| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Calling all WW lathe experts

Calling all WW lathe experts

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Calling all WW lathe experts

Calling all WW lathe expertsGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Calling all WW lathe experts I recently purchased a Peerless / Marshall 8mm lathe and have discovered that I have a split-chuck that is "stuck" in the head stock spindle of the lathe. I know that the chucks are held in the spindle by screwing them into the draw-in spindle and I think that it is this connection (between the draw-in spindle and chuck that is frozen / rusted). I'm looking for any and all help from those that have dealt with this issue I'm considering sacrificing the chuck that is stuck by cutting a notch in it for a screwdriver blade, this would allow me to at least hold the chuck still while I try and unscrew it from the draw-in spindle. Or am i missing something entirely? Thanks in advance for all you thoughts and help! Serge Kindest regards, Serge | |||

|

They are like key fit they only go in one way. The problem is peerless collets fit a lot of lathes ,not others do not fit in peerless lathes the slot is smaller, Try some oil first,may help you out.Your screwdriver will only help hold the head of col-let | ||||

|

Hi Tom, Thanks for your help with this issue. the drawbar and collet have been soaking in penetrating oil for several days now but it has not made a difference... still stuck fast. I'm bringing this back up to see if there is any other experiences with this issue. Kindest regards, Serge | ||||

|

Can you post a picture of it? Dave Turner | ||||

|

Hi Dave, Attached is a pic of the head-stock setup. you can see the collet in the front end and the draw spindle at the rear. I have tried holding the spindle with a pair of vice grips and rotating the draw bar knob. The only thing that happens is that the knob turns in place. Kindest regards, Serge  | ||||

|

| IHC Member 1650 |

Serge Are you saying that the knob turns, but the drawbar doesn't? Turning the drawbar counterclockwise (while preventing the pulley from turning) should unscrew it from the collet. You should then be able to push on the drawbar and push the collet out of the headstock. Am I missing something? Doug | |||

|

Hi Doug, That is correct and what you describe is what I've been trying to do. I've got the feeling that the draw bar and collet are rusted together at the threads. Kindest regards, Serge | ||||

|

| IHC Life Member |

Serge, Sounds like the knob is spinning on the shaft. Looking at mine, the knob looks to be pressed or crimped on, so, with enough pressure it could spin. Steve | |||

|

Hi Steve, That exactly what's happening; very frustrated! Mine is pressed on as well to the end of the shaft and I can see it turning relative the draw bar shaft. This thing has sat in PB blaster oil for a solid week and will not budge. I know that I can get a replacement draw bar and I'm thinking that I may be headed down that road. As a next step I'm wondering about cutting the knob away to expose the shaft; that would allow me to grasp it with a pair of vise grips to see it that would allow me to give more torque on the joint to the collet... your thoughts? Kindest regards, Serge | ||||

|

Yea, mine is the same. Looks like it should not spin and was made at the factory as one assembled unit. Dave Turner  | ||||

|

Hate to say it. But looks like the only alternative is to cut if off and try and find another one! Hopefully someone will come up with a better plan. Dave Turner | ||||

|

Hi Dave, Thank you for posting the pics... I agree with you I have a feeling that the knob will have to come off as the first measure. If that does not work the only other thing I can think of is to drill thru the shaft to cut the collet threads away. The spindle is nice and smooth and the bearings have no lash /free play, it needs to be saved Kindest regards, Serge | ||||

|

Yep, that's what I'm thinking. Try to drill through it. Maybe during the process the collet will break loose and screw itself out. If you drill from the inside of the collet, if possible. Nothing to lose! Dave Turner | ||||

|

| IHC Life Member |

Serge, If you can drill through the collar of the knob then leave the drill bit in the hole for a pin, maybe it will come loose and you can save the knob and shaft. Better to try first before cutting it off. Hope I'm not too late. Maybe it'll work. Steve | |||

|

Steve, That's a good idea... have not done anything drastic yet Kindest regards, Serge | ||||

|

Try an easy out it will grip the draw bar on the inside. Will give you a good grip | ||||

|

| IHC Member 1851 |

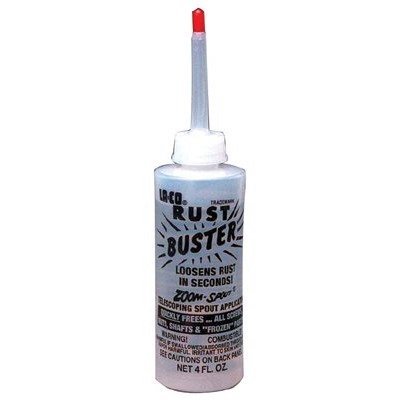

If you try an easy out, get a straight flute if you can. I've never had much luck with the spirals There is a product you might try called rust buster, it comes in a zoom spout style bottle, Most any HVAC supply house should have it. Techs use it for removing outdoor fan blades from their shafts. | |||

|

| Administrative Assistant |

| |||

|

Thank you all and Dr. Deb for the input on this issue. I'll let you know how this turns out. Further investigation of the draw bar shows that it is pulled up tight against the main spindle. It appears that this draw bar might be the wrong part? it seems short with no gap between the knob and the spindle. This may be part of the reason that it will not release. I'm going to have to cut the knob / wheel of to free the draw bar Kindest regards, Serge | ||||

|

Here's a measurement on mine. The ruler on the right side is sitting at the end of where the drawbar pulls up tight to the spindle. There is no gap between the brass sleeve that the black handle fits in and the end of the spindle. Dave Turner  | ||||

|

Hi Dave, This picture is very helpful. What I have is a bit different... the knob on mine is up against the spindle, I don't have the spacer or stop as is show on your draw bar. That's what makes me think it is the wrong part. Kindest regards, Serge | ||||

|

Friends, Finally success! It took cutting the wheel off of the draw bar shaft, as it was turning in place, which allowed me to grab the shaft with a pair of vice grips. This thing was so rusted in place that it still took several light hammer blows to remove the collet. And now to the clean up and lube phase of the project... Kindest regards, Serge  | ||||

|

Good job! Dave Turner | ||||

|

| IHC Life Member Certified Watchmaker |

OUCH to late, was going to say get one of those left hand screw removing devices, would grip inside the tube and remove it. now remove the small grub screw in the main pulley and you can then remove main shaft and inspect bearings and lube re tension. If it rusted or damage it not going to run true would just get a new lathe, | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide