| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Drill hole in mainspring end?

Drill hole in mainspring end?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Drill hole in mainspring end?

Drill hole in mainspring end?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Anyone ever tried this? According to the Mainspring Repair Section in Fried's The Watch Repairer's Manual this is a legitimate procedure. The reference is to use a diamond bit. What sort of bit should I shop for? And could I use it in a Dremel? Dave Turner | |||

|

| IHC Life Member |

Dave, I would say yes you can use a Dremel but they don't have much torque and are pretty fast in RPMs' I use a 1/4 HP Foredom. 0 to 22000 RPM. Even at 500 RPM it can't be stopped. Any way you are probably looking for a diamond bit. A regular drill bit will walk all over the spring before you can get it to drill the hole. The bit you seek is a bit that has been coated with diamond dust. It is not a high speed bit and will burn up if you exceed it's rated RPM. If you go slow and use a lot of spit for a lubricant it will work. Oil will just clog the bit up. Believe it or not the instructions that came with my diamond bits set recommends spit. Actually I think you best bet would be to get a MS punch. Dashto has some or look on Ebay. Or you can try a cone shaped diamond bit in a drill press with the spring locked in position for drilling. I still think even that would walk on you. | |||

|

| IHC Member 1610 |

Yes I have heard of this. I don't do Unless I can't find a mainspring. Mainsprings are cheap. I try to get the white alloy mainspring if I can. Usually around $18 and that includes shipping. Blue mainsprings are even cheaper. But if you are going to use a diamond coated drill the biggest problem is heat. Heat will destroy the tiny diamonds. The best way would be to hold the mainspring slightly under water and put the drill into the water and turn it on and drill while it is under water. Messy? You bet it is. Another reason I will just buy a new one. | |||

|

| IHC Member 43 |

All, When drilling a spring, dimple it with a center punch first and the drill will not wander off the hole location. Curly | |||

|

Thanks for the advice guys. Sounds like a lot of tedious work. I would just like to know that I could do it, if I tried. Dave Turner | ||||

|

Dave dimple the spring and use cobal drill. just watch the RPM not to fast. | ||||

|

I have tried this, but I then have the problem that the spot I drilled is not easily made into a small loop to go around the arbor. It is most often brittle and will snap off. I usually just get a new spring to avoid this. | ||||

|

| IHC Life Member |

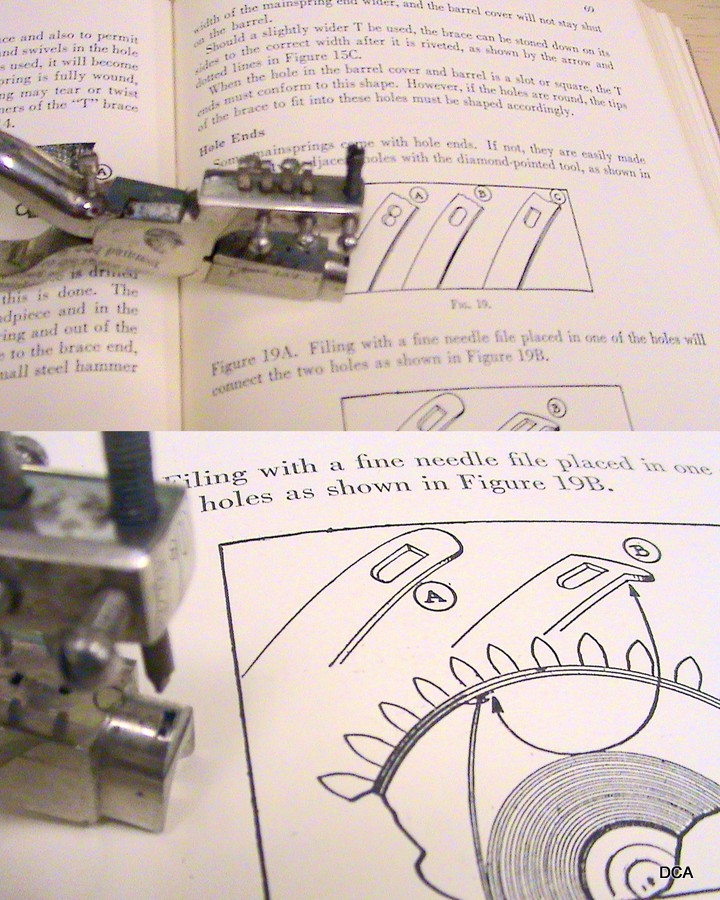

I use a punch to make holes at the outer coil of the mainspring if necessary to get it working. This tool has to be in good condition, but will do the job "cold" and leave a good end to catch in the barrel. The photos below show this tool in the foreground to the Fried notes about drilling which are for that purpose as well. Trying to make a hole at the I.D. of the Mainspring coil is something I prefer to avoid as a break in that area means you are left out in the tempered section of the mainspring.  | |||

|

I agree with Jim. I tried this once and the spring shattered. Too brittle. I think the book says that you have to heat the piece up so to make it soft enough to work with, then temper it again. I saw the drawings for this when trying to add a "T" back to the end of a broken mainspring. At least if you get a new one it would be the right length and it would still have some tension in it, but if you get it to work ... then you can start collecting recycling credits | ||||

|

Dave, What you have described is exactly what I need to do. On the outer end of the mainspring. I bought a cobalt drill bit today, but the smallest I could find was 1/16" ( a little too big ) Hmmm, guess I'll have to shop for one of those punches you show pictured on the book. Here's one I found on the bay: http://www.ebay.com/itm/OLD-MA...&hash=item337c5e2640 I could buy about 10 new mainsprings for the price of this one. A picture is worth a thousand words. Didn't know they made such a punch. Dave Turner | ||||

|

At the place where I worked for 41 years the last few years I was there we made carbide circuit board drills, all had 1/8" shanks and the diameters went from as small as .015 diameter on up to almost an 1/8 these would drill through almost any thing. I have used these to hand drill through a blue mashed fingernail to relieve the throbbing pressure. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide