| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Waltham Vanguard balance staff

Waltham Vanguard balance staff

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Waltham Vanguard balance staff

Waltham Vanguard balance staffGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hello, i have a Waltham 16s Vanguard, serial number is 31245652 with broken balance staff, how i can find type/description and buy it? Fit with normaly balance staff of 16s Waltham? Thank you! | |||

|

These are friction staffs, used with detachable hub, not the usual riveted type. Two types of shoulder, straight (factory #4860) or tapered (factory #4861). Still generally available. | ||||

|

Many Thanks William, i try serch on the web. Fabrizio | ||||

|

| IHC Life Member |

Fabrizio, Send an e-mail with a photo of the broken staff to Brian Cavenaugh at; pwpartsetc@pwatch.com He should have one of these you can buy. | |||

|

Hello David!! I buyed today that balance on ebay item n° 300327413312 i think is the some of my, colored blue staff, from german seller. How i can remove broken staff? I read using only staking tool ( absolutly no lathe ) and put it again with staking tool again. Balance of Vanguard, how say William Thomas, is frictioned, i understand with pressure, no riveted. Correct? Thank you! | ||||

|

| IHC Life Member |

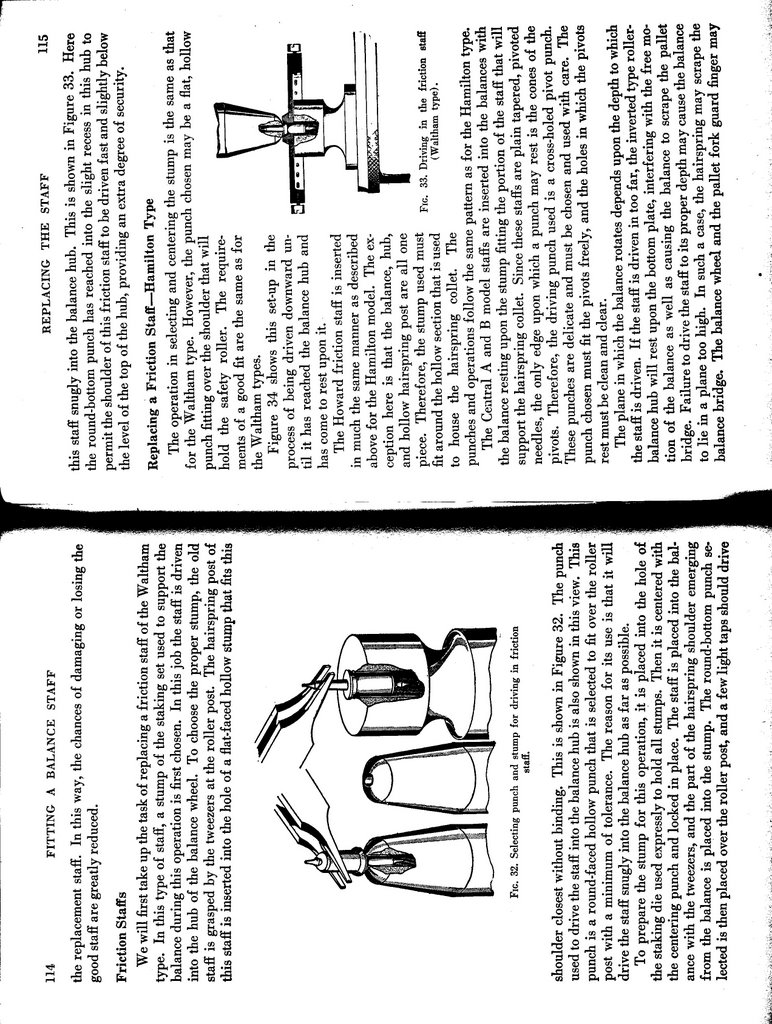

Fabrizio, This is copied from my first Edition Fried. I Hope it helps.  | |||

|

| IHC Life Member |

Other things to consider when replacing the staff: 1. Many staffs with the same number have several pivot sizes available. It is important to get the right size to match the jewel holes. 2. Install the staff by itself in the movement before putting it on the balance wheel to check for end shake and freedom of movement in the jewels. 3. After installing the staff, replace the roller table and poise the balance. 4. Install the hairspring and check for good balance motion in all positions. I like to see the balance oscillate for at least a full minute and come to a nice gradual stop with no jerking action. 5. Put the balance in beat by centering the roller jewel between the banking pins when the balance is at rest. This is done by rotating the hairspring on the staff at the collet. If you made a drawing of where everything was before you started and put it back in the same place you should be very close. If this were a riveted, rather than friction staff you would put the balance on a lathe and cut the rivet with a graver. Driving out the rivet without cutting first will ruin the hole in the balance arm. Roger | |||

|

COOL!!! Thank you very much David for book image and Roger for interesting info. | ||||

|

I removed broken balance staff, i have one taper sh #4861 but is not the some type of broken balance staff. Which is correct factory? Seems a modified balance staff. Thanks!     | ||||

|

| IHC Life Member |

As your Waltham is a 1942 production year Vanguard, it has the solid wheel and Elinvar Hairspring, so the new staff you got was correct. The new staff is a "Press fit Staff" which is installed into a Blued steel hub that is pressed into the Waltham wheel for that purpose. Your pictures of the broken staff you removed and the balance wheel you are trying to fix with the new staff show the last "service" to this watch was to crudely "revise" an old type "rivet" staff to "fit" in the wheel. But it is not clear that the Blued steel hub is still in the wheel. As the blued steel hub is required for fitment of the CORRECT new staff you have in the picture. I hope it is still in the wheel. If it is not, I suggest you contact Brian Cavenaugh at; pwpartsetc@pwatch.com for a used wheel you can take the hub from for this fix.  | |||

|

Thank you David! | ||||

|

Hello all! Finally i fixed it, thanks to David and William for help I put the balance staff on staking tool..    Old and new balance staff   Testing without cleaned the movement  Disassembly and cleaning   Final test! Working again  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide