| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Staff Manufacturing

Staff Manufacturing

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Staff Manufacturing

Staff ManufacturingPage 1 2

Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Good Morning Everybody, When replacing a staff I broke a lot. I suppose I will able to make them at my company. We have a small SCHAUBLIN CNC lathe that we are using for very small high precision parts. The cost of these staffs will be very low. I can give them to the club administration for to sell to our members. In this way we will support also our club. I want to start with the easier 18s Waltham and Elgin staffs. The problem is that I need original blueprints. Is somebody can provide me correct drawing of these staffs? I have electronic measuring microscopes able to give me the drawing of staffs. But as I don't know the origin of these parts, I can't trust to these drawings. Thank you, Bulent Ogel | |||

|

| IHC Life Member Site Moderator |

Good Morning Bulent If you click on this link for our site it might have the information to get you started. Tom https://ihc185.infopop.cc/eve/forums/a/tpc/f/7576090143/m/5056082095 | |||

|

Like a treasure. Thank you Tom. Bulent | ||||

|

| IHC Member 376 Watchmaker |

Bulent that sounds great i would check the rockwell hardness of the staffs you make and compare them to some originals,,too soft and the pivots will wear out and too hard they will break easy..I do have some of the hard too find staffs if you need some dia.s sometime i would be glad to email them or send you a example..some staffs like the ones for the model 5 seth thomas and the ones for the early model 1857 waltham,s just too name a couple are very hard too find... I would try too work from original company made staffs for the measurements ,,Some of the what i call after market staffs made several years ago were not of very good quailty ,,the hub,s were either too small or too big ,you might break a roller table or it would just fall down on the staff. I do hope you have good luck with this.. | |||

|

Maybe this will help too. Larry | ||||

|

| IHC Life Member |

Bulent, I have the staff dimension book done with Mr. Townsend's carefully researched staff dimensions including the SHAFT TAPERS REQUIRED for many American Pocket Watches. I could scan that and send it to you too. This is one of the 6 pages of Howard (which are almost all "special" before the Keystone Howard Period) drawings; | |||

|

Wow! We sure have a lot of information huh? Bulent, This is so exciting! What a wonderful thing to do for the members. THANK YOU! THANK YOU! Sheila | ||||

|

| IHC Life Member |

Bulent...Being able to get staffs made at a reasonable cost would be a HUGE benefit. Even if one finds a new old stock staff there is a good chance it will have corrosion on it. I hope your project comes to fruition! Roger | |||

|

Thank you to all for your assistance. I want to inform you that I am not looking to this project as a new business. Just part of a hobby. Roger you are right. I look to my staffs at microscope at 30X. Mostly they have corrosion. The material is not stainless steel. I am planing to use SS material. What is the source of staffs on the market? NOS? Or is there manufacturers? Thank you. Bulent | ||||

|

| IHC Life Member |

Bulent...As far as I know, unless one makes their own staff, the only ones available are what is left from old stock. Also, as you consider material to use, I'm not so sure stainless steel is the best choice. Don't forget the balance must be riveted to the new staff and the roller table must be pressed on as well. Stainless may be too hard. I'm sure others with more knowledge on the subject than me can advise. Roger | |||

|

Samie, I have also the equipment of measuring the rockwell hardness. But the staff is too small. How I will hold it? If you know the hardness value, please give it to me. Today we did a meeting with some technical persons in the company about my project. We examined a staff on microscope. The pivot size was 0.15 mm. According to them, machining of the pivot will be very difficult. We will see on next week. Do you have a complete drawing of this early model 1857 Waltham. We can start with this one. Bulent | ||||

|

| IHC Member 376 Watchmaker |

Bulent not sure about the hardness as was mentioned the hub that goes in the balance wheel is softer than the pivots so it can be riveted ..Most of the railroad staffs are 0.10--0.11 and 0.12mm you won,t see very many staff bigger than 0.13mm ..Although i have some 18 size elgin staffs that are 14 and 15.. Somewhere i do have the dia,s of the model 1857 staffs i will find it this weekend and email it too you..I bought 12 of these on ebay last year and with a little rust on them i still had too pay 22.00 each in order too win the auction. | |||

|

David: I would like to get a copy of Mr. Townsend's book. Is it still in print? Does it have an ISBN number? Thanks | ||||

|

| IHC Life Member |

The isbn number is; 0-913902-52-7/Paperback The cover looks like this; | |||

|

| IHC Life Member |

This is the first of 3 pages of Waltham staffs, i don't know which one is the 1857 | |||

|

| IHC Life Member |

Pg 2 Waltham staffs | |||

|

| IHC Life Member |

Page 3 waltham staffs | |||

|

David thank you very much for your posts. I perceived that I have already a copy of this book. Today we started by 18 size Cat No 1364 staff. Now we are making detailed drawings. This week we will adjust one of our wire spark machine to 0.1 mm wire and we will cut some cutting tools for the lathe. And we will see the result. I will inform you about results. Bulent | ||||

|

Don't mean to sidetrack this discussion, but being new to this, could someone describe how these parts were originally made? If a SCHAUBLIN CNC has difficulty making these to original size, I am having difficulty understanding how they were made with machines that were not nearly as precise? | ||||

|

| IHC Life Member |

Actually Bruce, Regretfully, "CNC" is not the answer for most repetitve high volume manufacturing jobs, and it will never be. The original machines that made these watch parts in the late 19th century-early 20th century were more precise in their repeatability of part quality than any "CNC" can achieve in high volume production. My work within the last 30 years (when we were STILL PROUD OF "MADE IN AMERICA") also included facilitating US rights to applications of Imas Dellorto rotary manufacturing systems with Bill Kuban, my very good long time associate, friend and owner of Kurt Manufacturing Company, Minneapolis, MN. People like us worked long and hard on development of high volume precision single-line Made in USA manufacturing systems from 12+ complete 5.56mm cartridges per second to 800+ Ford V8 engines per hour and 2,000 Singer sewing machines per day. While many machine shops use CNC equipment now, true high volume production like the above cannot wait for those control systems and is still usually "hard programmed". The only advantages over the past are that we have are better alloys and tool-setting technology which shortens the machine and setup times. As for the accuracy, we have gone virtually nowhere since before WWI. An exception is (in my experience) with the foolishness of Nuclear devices, but the cost of that accuracy is hardly manageable in a "sane" world. end of lecture | |||

|

| IHC Life Member |

Here is some information from an old K&D book I have: "Factory-made staffs are turned out complete from the soft steel, then hardened and tempered; the requisite finish being given to the pivots, etc., afterward. On the regular factory staff, absolutely no turning is done after the staff is hardened and tempered. This method of manufacture makes it possible, even desirable, to leave the temper of the staff harder than it is practical to make hand-made staffs" The book doesn't say how the "requisite finish" was done afterward. | |||

|

Thank you Roger. Very important information for me. Bulent | ||||

|

Dave, Staff numbers 277,278,279,280 and 281 are staffs for the Waltham 1857 model. Staff numbers 280 and 281 are the hardest to find. Bulent, keep trying, we need these staffs bad. Brian C. | ||||

|

| IHC Life Member |

Bulent, It is interesting that my friend in Waltham says that the staffs wer "flash tempered, and that made the pivots very hard but the bodies remained soft. If you do steel, try to get to a Brinell Hardness of 555. (about 55 Rockwell C) If you do stainless try ISO 683/XIII Type 11 (304 sst) It might work ok if we can get the polish high enough. I am most concerned with the press fitting dimensions. | |||

|

David, today we did some machining tests for to see which pivot size we can get correctly. Up to 0.150 mm the result is verg good with a tolerance of +- 1/2 microns. Under 0.15 mm this tolerance become bigger. At 0.12 mm we got +- 10 microns. I suppose when we will these machining tests with the final cutting tool, the result will be more better due to the large radius at the end of the pivot. Don't be concerned about the press fitting dimensions. At this point there will be no dimension problem. Bulent | ||||

|

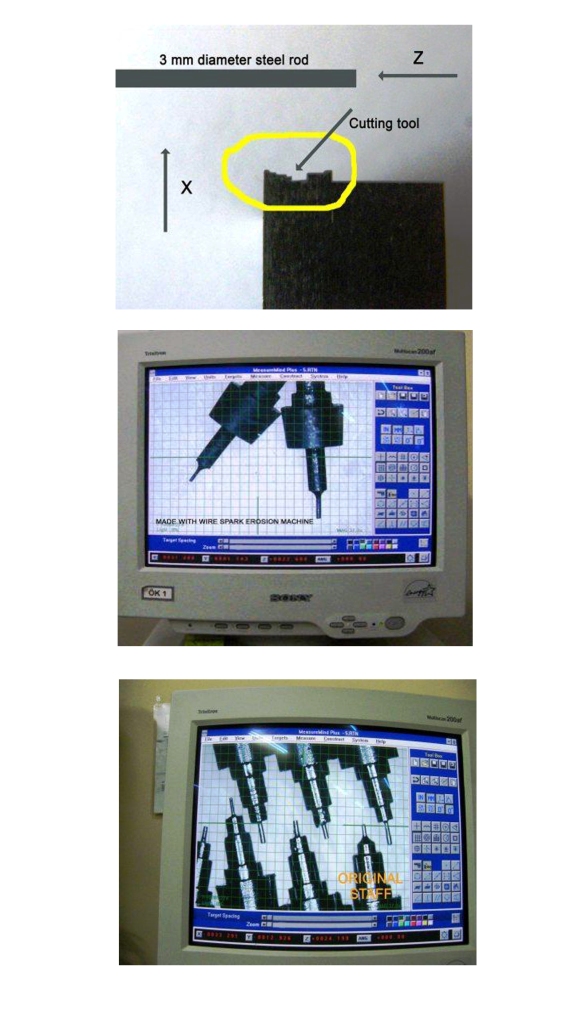

Today we worked hard for staff production. (Me + 5 persons.) We cut the tool on wire machine and did a test machining on the Schoublin lathe. This don't work. When approching with X axis, the rod is broken after 0.5mm of machining. The material was the only we found in house. 3mm diameter rod BOHLER K510 (1.2200) Very soft. Then we test to make 2 staffs on wire machine (EDM). By turning the part. Very special application. Parts are perfect. Machining time was 30 minutes.The houre of this machine is $100. $50 by staff. Not possible. Then we tested again with the lathe by using standard cutting tool and approaching from X axis. The purpose of this test was only to see if we will be able to cut pivots with acceptable precision. The result is good. We are within 5 microns. The second step is to machine the other side of the staff. For this purpose we ordered some holders and tools that we will receive after 2 weeks. But the most important is to find the correct steel material. Today's result has encouraged me. I suppose making good staffs will be possible with our Schaublin. Is there other better possibility? Yes. Sliding axis lathes. These machines have 2 spindles. They start to machine the first side of the part, then the part is automatically transfered to the second spindle and the other side is machined. The part is completelly finished. I have two machines like this but they are for bigger diameters. Please visit this site: www.tornos.ch Then click Products - Single Spindle - Micros - Micro 8. Enter to Micro 8. The right machine is this one. Click the pdf file CATALOGUE MICRO 8 and see parts done with this machine. You will be surprised. Today I called TORNOS and asked for an offer. I will receive it very soon. They informed me that they have from this machine in stock. I suppose the value is around $200.000 We will see. If I can find another application for this machine, I can buy it. Now I need your assistance. I must to do a feasibility. How many staffs I can sell in one year? This is very important. I can buy the machine with 36 months leasing. Thank you in advance. Bulent  | ||||

|

I am sorry for the mistake. Steel used is not 1.2200 but 1.2210 Bulent | ||||

|

Bluent, I have what they call staff wire. They are short rods that were sold to cut staffs from. Do you think if I sent you a couple, it would help you identify the steel that was used? Brian C. | ||||

|

Brian, What is the diameter and the lenght of this wire. From the sample we can't identify the steel origin but if this is the correct material we can buy from this source. Again I will be happy if you can send me a sample from this wire. I will place you soon an order. I asked you some questions to you by your mail info@ptpwp.com. I am waiting for your comments for to finalize my order. You can forward wire sample with this order. Thank you very much. Bulent | ||||

|

Bulent, Just click on my e-mail address and don't add the info part. Brian C. | ||||

|

| IHC Member 376 Watchmaker |

Bulent i will send you some dia.s tonight for the hard too find model 1857 staffs ,,I could send a staff too you if you have luck making staffs that way you can have the staff in hand.. | |||

|

| IHC Life Member |

Bulent, You asked how many staffs you could sell in a year. That is a very tough question indeed and I have not a clue. However, I believe if you are able to take someone's old broken staff and replicate it, you would have a far greater audience. It is obviously more cost effective to set up for a particular staff and make x number of them, but there are many (especially European) that would need to be custom made. If I'm not mistaken, the setup time is probably more costly than the actual fabrication of the part. My honest opinion is unless you already have the machining capability, it would be extremely difficult to recoup an investment in tooling. Of course if the machine can perform other necessary tasks for your business, then that enters into the equation. ROI is a very difficult thing to calculate!! Roger | |||

|

Greetings, another way to manufacture the balance staffs is using a pre formed fine diamond wheel and plunge grinding the o.d. to the right dims. useing an external grinder with c.n.c capabilities. the proper stock to use would be pre hardened blanks of A2 air hardened tool steel with a rockwell of 56 to 58 on the c scale. A2 tool steel has high shock applications because of the chrome content of the steel also purchaseing the blanks would give you a guaranted rockwell tolerance. | ||||

|

| Powered by Social Strata | Page 1 2 |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide