller jewel in the lever fork. Too close and it won't run, too far spread and the balance will lose its motion. Once that is set, there should not be any reason to move them again. To adjust the "total lock", that will be done by moving the pallet stones in the slots on the pallet fork. However you must set the banking pins to control proper clearances of the fork/roller before you move the pallet stones. regards, bb | |||

|

| Life Member |

I recall something similar from one of the talks at a Horological Association of Maryland meeting. Additionally, someone there (probably one of the guys with a lot of experience) that in watches with non-adjustable banking pins, the best place to start out is with the pins as nearly perpendicular to the plates as you can get them. He said the manufacturer usually designed them so that the holes can be drilled and the pins set and all further adjustments made at the pallets. | |||

|

| Administrative Assistant |

Consolidation of information from a duplicate posting… One here in watch repair, the second in clock repair. We discourage multiple postings regarding the same item because the information can diverge and cause confusion. __________________________________________ Patrick Wallin posted July 17, 2015 17:30 Can you tell me the distance of the spread? There are two pictures of the pins. I cannot get it to tick. This is a customers unit and I would really like to get it running. The pins are adjustable only by bending & I don't want to beak one off. It's a model 34. Will buy model 34 if you have one to sell. __________________________________________ . | |||

|

| Administrative Assistant |

Response __________________________________________ David E. Booth, Jr. posted July 18, 2015 00:00 It almost looks as if the entry pallet is overbanking - in the photo it appears locked where it is, yet there is still tons of space between the arm and the banking pin. And the exit pallet looks really long by comparison with the entry pallet - almost as if maybe someone replaced a broken pallet with one that was too long, then tried to compensate for too much lock by opening the banking pins. __________________________________________ .. | |||

|

| IHC Member 1291 |

David said it well. I believe some moron of a "fly by the seat of his pants" tinkerman, has took a lazy mans approach and tried to adjust with the pins instead of at the pallets. I would try straight up/down and see how the pallets unlock and lock. Then forget about those pins and do any other adjustments to the lock at the pallet stones themselves. regards, bb | |||

|

| IHC Life Member |

Thank you all for the reply's. | |||

|

| Life Member |

@ Buster - I doubt if the tinkerer was lazy; more likely it was someone who didn't fully understand how escapements work, and was attempting to make the watch run by adjusting the wrong thing. I on the other hand, fully understand the science and mechanics, but lack the skill necessary to go messing about with adjusting or replacing pallets. If I ever feel I have advanced far enough in watch repair to do that, I want to have what the Ham radio people used to call "an Elmer" looking over my shoulder. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide