| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  European Pocket Watch Forum

European Pocket Watch Forum  DIY watch repair

DIY watch repair

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  European Pocket Watch Forum

European Pocket Watch Forum  DIY watch repair

DIY watch repairGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hello Folks, I think this is a working mans watch , bought it on e-bay a couple of weeks ago , Its not working, there are no marks, but I would love to get it going again if possible, the fob is of a welsh lady, I have been reading books on watch repair lately, and I may make this my sacrificial lamb, got to start somewhere, any help or advice most welcome , when I was a young man there where watch repairers on almost every road , they are now as scarce as bobby horse droppings, found one in town he couldn’t he be bothered to open it , Soooo D I Y Cheers to All Les, p/s still learning the photo bit, please be kind, | |||

|

1  | ||||

|

2  | ||||

|

3  | ||||

|

4  | ||||

|

5  | ||||

|

Les, for an eBay watch, it appears to be in quite good shape! The reason your jeweller didn't open the case was probably because he didn't know how, most of them now farm out repairs to a jobbing repairer somewhere anyway, and pay them a fraction of what they'd charge you. The movement is a low jewel count Swiss cylinder type, so probably as good as any to start with, being fairly uncomplicated. Before you go digging around in its guts though, a few questions ......... Is it fully wound, or does the key wind mechanism turn quite freely - clicking away on the ratchet without winding up? Is the balance good, and rotating fairly freely, or does it flop around when you rock the watch? If the balance pivots or cylinder are broken, forget it, these are grief to fix even for well experienced repairmen! What sort of tools do you have to hand for watch repair? John | ||||

|

Hello John, You’re a harbour in a storm, the watch is fully wound, the balance moves if I move it with a driver forward a touch then it bounces back I am not to bothered about losing it, but it’s a challenge, I will take a photo of what I have at present in the way of tools, I am 80 now john so I don’t have time to waste, I try to keep my mind active, and if I can achieve this then I shall have something to boast about, I have been doing my genealogy over the past 10yrs or so got back to 1785, now my great uncle John Tasker married Henrietta Ellis in 1843 the daughter of John Ellis a watch maker of this town, can’t find him, have you ever come across any one of that name, Thanks again for your reply, All best wishes Les  | ||||

|

Les, you'll probably outlive me and I'm 20 years behind you yet You've probably got enough basic tools there to play with this watch to kick off with, but youll need some cleaning fluid and a spot of oil for it. The mainspring is fully wound and will be 'set', most likely blued steel than alloy, and is a common fault. When you pull it out of the barrel, it will stay coiled fairly close instead of springing open. Useless, but I can probably fit you up with a new one. There's a couple of Ellis's listed for Liverpool in my books: John Ellis, 1834, Clock dial enamellers. James e. Ellis, 1848, Wholesaler. Either of them or relatives could have been involved in watch or clockmaking at some point. Might be worth trying to find where they originated too, as they may have moved to Liverpool from elsewhere. Quite a few Ellis watchmakers in Cheshire Yorkshire and Lancashire that could have drifted over there. I'll come back on the watch a little later. John | ||||

|

| IHC Life Member Site Moderator |

Les There was a John Ellis born about 1796 & married to a Henrietta Ellis born about 1821 living in Liverpool in 1841. John was listed as a watchmaker, at that time they didn't list any children living with them. Tom | |||

|

Hello Tom, you have found them, They are father and daughter, I had a copy of the Liverpool Mercury off the gen; site, she was listed as the only daughter Thank,S TOM | ||||

|

| IHC Life Member Site Moderator |

Hi Les I emailed you a copy of the census. Tom | |||

|

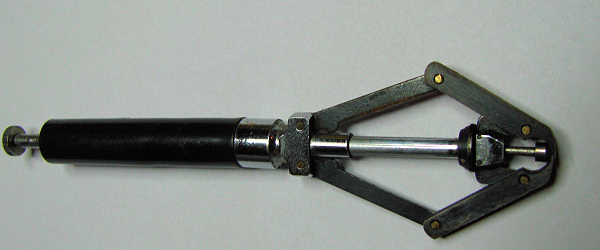

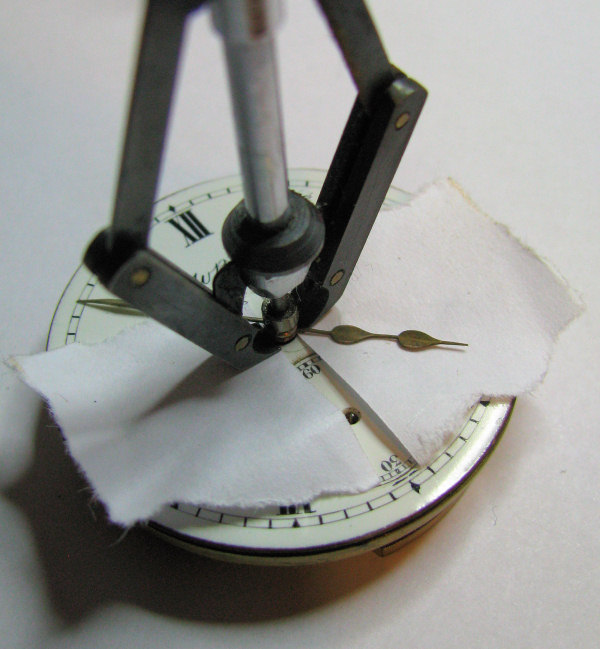

Great find Tom, Well done! Les, If you're still inclined to have a go at resurecting this watch, I'll make a start with what you need to do! As this watch has a snap on bezel, I'd be inclined to take it off and remove the hands first, it'll help avoid accidental damage to them when removing the movement from the case. The pic's below show a couple of options for removing the hands, either cranked levers or proprietory hands pullers. Please don't be tempted to pry the hands off with a screwdriver, you'll either mash the back of the hour hand, chip the dial centre hole or both, and almost certainly bend something! The hands Must be pulled or levered vertically, otherwise you will bend or break the centre pin that the cannon pinion is staked onto (Don't worry all will become clear)! Ditto the seconds hand, as the pivot will either bend or snap like a carrot! Whichever method is used, I always place a piece of paper or card between the levers and dial to help protect the dial face, and place the hands 180 deg apart, positioning the levers clear of the centre seconds sink (risk of chipping the dial edge otherwise)! John  | ||||

|

Hand pullers in use! JW.  | ||||

|

Cranked Levers, these are simply small diameter steel rods with a flat filed on them, then bent at the ends. Simples! JW.  | ||||

|

Levers in use, I even found a Benson movement to show them for you! JW.  | ||||

|

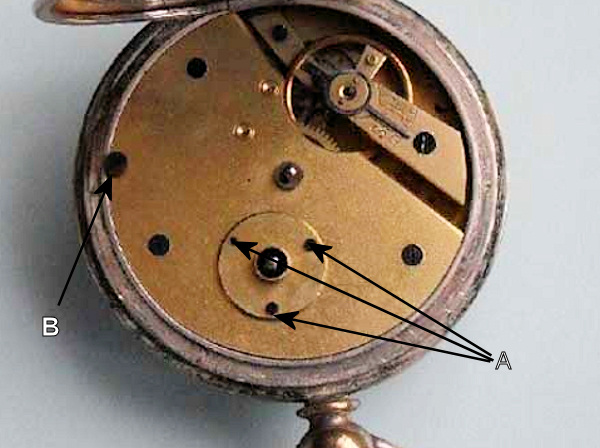

When the hands are removed, you then need to get the movement out of the case. I've editted a copy of your photo to show what needs taking off. Remove the single screw (B), and gently push the movement out of the case. It will pivot, as there's a locating pin on the movement on the oposite edge to the screw - this pin tucks under the lip on the case band, and positions the movement and dial in the correct orientation to the case pendant! JW.  | ||||

|

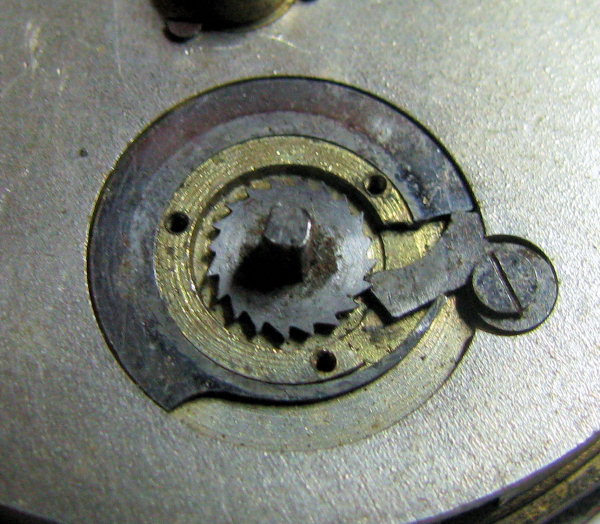

Next thing you need to do, and before Anything at all is done to the movement, is to let down the mainspring - this is Especially vital on any Cylinder movement! Remove all screws (A) from the dust cap covering the winding square, and lift off the cap. Check also if there's a broken screw left in the empty hole, or if there are threads visible! Under this cap, you'll see a 'circlip' type spring, a ratchet toothed wheel and a 'click' which will be engaged in the ratchet wheel. I usually use a small pin vice for the next operation, but you have a key, which is ok if care is taken! Turn the key square as if winding the watch, this is to remove the spring pressure on the click. Ok, now into 'one armed paper hanger' mode! Hold the 'click' clear of the ratchet wheel, and gently allow the key to Unwind. Beware! It is Very easy to let the key slip out of your fingers allowing the barrel ratchet to skip several teeth, so take it half a turn at a time, each time letting the click re-engage the ratchet! You'll get the idea when you try it! The spring may be stuffed, but it's still got enough grunt to do damage if it gets away from you! JW. | ||||

|

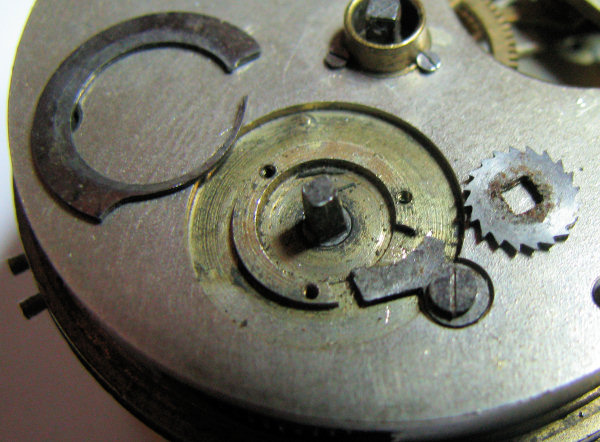

The next few photo's show what you should find under the dust cap! Apart from small differences in the spring and click size, all these Swiss cylinder types use pretty much the same arrangement. JW.  | ||||

|

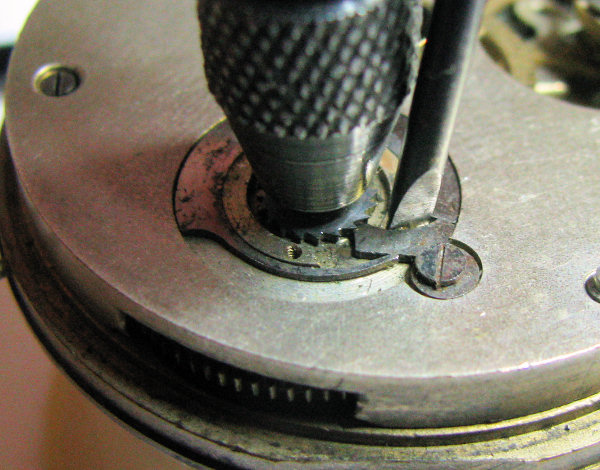

The next shot gives some idea of the task in hand for letting down the spring. I'm using a pin chuck here, as it can slip through the thumb and fingers giving more control whilst the barrel is unwinding. The movement has to be held secure, you have to slowly let the key / chuck unwind, And control the click, Not letting anything get away! JW.  | ||||

|

Everything unwound and taken off! Most ratchet wheels just lift off (after you've got any sticky crud off the square that is!). However, if it's Not your lucky day, it'll be the less usual type that has the square and ratchet wheel as an assembly, which is screwed into the barrel hub which carries the hook that winds the spring! Hopefully yours will just lift off! JW.  | ||||

|

| IHC Life Member Site Moderator |

Great job John & photos, very easy to understand. Tom | |||

|

| Powered by Social Strata | Page 1 2 3 4 |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide