| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Handling History-- Hamilton SN-205

Handling History-- Hamilton SN-205

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Handling History-- Hamilton SN-205

Handling History-- Hamilton SN-205Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

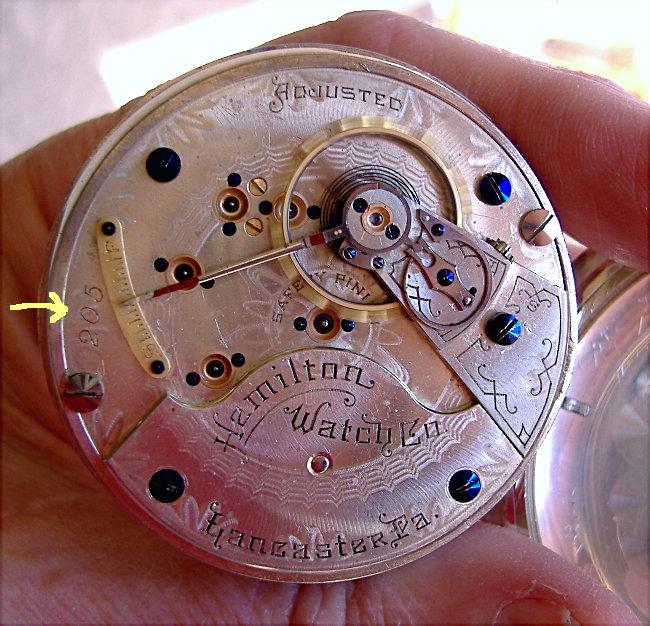

I bought Hamilton, serial number 205 recently. I also own SN-171 and I find myself awed by these early watches. I’m certain that there are not too many collectors who will not agree that these very early Hamiltons are historic. Restoring such a watch means making decisions. While I do not necessary buy-in to the philosophy that I am a mere steward for my watches (after all, I paid MY money), I have no less of an interest in preservation. That interest is balanced by my own sense of the aesthetic. I do my best! The movement was extremely dirty when it arrived. In tearing it down, I found gobs of liquid oil, mixed with gritty, black dirt. My theory is that someone wanted to put the movement into "running” condition and decided to oil the movement without cleaning. I noticed that you can buy oilers with long hypodermic needles for this purpose. It is a very egregious practice. The addition of oil turns honest dirt into a highly abrasive liquid mixture. I shudder that this historic watch could have been quickly ruined by running in this state. So… the decision to clean and oil was easy…. actually imperative. Other decisions would have to wait. I took a good long time dismantling this movement. Not only was I being careful but I was also savoring the experience of discovering the watch’s history and secrets. Every part that I exposed was stamped with the serial number of the watch and I was excited to learn that EVERY part matched. I found markings on the pillar plate, winding housing, top-plate, mainspring cover, balance cock and scratched onto the arms of the balance wheel. And… this is interesting… the pillar plate was stamped TWICE with part of one stamping obliterated by the milling of the plate to accommodate the drive wheels! Apparently, the watch is so early that the Hamilton employees did not know exactly where to stamp the serial number on the pillar plate. My understanding is that the serial number went on when the two plates were drilled for jewels… and before milling! Jewels were good and pivots were mostly fine… with the possible exception of one of the balance pivots which I thought looked a bit wrong to me. The movement was then cleaned and dried and set out on watch-paper for assembly. I made several decisions at that time. One was NOT to replace the mainspring. It looked good and NOS mainsprings are getting a bit rare. Second, I decided NOT to refresh the lettering of the watch. Under a loupe, I noticed that there was a shallow scratch across the serial number-205. I feared that this scratch would “take” the lettering paint. I was afraid that I’d spend considerable effort getting paint out of that scratch. The movement went together easily. This may be an historic watch but it’s not a complicated one. The top-plate DID fit very tight on the pillars and that can be a dangerous situation. If one puts too much pressure on the top-plate and inadvertently has a pivot out of the jewel… it is easy to break a pivot! For some reason, the pallet is usually the victim. I was VERY careful, pressuring the top plate in very small stages and checking pivots often. My efforts were successful and the train and power supply were all assembled. In setting the balance, I had some problems. The movement ran sluggishly and I wondered if my observations about a bent or peened pivot were correct. But, in the end I noticed that there was a large amount of endshake in the balance and concentrated on correcting that. The watch then ran, in all positions, with strong action. (Earlier, I timed it and obtained a single-line beat in every position but dial-up. Then it went to heck. I have not timed it since.) The movement has some very light speckling on the plates. I theorize that some solvent mist (probably ammonia) landed on the plates in the dark ages of its existence. Cleaning helped some but did not remove the marks. I decided NOT to use more aggressive techniques to clean the plates. I’ll leave it to some future technology to address that issue.  | |||

|

The watch came with a wonderful, clean double sunk dial! “Hamilton Watch Co” is signed in fine script which, I understand, is “proper” to this period. The dial was carefully cleaned and installed. Dial screws were found to be thoroughly boogered but I decided to leave them alone if they performed their task. Hands were proper and lovely “tulip” types… one of the most elegant designs I know. The minute hand has some discoloration and light rust and has obviously been fitted and refitted… a bit inexpertly. But… that’s what old watches have. The case was a thorny matter. That the lack of extra case-screw marks raised the POSSIBILITY that it was original to the movement. But… it looks quite horrid, with a thick brass ring, case-knife gouges etc. So to re-case this movement, I selected a huge, coin-silver 4oz case. The crown is well worn but that will be addressed in the future. The case had uneven tarnish, suggesting that someone had attempted to clean it… and failed. My decision was to take the case “all the way” to full polish, to enhance appearance and remove the clumsy previous attempt to polish it. Silver is quite stubborn to polish but it came out fine. The case had a thick and stunning crystal with a medium amount of age and scratches. NOS thick-crystals are difficult and expensive but I firmly believe that nice crystals are “windows” to our watches. They are also parts that were often replaced in a watch’s long history. I bit the bullet, got out the wallet and, with some searching, found an NOS thick crystal. The bezel has a screw-in crystal holding feature…. which is a whole other repair topic. Everything was now ready for the final assembly, right? Nope… at the end, I noticed that the lovely, massive case had no notch for the lever. I knew that a lever-notch could be cut but I’d never done one myself. In fact, I have shied away from the lathe but NEED to make friends with that tool. So… before this watch could be completed, I would need almost a day of learning. An old “junk” case was selected and I cut notch after notch into it, filing, squaring and polishing it. By the forth attempt, my technique had improved to the point where I was willing to risk my lovely case. I cut the notch into the case and was quite proud of the job. But… the lever bound-up. I was too timid and cut the notch too shallow. Back to the bench and I enlarged the notch twice as deep (I didn’t want to do it again). When finished, I polished the notch and then soaked the case in the ultra-sound to remove every bit of silver-dust. The case was then heat-dried to make certain that no moisture remained. The movement was cased without incident. The photos here are “down and dirty” ones with my mini-camera. I’m away from “home"and I will take better photos with better equipment. But, I did want the folks here to have an idea of how this historic watch proudly looks.  | ||||

|

| IHC Life Member |

Bravo! Beautiful watch and a wonderful post. Larry | |||

|

| IHC Life Member Site Moderator |

Peter, This amounts to an interesting write-up and history of early Hamilton, a tutorial on balancing common sense and restoration realities with preserving horological history, and also a model for us aspiring watch repair folks who are too chicken to work on important watches. So I definitely agree with Larry: Well done! Great post and even nicer watch!! IMHO, this is an example of what makes this Chapter so wonderful. I hope that someday my 7j Elgin practice project watch turns out half as well when I finally put it back together. John III | |||

|

Peter, I agree that is a great watch, great post about the restoration. | ||||

|

| Site Administrator IHC Life Member |

Peter, Wonderful story, however I respectfully disagree about being stewards of these masterpieces. Unless they are going to the great beyond with you I am certain you will pass them on. Just as you did the money you paid for them. Certainly better than being in the market right now. | |||

|

Philip: Before we needlessly disagree, I do think that we are in 100% agreement in our regard for these treasures and our desire to protect them for future generations. As you can see, I purposely did NOT attempt certain restorations that I thought were risky or destructive. For instance, any process of aggressively cleaning nickel-plate, by definition, would remove some of it. I decided to leave that to future generations and future technology. Our differences are, perhaps, philosophical. I guess I am a fierce capitalist and I believe that my ownership of the watch gives me the ultimate right to decide its fate. This right is superior to other opinions, personal or organizational. It certainly does not preclude me from being benevolent, knowledge-seeking, and protective about these items. I personally want this watch to survive for the enjoyment of future generations and regard that goal as superior to mere profit. But, I also contend that *I* own the watch and that ownership does not reside in an organizational consensus or in the hands of future generations, including my potential heirs! I realize and understand the contrary philosophy and the fact that our parent-organization apparently subscribes to it. I simply, respectfully disagree. | ||||

|

| IHC Life Member Sergeant at Arms |

Bully for you Peter Bully for you | |||

|

Peter, Very nice restoration.. I do have a question and maybe you can help.. It seems like very few Hamiltons had the blued screws, which I think is most attractive especially with the nickle.. Any opinons on when Hamilton used these colored screws, was it by, make, model, time frame ??? and why were they limited, because of cost?? | ||||

|

No idea at all John. My intro to vintage pocket-watches was from the side of watchmaking rather than collecting. I've certainly learned a lot in the 3 yrs that I've been around but I yield to others who have made a more thorough study of these things. From the point of view of a watchmaker, I spent a good deal of time examining this watch, as I noted. Because I found every numbered part to match and because of the general condition of the movement, I would assume that the blued-screws ARE original to his movement unless I learned otherwise. | ||||

|

Peter, I do think they are original also...In my opinion You just need to find 2 case screws to match.. | ||||

|

My guess is that it originally came with half-screws.... one of the worst ideas until Melamine! | ||||

|

Hamilton factory records show serial #205 as being originally sold on Feb. 21, 1894 to A.C. Hayes of Springfield, Massachusetts. I would assume that Hayes would have been the Hamilton distributor or dealer. As I understand it once a watch left the factory, it was SOLD... to the jobber or dealer. | ||||

|

| IHC Life Member |

Peter S/N 229 has nickel screws. This is a private Label Hamilton 932 that I am the proud processor of. I am including a photo of this pocket watch. What type of screws does your s/n 171 have. Thanks for any info you can supply. Doug | |||

|

Here's 171. Blues screws all around; even the hated half-screw!  | ||||

|

| IHC Life Member |

I find this interesting. Lindell has had this watch in his possession for repair on the dial. I believe the watch is original but cannot document so. Did Hamilton sell these watches according to customer specifications (ie blue screws, nickel screws) as they did to custom labeling. Or is it possible they used blue screws in normal production and nickel in PL watches ? I wish we knew the answers. Doug | |||

|

| IHC President Life Member |

Everything about your watch looked original to me Doug and I confirmed it as 16-Jewels as well. I found that all of the screws throughout the watch were polished. Perhaps as you speculated the fact of it being private labeled allowed that feature to be specified when it was ordered. Your guess is as good as mine, there is much we will never know for sure. | |||

|

| IHC Member 500 Wristwatch Expert |

My serial #28 (grade 932) has blued screws that certainly appear original. I just looked at pictures of numbers 2 and 3, which were manufactured on the same day as #28, and they have regular screws. But they are grade 936. My grade 936 s/n 760 has normal screws, yet a later grade 930, #19835, has blue screws. I'm as mystified as anyone.  | |||

|

| Site Administrator IHC Life Member |

Peter, I categorically defend your right to take a hammer to your watches or run over them with your car. We definitively agree, if you are the sole and exclusive owner of the watches in you possesion, it is no ones business as to thier disposal, organizational or otherwise. I just apperceive in your posts, you consider your watches,of more value, than the money spent on procurement. | |||

|

An of course then there are the "cheap' flat head blue scres..the dome top look much better.. | ||||

|

This thread certainly has a lot of "eye candy" as well as watch and life philosophy. I love this place...and those early Hamiltons, too. | ||||

|

| IHC President Life Member |

I agree... Peter did a wonderful job on the restoration and wrote an interesting, thought-provoking story. I get the impression all the 932 and 930 grades had blued screws originally. Number 595 is a 936 with polished dome screws... | |||

|

Phillip: Thanks for the clarification. I'd give my life for these watches but.... only because I wanted to, not because I was told too! I don't know why I'm so stubborn that way! | ||||

|

| IHC Member 163 |

So, the obvious question (well, at least obvious to this writer and type collector)....are you going to carry this beautiful watch? Regards! Mark | |||

|

Nope! Unlike yourself... some of my watches are consigned to just the collection. My habit has been to take a non-collectible watch and carry it. Then... over time, I tweak it to near-perfection for keeping time, and become so attached to it that I eventually upgrade it.... and.... have to stop carrying it! It's insane! | ||||

|

| IHC Member 163 |

No, actually I'm getting 'better' in that respect. I, too, have a few watches I take out every now and again to carry...but put back in the box to keep safe. I have some tried and true work horses that are built like tanks, though, that get pulled out on a regular basis, so I'm happy. Problem is, I expect them to ALL keep great time if they're in the carry rotation, so my obsession with that is as strong as yours. Regards! Michaelson | |||

|

| IHC Member 376 Watchmaker |

Peter nice watch you did a great job restoring it thanks for the pictures. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Handling History-- Hamilton SN-205

Handling History-- Hamilton SN-205

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Handling History-- Hamilton SN-205

Handling History-- Hamilton SN-205©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide