| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Are all Rockfords this solid ?

Are all Rockfords this solid ?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Are all Rockfords this solid ?

Are all Rockfords this solid ?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

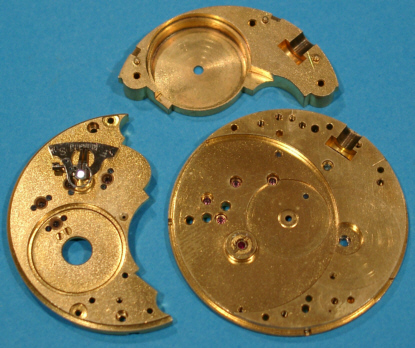

I needed a new watch to play with so I called for volunteers and this 18 size Rockford got pushed out of the box by the others. I took it apart and was suprised by how solid the plates are. No pillars in this one as the plates come together at all the joins. No need for a dust guard around the outside as there are not many gaps. Here is a shot of the 3 plates.  | |||

|

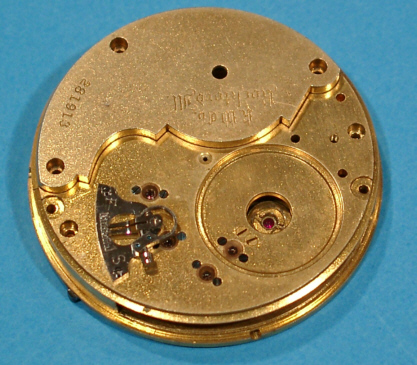

One of the things I sometimes find difficult is getting the escape lever back in position on a full plate movement as you re assemble it. You have to get the end back into the gap between the top plate and the bottom balance jewel and you end up looking between the plates and moving the shafts around with little hooks or prods. This one is so different and I like the way it works. The bottom balance jewel is on the bottom plate and this makes things so much easier. Note also the way the balance jewels are held in with a threaded collar rather than 2 screws. The top one is the same. I am not sure if this arrangement is better but it is different so I thought I would share for those who have not seen one. Here is a shot of the plates assembled.  | ||||

|

Stephan: This movement is constructed like the 18 size Waltham 1892 model in that there are no pillars as such-the plates are solid blocks and sort of slide together. (Also both models have a recessed balance so someone was inspired by the other)! Full plate movements are assembled with the upper plate below and the main plate above where you can get the center and 4th wheels in place and aligned first to aid in reassembly. Like anything else it takes a lot of practice and yes, the pallet fork and arbor are tricky. I remind myself that the folks at the factory did this every day! | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide