| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  Gilbert Question

Gilbert Question

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  Gilbert Question

Gilbert QuestionGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

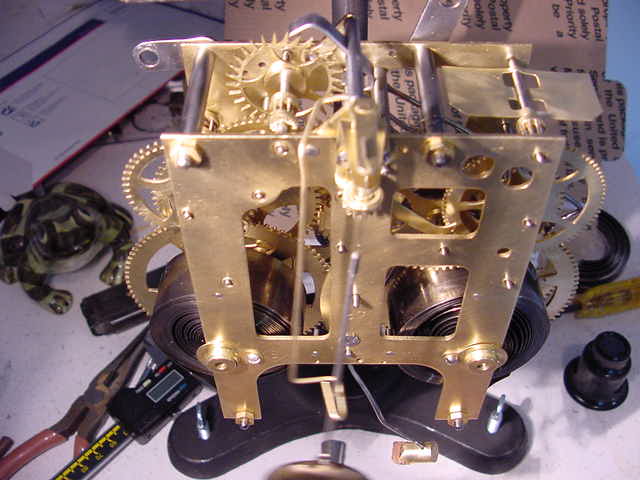

| IHC Member 376 Watchmaker |

I have a Gilbert # 27 movement that refuses to run.. have a couple of questions mainly about the Mainspring and the suspension spring...Do i need to replace the mainspring ,,do these springs loose their power after a movement has set for a long peroid of time not running.. I took the escape wheel out and let the train run it is free and i dont see any bad gears...The clock may run 2 hours sometimes it will run 24 hours then quite.. You will see in one of the pictures of the suspension spring someone has made 3 punch marks in the sping to keEp it from falling out..there was a short piece of the spring in the bottom of the clock case... Should i replace the suspension spring and how to i know what the right length is.. Thanks SAMIE  | ||

|

| IHC Member 376 Watchmaker |

2  | |||

|

| IHC Member 376 Watchmaker |

3  | |||

|

| IHC Member 376 Watchmaker |

4  | |||

|

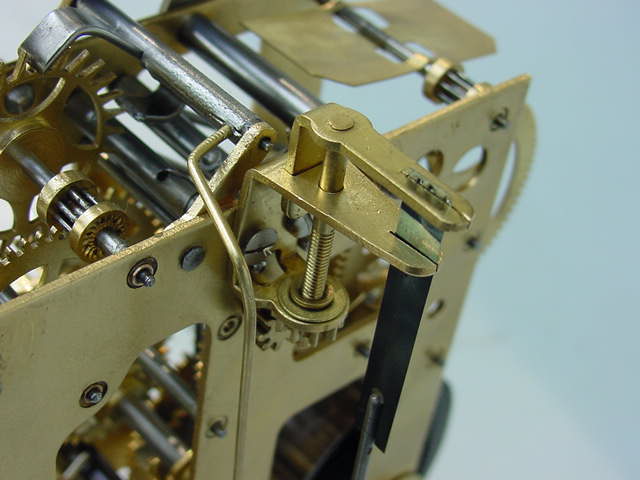

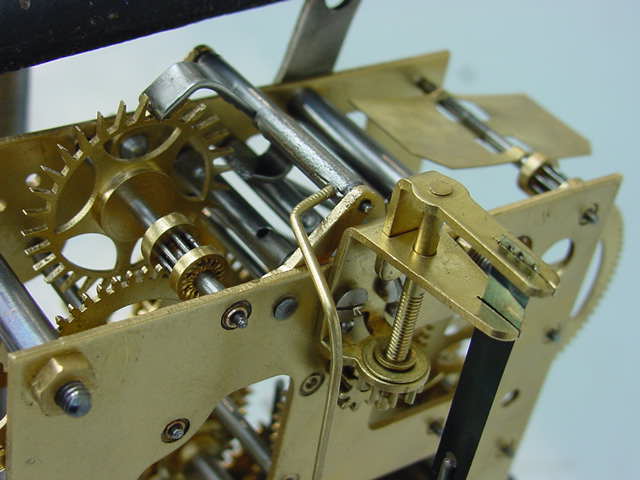

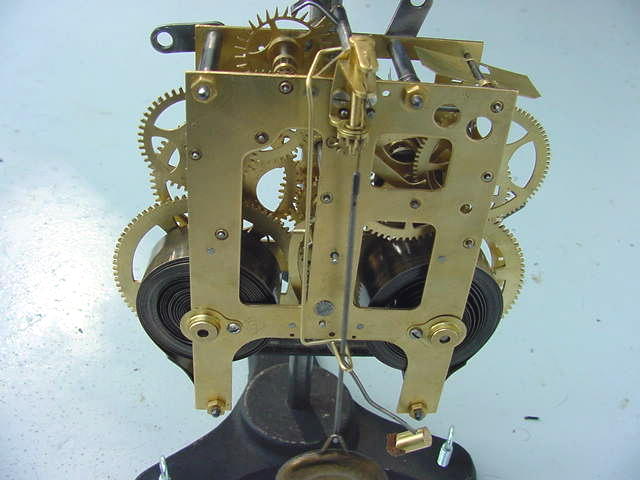

Samie,I know pictures can be deceiving but your crutch assembly looks crooked as **** to me at the point where the suspension rod enters it.That loop has to be perpendicular to the face of the plate both ways(90 degrees each way).You also want minimal clearance where the rod enters the crutch with the rod centered in the hole front to back.Your locks look a little deep also but maybe that was the position of the movement when you photographed it,if not that I would level that movement up and check out your locks to see if they are equal. As far as your suspension spring goes it is my own humble opinion that it has been altered.Perhaps the previous owner installed a new spring to replace the broken one and put that trio of punch marks in there,who knows.See if the end looks rough to you indictating a broken end.Usually there is a very small hole with a pc. of wire looped through it or a light prick punch indentation at the top of the spring to retain it in the chops.Personally I've never seen a suspension spring with three indentations,kind of overkill to me.If you saved that small pc.you found measure it and add that distance to your existing spring then take that total and whip yourself up a new assembly.If the broken pc was substancial a new spring may make a big difference.Yes,mainsprings can take a set if the clock has been sitting for eons but all that being said if you cleaned and lubed your mainsprings you still should be able to get more than 24 hours out of a full wind.You did give it a full wind,didn't you? Best of luck solving your problem. Respectfully,Bob Fullerton | ||||

|

The suspension spring looks fine to me and should run okay with it. The problem appears to be that the verge is running to deep in the escape wheel teeth. The arms holding the verge assembly are riveted to the front and back plate. They can be moved forward or backword with some pressure applied. I use a pair of duck billed pliers for the purpose. Reduce the depth until you get no more than about 1/8 inch drop on the teeth, then adjust the beat, wind the spring tighter than it is in the photo and it should work fine. It also appears that the loop in the crutch is to tight around the pendulum rod. Open it up so you can see some light between the loop and the rod. | ||||

|

All good advise written above. I would add that when adjusting the loop in the crutch, that too tight will bind, and too loose will cause a slap that robs power. It needs to be free, but not sloppy. My mentor has taught me to put a drop of PML Stem Grease on the loop. This has worked well for me for many years. If the drops are wrong, then you need to determine which drop is off. The inside and outside drops are adjusted differently. Have you checked for worn pivot holes and the need for bushings? Tom | ||||

|

| IHC Member 376 Watchmaker |

Thanks everone for the information ,,i tried some of the things mentioned and will see how it does.. When i cleaned the movement i lubed the mainspring good but did notice that it didn,t seem to be as srong as the one on the strike side .. i had to put bushings (8 of them) in the movement .. The verge was running deep into the escape wheel that may have been a big part of my trouble also the loop was loose and had about 1/8 in. space on each side of the pendulum rod..in the picture the loop apperars to be tight ,but it was very loose.. Thanks everone very nice of you folks to help a greenhorn out.. | |||

|

I saw immediately what DOUG saw. The verge too deep into the escape wheel. Now you said it does run so it certainly doesn't need lifted much because you want maximum impulse from the escape wheel. If you lift that verge away from the scapewheel only a gnat's hair or so, you'll be good to go. Also, a little on the picky side but you did ask. The loop in the crutch looks a little "VEE" shaped. Perhaps there'd be too much slop at the rear and perhaps it would interfere at the front. I try to get the crutch opening as parallel as possible with again- only a frog hair of clearance. Howard S. McElroy | ||||

|

Sammie, Often, with those movements, the crutch will become loose in the verge arbor. The top end of the crutch will then rotate in the arbor every time the verge rocks, putting less power to the suspension wire. Normally the end of the crutch is peened to secure it in the verge arbor. With the end of the crutch loose in the verge arbor, it will be almost impossible to keep the clock in beat. Just another thing to check. Best Regards, Dick Feldman | ||||

|

| IHC Member 376 Watchmaker |

Thanks everone for your help and advice ..I tried some of the adjustments and they did help..the clock still was stopping ,,looking back at the posts i remembered someone asked if the clock was stopping at the same time when it quit so i marked the tooth on the escape wheel where the verge was when it quit ..the next time it quit it was on the same tooth ..So i checked the wheel that drives the esacpe and there was 3 teeth that were flat on top not rounded like the rest,,didn,t look like it would be enough to make a difference ((BUT)) after rounding the the top of the teeth with a jewelers file my problem was solved .. Thanks everone for your help and with putting up with a amateur that still has a lot to learn. | |||

|

Good for you Samie....... Respectfully,Bob Fullerton | ||||

|

Good work Samie. good clock repair demands good detective work!! (Insert high five here!) Tom | ||||

|

HEY! If ya get worn out on clocks you could always go into periodontics! Nice job. Congrats! Scottie. Howard S. McElroy | ||||

|

| IHC Life Member Moderator |

The suggestions here were very good and helped me to understand some of the problems I also encountered during repair. I have my own German grandfather movement that sometimes stops at the same place. It seems to lock up with the striking mechanism. So I'll put it on the repair holder and start doing the same detective work. Thanks to all that contribute so generously! Moses Gingerich Waxhaw NC | |||

|

Your detective work is well in order but as you have already suspected - the problem with yours is more likely related to striking than to escapement. What does it do - stop right at warning or about 5 to 8 min. to the hour? You'll be looking for the load or resistance encountered there most probably that stops it. Also a clock that is just minimally running - has something wrong with it - may stop at warning because that is the proverbial straw - the load it cannot run through. Howard S. McElroy | ||||

|

I agree with Howard. One thing to look for is the strike hammer. At the end of striking does it begin to lift again - just a bit? If it does, this will load the resistance of the hammer on the get ready and frequently will stop the clock. The strike train needs some free spin to get up enough speed to aid in lifting the hammer. Tom | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide