| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  European Pocket Watch Forum

European Pocket Watch Forum  Whom is the maker?

Whom is the maker?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  European Pocket Watch Forum

European Pocket Watch Forum  Whom is the maker?

Whom is the maker?Related Content: Pocket Watch Discussions

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

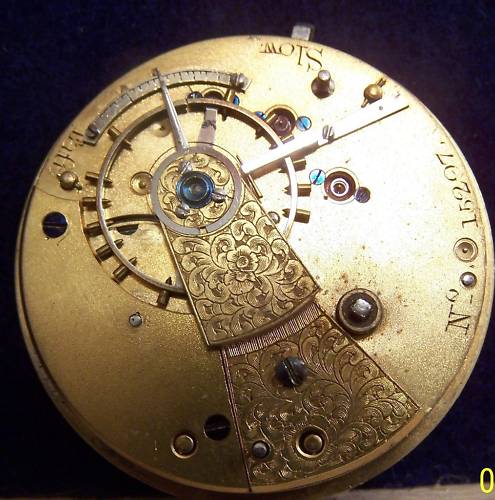

Hi all thanks for taking the time to hepling me on these issue of whom made wat. I bought it as it looked so nice and I dont have a key wind at all in my collection, but there are no marking to say "who made me" only what is there. it winds and balance works very well and is purring aways like it was made yesterday, hmmmmmm beautiful. So can any one help me out then I will have to start the search for a dial and case and hands. Many thanks every one. Francis  | |||

|

back  | ||||

|

front  | ||||

|

| IHC Vice President Pitfalls Moderator IHC Life Member |

The balance weights and jewels are funky-looking, so I'd say it may be a Swiss fake (see Shugart watch guide page 97). Best Regards, Ed | |||

|

I respectfully disagree. I see a compensated balance,and the jewel settings look like good quality. I do not know much about these watches,and can't help with the maker,but you might find more help in the European forum,because it looks to be made in the UK. | ||||

|

| IHC President Life Member |

I agree with Cecil, there is hand workmanship of quality in that movement. A balance spoke looks damaged to my eye and if so will require a proper repair. Note the "pinned plates" another sign of an early movement. We will move this to "European" with a link back to "Pocket Watches" where it began... | |||

|

Looks English and late 1800's since it has a compensated balance. Is it chain "fusee" driven? The initials RF on the plate might help to find manufacurer, just don't have my hallmark book handy to look it up. R. Glenn | ||||

|

Doesn't more information about makers and part numbers commonly lurk under balances and pillar plates? M. | ||||

|

It's interesting that a movement old enough to have the plates pinned together would have a cut balance wheel. Three jewel-setting screws on the balance cock, but none on the winding arbor? | ||||

|

| IHC Life Member |

Francis, in your teeny tiny picture in the first post of this series, you show the cover for this watch, but then you only published movment pictures. The markings on that cover would help to research this. How about top and bottom pictures of that part | |||

|

Francis, What you have there is a Fusee (chain driven) English Lever movement. Nice quality, with a diamond balance endstone, bi-metallic cut compensation balance with timing screws, and screw set jewels to the train - with the exception of the pallet staff and probably centre wheel. There may be jewelling under the winding arbor and barrel but unlikely. The arc engraved with the index will be sterling silver. One of the arms on the balance does appear damaged as Lindell mentioned, maybe you could let us know? It's very unlikely that you'll ever know who made the movement, which is a great shame when you think of the craftsmanship that went into hand creating these masterpieces, especially with and in, what would now be considered archaic facilities! Any letters found on the plates are more likely to be those of the foundry that cast them than the watchmaker, no idea if records were ever kept about such foundries or whom they supplied. The real bummer for you with this piece is the missing motionwork! It will be a Royal pain in the rectum to sort out unless you have a big pile of English lever wheels to pick around in, or have wheel cutting facilities. Trust me on this, if I'd have been charging my time out based on my former day job, that I'd whiled away playing Russian roulette fiddling around with mismatched wheels trying to rescue these things, I'd be rich! I've a whole box full of them that I've given up on and now canibalise to rescue stuff that sit on the sane side of wishful thinking. You'll need to work out the pcd of the missing minute wheel and the gear ratio to the cannon pinion, then you'll need to work out the same for the pinion that's staked in the centre, which is an added angst, because the hour wheel which should mesh with that pinion is missing! the only plus there is: you can play with whatever pcd's you want as long as the gear ratio is correct and tooth size sane! The dial will be a breeze to fix by comparison. You will need a 3x foot enamel dial and a 3x foot falseplate, which are pinned together, then pinned as an assembly to the front plate of the movement. the falseplate also carries the hinge bracket by which the movement is swung out of the case, and will have on the opposite side, the latch for opening and locking it into the case which is still on the movement visible near the bridge. As long as you can find or modify a falseplate to fit your movement, you can drill that out to suit whichever dial you can find of the right diameter. You could well get lucky with the missing wheels to turn it into a watch, but if not, enjoy it as a very good example of a master craftsman's art. John | ||||

|

Thank you Every one for the most welcome feedback.ok to cover a few points made in here. 1.Edward thanks to your comments it made me look a lot closer to the watch i spend hours going over ebay and photos an lots of Fusees trying to find if it was real or not. 2. Cecil and Lindell awesome 3.Roland Yes it is chain driven and posting pics. 4.Eric. The Balance wheel in cut photos are not very clear 5.David. The dust cover has RF on the inside and nothing else. 6. Mike. parts Number under the balance, call me a chicken but I am not ready to under do any thing on this baby just yet. 7.John I appericate all that you have said and love the way you illistrate with your words... John I have a few questions for you on this. What is PCB? How can one work out the gear ratios as well? before I forget three balance weight on left side seem to be cut in half. | ||||

|

I cannot seem to upload photos of the chain or any thing else are the Res is too big. I have changed all my photo setting to small as possbile but cannot get them below 1.2mb..... | ||||

|

Francis, many thanks for your kind comment, for your questions, I'm going to try keep it simple and general as I can. PCB is an acronym for 'printed circuit boards' I think PCD though, is 'Pitch Circle Diameter' which is where the fun starts! If two discs are running against each other, the outer diameters of the discs can be said to be the PCD's. Where gears are concerned though, it gets a bit techy and makes my head hurt, so hope you don't mind me not getting in too deep, it'll avoid me reaching a point I need to chuck the spade away! Because the outer diameters of gear wheels actually run 'inside' each other, the 'pcds' are further into the wheel. So, taking a look at a typical pair of gear wheels, you'll see a point where the teeth touch when one pushes the other wheel around. The point where the teeth touch, and viewed on the wheel as a whole for the purpose of gearing, is the theoretical gear pcd' The part of the gear tooth that extends above the pcd - into the root of the associated gear, is called the 'Addendum'. The part of the tooth below the pcd, is called the 'Dedendum', the base of which is the Root diameter. The 'Addendum' of a gear is also smaller than the Dedendum to provide the working clearance. The motionwork consists of 2x individual gears and an assembly of a pair, these work in two layers which operate together. The bottom layer consists of the steel cannon pinion gear and the large brass minute wheel. The minute hand fits on the end of the cannon pinion - a square in the case of your watch. The second layer of gears on the motionwork sits on top of the first layer and is driven by the bottom pair, with the cannon pinion as the driver. These consist of the steel pinion in the centre of the minute wheel and riveted to it, plus the large brass Hour wheel, which is formed with a pipe onto which the hour hand fits. For the gearing ratios of the motionwork, this is calculated around the fact that on a 12 hour dial, the minute hand will fully circumnavigate the dial 12 times for the hour hand to do the same Once! Or, put another way, for every full sweep of the minute hand, the hour hand moves 1/12th of a rotation - which equals one hour. On a 24 hour dial, the minute hand will rotate 24 full sweeps for once of the hour hand etc. So, for a 12 hour dial the gearing needs to be 12:1 and arranged by the numbers of teeth and sizes of wheels - which in a watch is limited by the space available! As the gears are in two layers, we can assume very simplistically - and not necessarily workable, the the bottom layer will have a ratio of 6:1, where the cannon pinion could have 10 teeth and the minute wheel 60 teeth, which means the cannon pinion would have to rotate 6x times for once of the minute wheel. Ditto for the upper pair of gears also 6:1, where the minute pinion could have 10 teeth and the hour wheel 60 teeth, meaning the minute pinion would rotate 6x times for once of the hour wheel. So, unless I've shot my feet off and got it totally wrong, this should give a theoretical 12:1 gear ratio from the cannon pinion to the hour wheel. Phew, having got that out the way, and thinking about the simplest and cheapest method to fix your watch, I'd suggest finding a complete motionwork set, where the cannon pinion will fit or can be made to fit the centre wheel post of your watch, and then re-plant the post for the minute wheel removing the one there already. As such a pair would already be matched and of known value, so it should work Purists hate this sort of thing, but as you'll be very unlikely to ever find anything to fit as a set, it's a better option than scrapping what could be a Very nice watch. The only original part you would be removing is the stubby little pin on the dial plate. OK, I'm off to lay down in a darkened room, I'll leave it to you to ponder its fate....... I'll try sort some photo's out to support what I've written. John | ||||

|

John thanks I think lol. Ok wow that was pretty intense and I am amazed that u didnt take a box of bex powders after that lot, I know i would of had too. I have worked out my camera where i can get the pixel down as low as possible and still get some realy good clear images. but that will have to wait till tomorrow. I still have reread wat u posted so it sinks into the old scon. I knew u had to be britt, ur way with word.Ok I will post photo tomorrow AEST once back from the quacks, quartazone injections wat fun. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide