| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Triple signed Burlington "Pig in a Poke"

Triple signed Burlington "Pig in a Poke"

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Triple signed Burlington "Pig in a Poke"

Triple signed Burlington "Pig in a Poke"Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

21 jew. adj5pos.s/n3530182=1919 mod.9.Montgomery dial..Burlington case with Eagle over arrow and shield. This was supposed to be non-running and a frozen back case.Took a $81.25 gamble and I think it paid off.Watch runs well and case back is a little tricky to get on and off.I believe this to be RRG is that correct? Regards Roger  | |||

|

Dial | ||||

|

movt  | ||||

|

case back  | ||||

|

another  | ||||

|

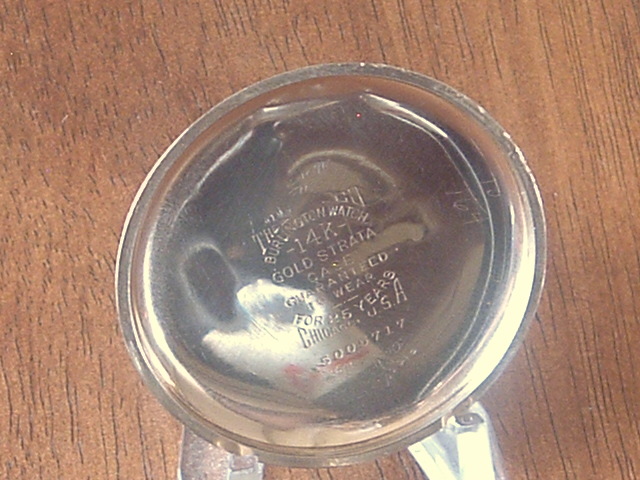

inside case  | ||||

|

| IHC President Life Member |

CONGRATULATIONS ROGER! That's about as good as it gets my friend! Lindell | |||

|

sold similar last week for 220 on the bay, you did well. | ||||

|

| IHC Life Member |

A wonderful altogether collectible. Maybe the seller could not find where to put the battery! | |||

|

Thanks guys.This makes up for a few "Pigs in aPoke'that turned out to be a"Poke in the Eye" | ||||

|

Just a question, but do all the case numbers match? The back looks like its on upside down, but that could be because the back isn't tightening down all the way as you say its tricky to get on. Even if they dont match its a very nice pickup for the price. The movement and dial alone are worth that, perhaps even the dial alone as it looks better than most I have seen. | ||||

|

| IHC Vice President Pitfalls Moderator IHC Life Member |

Nice find Roger, you don't often see a Burlington dial that nice. Best Regards, Ed | |||

|

| IHC Life Member |

Very nice Roger! Deacon | |||

|

Jim the case numbers match.The case back has a small dent in it near the threads.I think that is why it is difficult to get on and it doesn't tighten down completely leaving a small gap and the back about 1/2 turn to be under the stem correctly.Hope to correct that.Any suggestions?Thanks Deacon and Ed for your comments. Regards Roger | ||||

|

| IHC Member 1291 |

First let's examine both the case body and the case back under hi viz light and a 10x loupe. Looking for any cross threading, damaged, or residue caked in the threads. At this time thoroughly clean both sets of threads. I would use a stiff bristled toothbrush to clean them well using degreaser, then soap, then hot water. I would then use OOOO steel wool on both sets of threads and rinse in hot water. Completely dry the threads on both pieces using the wife's hair dryer if available. Afterwards try to screw the back on again if no damage is seen and the threads are clean and dry. It's important that the threads on the two pieces are completely dry as any moisture may create a vacuum that could make it extremely hard to remove if it now screws down tight AND if allowed to remain tight with moisture present, rust may set in making it even harder to remove. If at this point the back stops at about the same place as before, then try a fingernail around the gap and see if the back "pops" up anywhere. If it pops up somewhere, there is a cross thread problem, perhaps slight and perhaps major. If it does pop up then see if the lid will now screw down completely. If we are back to batting "zero", take the front bezel, IF the numbers do match, and see if you can successfully put the front glass bezel on the backside of the mid frame and screw it down completely. If that works we probably do have a problem with the back cover. Report what you find, as we aren't thru regards, bb | |||

|

Buster,thanks for your help.The bezel screws on the back with no problem.I have cleaned case back and case threads well even though they didn't appear to need it.I gained about a quarter of a turn and the gap is all but gone except upclose to the top starting right before the stem and ending right after the stem.AS I said thanks a million for all your help.Regards Roger | ||||

|

| IHC Member 1291 |

You are most welcome !! When you started you had a gap and were 180 degrees off, now the gap is hardly seen and you are 90 degrees off which is good improvement. It can be taken down further and make the back design fit straight up and down in line with the stem. This may be accomplished with some fine valve grinding compound available at auto parts stores. You only put a very small dab on the case body threads, I said a "touch" small amount !! Then you crank up the eazy chair and watch your favorite NFL game tomorrow and tighten a bit at a time, back it off and tighten again, back off etc about 200-300 times and see if you can get that design straight up and down. You may want to use a jar opener gripper to help you. The key is a little bit of tighten at a time and then back off, we aren't trying to get it screwed down tight all at one time. You are actually lapping old threads and getting them back in shape. After you are thru, clean the valve grinding compound off both pieces using the degreaser and soap and hot water and drying technique and give it a try. After the game [which is 3 hours] let us hear where you are at and give us a picture of the design now, and where it fits after the game. If we are closer and the gap has disappeared, we can go the final step to get the design to fit straight up and down if so desired if you aren't already there. regards, bb | |||

|

Thanks Buster,I will do that today and post my results.Now I have a good reason to be lazy and watch the game!! | ||||

|

Boy!My hands are exhausted!!I believe the gap is gone but it is about 20 degrees off center.Pics to follow.  | ||||

|

second  | ||||

|

gap?  | ||||

|

gap??  | ||||

|

| IHC Member 1291 |

That is magnificent Roger !! If the threads are EZ off/on, that is where I would say FINISHED !! That's about where that design would have been when the eagle flew out of the factory !! They did that so that wear would put it straight up/down over a period of years. regards, bb | |||

|

Thanks Buster,Hope I don't get anymore like this.The game was lousy as my team lost!! | ||||

|

| IHC Member 1423 |

Where else but IHC 185 can you learn things like this? Great stuff! Charlie Hodge | |||

|

| IHC Member 1736 |

I can't thank this crew enough for the great ideas. I've lapped valves before and never would have made the mental connection to using this process to salvage threads. I recently acquired a 16s Studebaker 8p with a bad staff and a very low mileage sceptor base metal RR style case. The back cover of the case was cross threaded and there was no way it was going on without a lot of TLC. I used my 160 light blue banded screw driver laid parrallel to the thread valley and walked it around the threads several times, using it as a graver to shave off the rolled over and dimpled parts of the threads. This gave me enough engagement to get the bezel to start about a half a turn. Then it was time for the lapping compound. After about ten minutes of back and forth, it became obvious my hands were not going to survive three hours of this process. So I went to the local craft store and bought a mixed pack of those suction cup thingies you use to hang ornaments or accessories in a window or on the bathroom mirror. This worked like a champ. It even had a little nub on it I was able to use as an indexing indication so I knew I was making progress. | |||

|

Paul what a great idea using suction cup thingies for this .Will try it. Thanks Roger | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Triple signed Burlington "Pig in a Poke"

Triple signed Burlington "Pig in a Poke"

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Triple signed Burlington "Pig in a Poke"

Triple signed Burlington "Pig in a Poke"©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide