| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Damaskeening

Damaskeening

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Damaskeening

DamaskeeningGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

In another thread I was asking whether or not the damakeening between the barrel and main plate was a perfect match. The reply was affirmative. I examined my 18 size Ball watches and was surprised to see that some do and some don't. Now the barrel bridge overlaps the main bridge, so the watch can't be damaskeened with the watch assembled. I really don't understand a lot about manufacturing techniques, but I suppose if the plates are done individually, it wouldn't be surprising to see slight offsets in the patterns. Frankly I am surprised by how many seem perfect! Not a really important subject, but its a quiet Sunday, so I thought I would bring it up. happy hunting, Bill Kapp | |||

|

| IHC Life Member |

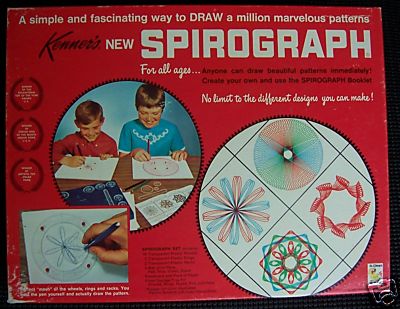

The Damaskeening machines must have (in my mind) resembled mechanically at least a toy in the 1960's that you could "program" to do an unlimited variety of circular patterns by adjusting and changins gears and arm lengths, etc. It was called "spirograph". On that toy, the patterns would repeat on any surface interrupted or uninterrupted. So to make Watch plates "match", (Waltham was a master at this) their placement registration when mounted for damaskeening had only to register to the proper angle around the movement they would be assembled to.  | |||

|

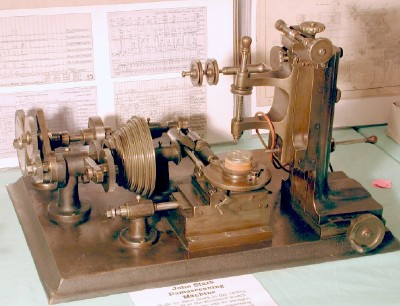

This is a really good look at a couple of damaskeening machines. The lower one was made in the 1870's for the Rockford Watch Co. by John Stark. Neat! http://www.awco.org/seminar2002/Machinery/damaskeeningmachines.htm Sheila  | ||||

|

Sheila, Thank you, that is a stunning post. I had no idea what this machine would look like. Reading the text, even I almost comprehend its function. happy hunting, bill Kapp | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide