| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Casemaking question

Casemaking question

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Horological Discussions, Questions and Answers

Horological Discussions, Questions and Answers  Pocket Watch Discussions

Pocket Watch Discussions  Casemaking question

Casemaking questionGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

In an earlier post someone of our members showed a selfmade watch-case housing one of thouse 'homeless' movements. It would be a great help if you recognize the person or remember the post and link it up ! And a happy new year to all of us. Thank's Gerald | |||

|

| IHC Member 179 E. Howard Expert |

Gerald, that could be me, I have made a few cases out of brass and aluminum. They are nothing fancy, since I don't use any high tech equipment... A small 7X12 Chinese lathe, Dremel, small drill press, a few hand held gravers, files, digital 4" calipers and lots of patience! I've made some wristwatches and pocketwatch cases. One of my first attempts was this rather rare Amn grade 17 jewel 8size Waltham, circa 1875. It is rather thick, I have done a Philadelphia Watch Co. KW/KS, and a few English fusees. Harold  | |||

|

| IHC Member 179 E. Howard Expert |

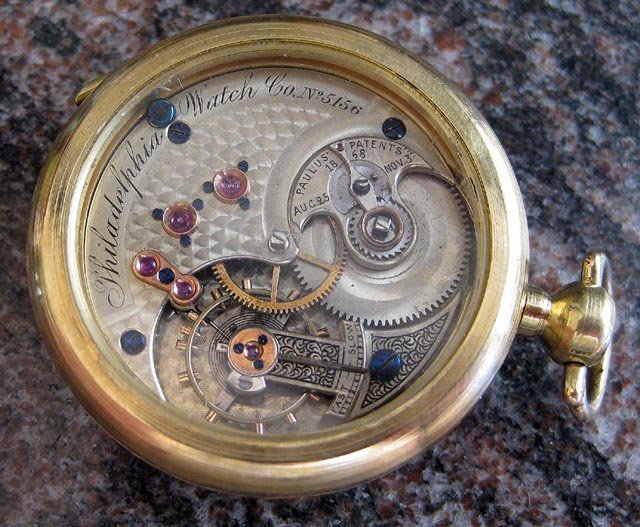

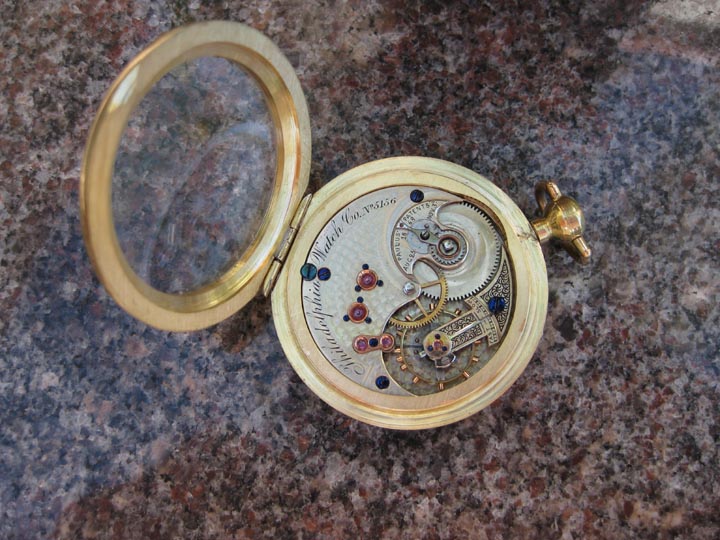

Here is the Philadelphia, the hinges were quite a project, lots of trial and error... Harold  | |||

|

Harold Thank You That was exact what I was looking for. With your name I can search the former posts. Great work that brought some beautiful movements back to life ! And for the equipment: What equipment had the real watchmakers of the past? I like this 'low-tech' 'high skill' way of doing. That gives me enough 'brain-food' for some long and cold winter evenings. Regards, Gerald | ||||

|

| IHC Member 179 E. Howard Expert |

Some more detail of what it takes, I purchased a 1 ft. length of 2 1/4" dia. brass for the pocket watch cases and a 1 3/4" dia. piece for wrist watch cases. I then slice off 3 or 4 1/4" pieces, and using a whole saw bit drill a 1" hole thru the center. The rest is measuring and lathe work. The hinges are made by using 1/16" brass tubing and steel rod that is a snug fit. To make the groove for the hinge, a 1/16" drill bit is chucked up in the lathe so only a small bit of it protrudes, then I remove the cutting tool holder using various thicknesses of plastic to get the height right for the groove, clamp down the case and using the crosslide go back and forth to make the hinge groove just about the depth of the hinge tubing diameter. The tubing is cut into three lenghts, two for the case body and one for the lid. I use a tiny bit of high temp grease to keep the solder from flowing where it's not supposed to as I set all three pieces in place with the steel rod to make sure everything is lined up properly. The first soldering attempt had all three pieces locked together...another tricky learning curve is to make the reverse taper so the lid snaps on snugly; let me tell you, many hours will disappear while hunched over the lathe... Harold  | |||

|

Beautiful work Harold. | ||||

|

| IHC Life Member |

Harold that is some magnificent work! After admiring the Philadelphia, I checked the price guide and see that it considered less valuable than some of the "higher end" dollar watches. As I see that watch work closer in value to a Patek Phillipe, I must be missing something. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide