| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Ball Waltham Motor Barrel

Ball Waltham Motor Barrel

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Ball Waltham Motor Barrel

Ball Waltham Motor BarrelGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 234 |

...have just acquired a 16S Ball-Waltham 19J RR Standard pw and can't for the life of me (altho' I wouldn't/shouldn't put that price on the effort) open the motor barrel on the piece to get at what I believe is a broken or slipping mainspring...am currently soaking it in penetrating oil hoping the lower pivot on the m'spring arbor will release...is there a trick to opening the barrel on this model?...what am I missing here?...thanks... | ||

|

| IHC Life Member RR Watch Expert |

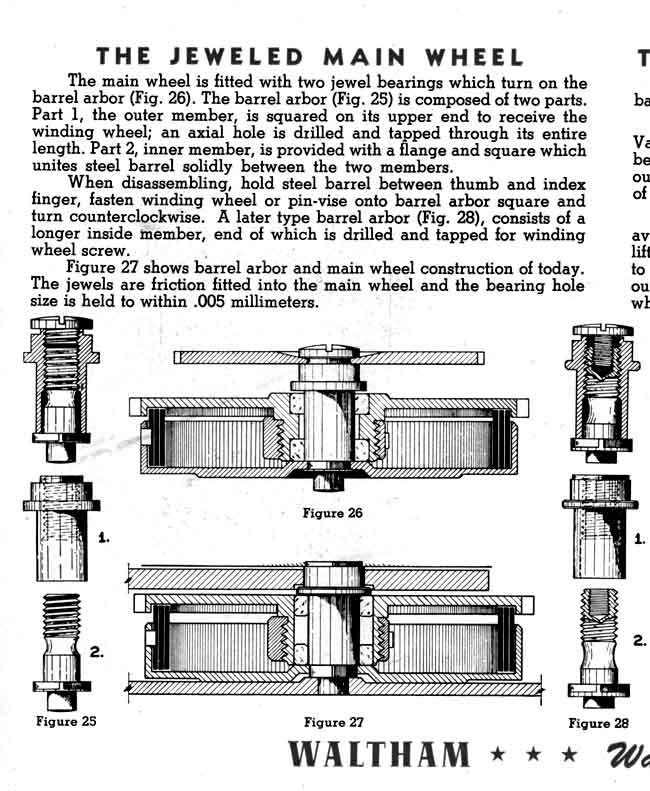

Jim, Assuming that the Waltham Ball has a jeweled barrel (that is NO cap jewels on either the pallet or escape wheel), here is the method I use to open the barrel for mainspring replacement or cleaning. 1. With the barrel removed from the movement, reattach the winding wheel onto the arbor square and secure it to the arbor with its screw. 2.Get a wide (1/8" or wider) rubber band, and wrap it around the smooth part of the barrel. It should not be wrapped over the main wheel teeth. 3. Holding the rubber band tight against the barrel with your left hand, rotate the winding wheel counterclockwise with your right hand. The bottom pivot of the jewelled barrel screws into the arbor from the bottom. Normal winding tightenes this threaded pivot and it can take a bit of force to break free. However, once it does, it should unscrew rather easily. Remember, the arbor has two parts, in addition to the barrel and the main wheel. To reassemble the barrel, place the lower pivot into the barrel so that the pivot is seated in the square hole in the barrel. Then, holding the lower pivot firmly in the barrel square, screw the top part of the arbor onto the lower pivot. I find its easier to keep the winding wheel attached to the top arbor piece as you do this, then remove the wheel just prior to putting the barrel assembly back into the movement. Ed Ueberall IHC Member 34 The Escapement | |||

|

| IHC Member 234 |

...Ed...thank you so much...it worked...I placed the bottom of the barrel in my bergeon bench vise and after attaching the winding wheel rotated it counterclockwise and it loosened/unscrewed!!!...Eureka!!!my first encounter (obviously) with a two piece arbor...again thank you so much for your help!!! Jim IHC#234 | |||

|

About a year ago, I bought a Waltham Model 92, grade 845 at an antique store. The watch had a broken mainspring. I had never changed a mainspring in a model 92 before. As was stated above by Jim, it gave me fits when I couldn't get it apart. Knowing it was not a common barrel, I didn't want to force anything. I took it into my watchmaker buddy at his jewelry store, and he showed me how to disassemble the barrel. He did it exactly like Ed described above. Oh Ed, how I could have used this info a year ago. Now I know to watch out for these rascals. Tom | ||||

|

The Waltham jeweled mainwheel (not a jeweled barrel) is nicely illustrated in the Waltham Watchmaker's Handbook.  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide