| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  3D printing industries

3D printing industries

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  3D printing industries

3D printing industriesGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I have been printing some dial on 3D printers but this great read to all. Some pocket watch parts can be now revers engineer http://3dprintingindustry.com/...nting-mica-freeform/ | |||

|

| IHC Life Member |

The puzzling thing is that most of my prototype 3D designs have been made on "3D Printers" since about 1995. Where this is going now is (I Guess) with the larger "Macro" stuff. We were printing complete mechanical sets then, but most of it was within a 6" x 8" x 12" Space. Small watch parts is a good application as they can be done quickly. Then there is photo-etch . . . VERY Lo-Cost.  | |||

|

photo etching is no cost effective if you have to do one part and can't be done at your place(home) 3d printers are being less expensive and are making it way to average Joe's home. | ||||

|

| IHC Life Member |

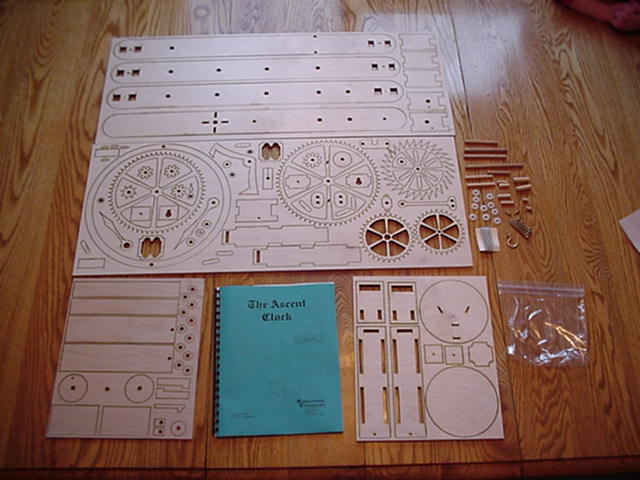

I SUSPECT THAT IF WE WORKED UP THE ARTWORK, WE COULD MAKE A SINGLE PHOTOETCH NEGATIVE (MUCH LIKE THE "ASCENT" WOODEN CLOCK KITS OR LASER-CUTTING) PROGRAM THAT COULD MAKE A COMPLETE WATCH PARTS WHEEL TRAIN, SPRINGS, HANDS SET. THE STAFFS WOULD HAVE TO BE MADE FROM WIRE CONVENTIONALLY. ADD STAFFS AND A 3D CASE AND WE COULD HAVE AN IHC185 "CLUB" WATCH.  | |||

|

Whats withe the caps lock? as some might take it as a screaming or are you? | ||||

|

| IHC Life Member |

NO screaming, I hit that by accident sometimes and the PC's have no warning for it. | |||

|

| IHC Life Member |

I run a small 3D Printing Lab. We do mostly ABS, and consider 1mm the minimum feature size. For mainstream "3D printing", watch parts are just beyond reach. I did have a student make a very credible *clock* a few years ago. Kenneth Sloan | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide