| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  1948 Seth Thomas Brookfield electric chime

1948 Seth Thomas Brookfield electric chime

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  1948 Seth Thomas Brookfield electric chime

1948 Seth Thomas Brookfield electric chimeGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

When I received this clock it ran fine and keeps good time but the chime did not work. Consequently, I cleaned the entire unit in my ultrasonic, (since this is a riveted plate movement), and the chime started working again as it should on the hour and half hour. However, it began to slow down and now chimes sometimes and sometimes not, to the point of quitting entirely again. I'm wondering if I have properly oiled the chime train. so far all I have oiled on the clock are all of the pivots. The chime spring has a provision for giving it a few winds in the event it does not chime. (As detailed in the instructions) It is wound fairly tight now as when I first started it after oiling. There is a "ratcheted tension disc" on the chime spring drive gear. Should that be lubricated? Dave Turner  | |||

|

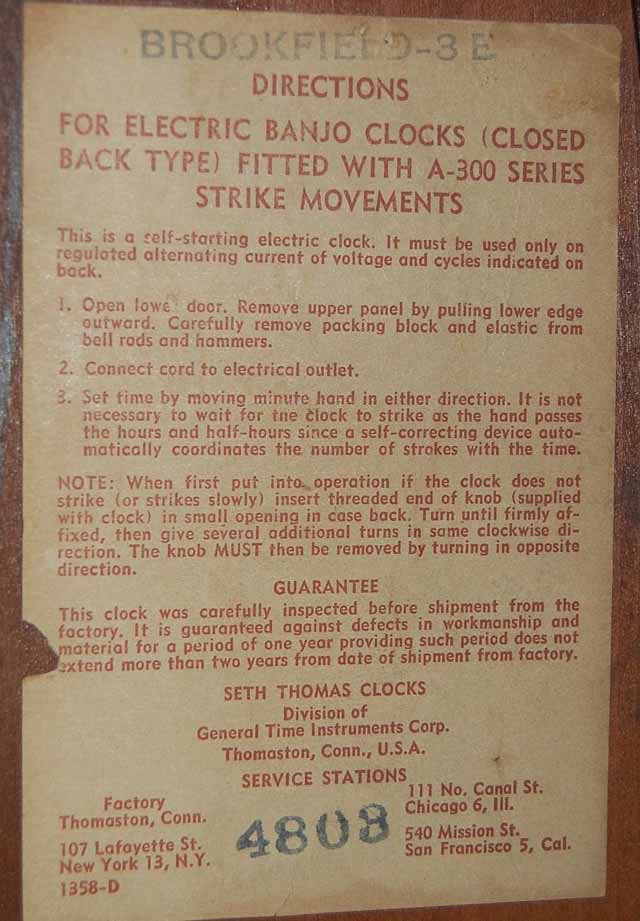

S. T. Brookfield Electric instructions Dave Turner  | ||||

|

No answers yet, but I'll give you a progress report. I have determined that the chime will work fine if I wind it manually for a short time until the spring starts to run down. So I now have the spring out of the clock but not sure how to remove the two gears on either side, (one drive gear and the other the winding gear). I'd like to open the barrel and inspect and hopefully replace the mainspring. Dave Turner  | ||||

|

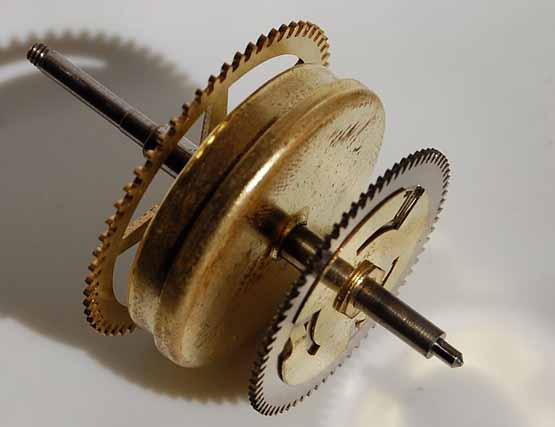

Spring from the drive gear side: Dave Turner  | ||||

|

| Life Member |

Unfortunately, working on these things is akin to working on an electric toaster. They are stamped sheet metal wonders. The Spring barrel is held onto the shaft by the brass washer on the wheel side. it takes some doing, but you can get the brass washer off, but then it will not fit tightly when you attempt to replace it. The only solution is to make a new one, that is a drive fit onto the shaft. Usually, the spring is not the problem with these Seth Thomas chime movements. Look for badly worn pivotsad holes in the sheet metal plates. hey are so thin that when they get dirt and grit embedded in them, they act like a saw. OFten you will find pivots with grooves in them that are nearly 1/2 the diameter of the pivot. The only solution is to cut the pivot off, drill out the end of the arbor, and fit a new pivot. I have tried bushing the plates of these, but they are pretty hard on bushing reamers, which are expensive. When I was running my repair business, I finally got to the point that I refused to work on them. It is difficult to explain to a customer why you have to charge two hours labor at $80.00 per hour, and $35.00 for a replacement Bergeon reamer for a clock that is only worth about $100.00 if in perfect running orfder. | |||

|

Thanks David, I did get that clock chiming without disassembly. And, fortunately it has been running steady and chiming correctly ever since. I agree, it's a cheap clock and not made to work on. But being electric it keeps good time and doesn't require winding. So, I'm lucky, I've already got my $35 back! Dave Turner | ||||

|

| Life Member |

When they are running right, those Seth Thomas electrics with the mechanical chime and strike are not bad inexpensive clocks. And I must admit, most I have seen were in what I would refer to as "high style" art deco cases. I had one for a long time that used to live on top of my 1938 floor model Philco, opposite a photo of Lena Horne from the same era. They made a nice combination together. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  1948 Seth Thomas Brookfield electric chime

1948 Seth Thomas Brookfield electric chime

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  1948 Seth Thomas Brookfield electric chime

1948 Seth Thomas Brookfield electric chime©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide