| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Stainless Steel Waltham Mainsprings

Stainless Steel Waltham Mainsprings

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Stainless Steel Waltham Mainsprings

Stainless Steel Waltham MainspringsGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Has anyone else run into this problem. I put a new stainless steel mainspring in a Waltham 16s. The mainspring had a back curve starting about 4 inches before the end (hole end). When I wind up the watch I hear the spring slip. What I think is going on is as the spring is pulled to the center of the barrel by the arbor, the back curl is causing the hole end to lift off of the hook on the barrel. I tried to reshape the last 4 inches of the spring but I just broke the spring. What to do? Thanks | |||

|

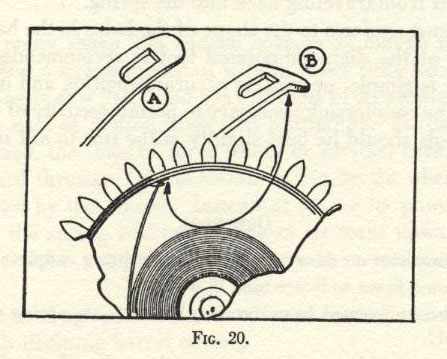

Yes, not too long ago and I believe it was also on a 16s Waltham. I looked in Henry Fried's book and found this drawing. Bending the tip of the mainspring like this seemed to have solved the problem.  | ||||

|

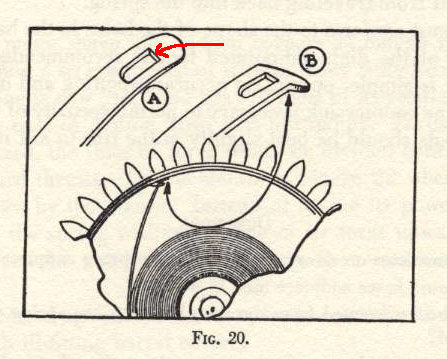

Filing a knife edge on the hole end also helps. Brian C. | ||||

|

On this inside edge, Brian? Is this something that you would routinely do, or just if you run into this problem?  | ||||

|

| IHC Member 376 Watchmaker |

Mark getting these stainless springs to work is sometimes a job on the hole end wathams,,ever time i install one of these i take a mainspring punch and make the hole just a bit bigger, a lot of the stainless springs will have too small a hole to go over the tab inside the mainspring barrel . | |||

|

I file the inside edge of the hole end. Brian C. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Stainless Steel Waltham Mainsprings

Stainless Steel Waltham Mainsprings

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Stainless Steel Waltham Mainsprings

Stainless Steel Waltham Mainsprings©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide