| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  Letting down a mainspring

Letting down a mainspring

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Clock Repair Questions and Answers

Clock Repair Questions and Answers  Letting down a mainspring

Letting down a mainspringGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

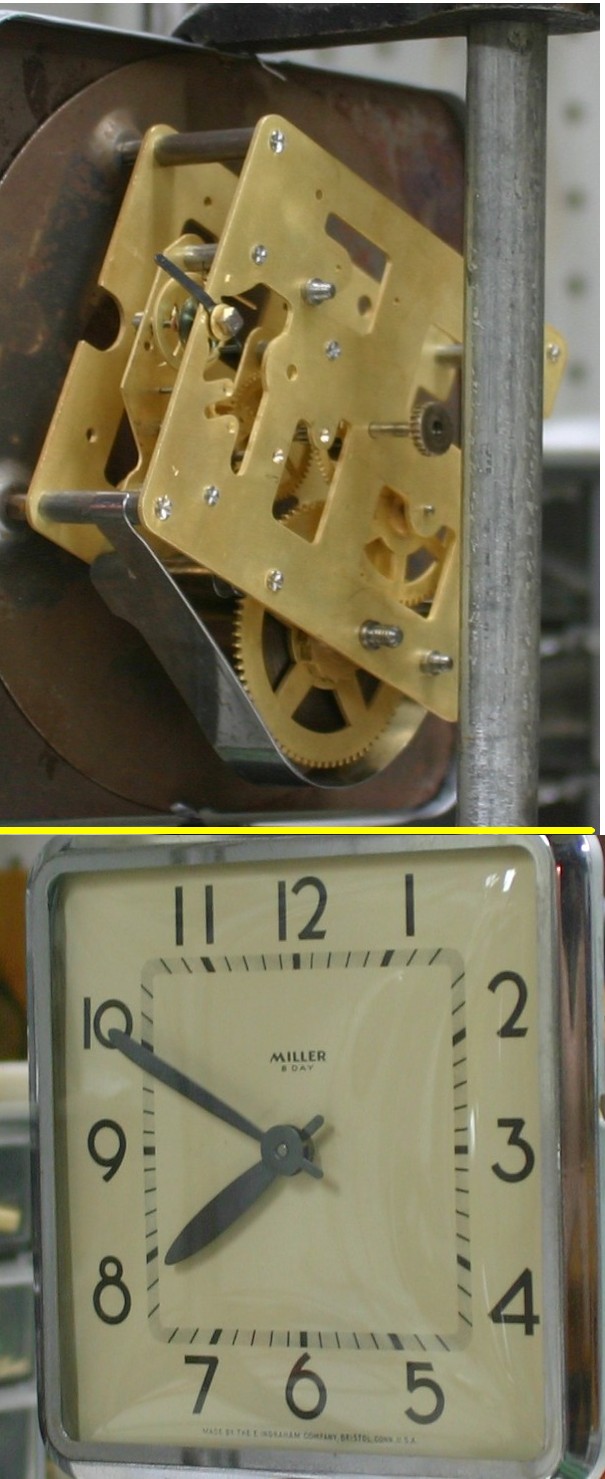

How does(other than carefully) one "let down" a mainspring such as the one shown. Greg  | |||

|

Hi Greg, is that the spring showing in the picture or the barrel? I thought if it is the spring showing you could contain it with c clamp. | ||||

|

Yes, it is the spring. The problem is not how to contain the spring, but how to let it down properly. Your right in that a small clamp or plastic tie will contain the spring. A response that I've received...is to take a "Let-Down Key" and cut a slot in the end(photo enclosed). Seems like a good idea...but will approch it carefully. This one for example is from an alarm clock. The arbor has a left hand thread. So to let it down it would turn to the right. I've tried pin vises, vises, with mixed results. The pin vises can work on smaller springs, which are not usually strong enough to do lot of damage to yourself, but can wreak havoc on their movements should they let loose. The larger springs are much too strong for a pin vise. I did try to hold the arbor in a lathe, but even this wasn't going to work this time. This tool may just do the trick. Thanks greg Greg  | ||||

|

Sounds like a good idea Greg, let me know how it goes. Thanks. | ||||

|

Greg: I just dealt with a Seth alarm and had the same problem. I used the threaded butterfly winder that was on the movement; however I slowly roted the movement and held the key stationary to let down the spring. It worked okay for me. good luck! gp Grant Perry | ||||

|

Hi Greg: Merritts sells a letdown key specifically made to fit over a clock key as opposed to the type that fit over the arbor.It looks like it will run you about $15.00,might be a good investment for your clock repair tool collection. On the subject of plastic ties I would tend to stay away from them if I were you.I used them for many years in heating and ventilation work and I can tell you from experience that they are susceptable to breakage,even the thicker ties.If that tie has one little fracture in it ,as soon as you apply tension to it you can rest assured that the tie is going to separate,maybe not immediately but it will,believe me.Stick with the mainspring clamps,they're a lot safer. I hope this is of some help to you Sincerely,Bob F. | ||||

|

I thought more about this and wouldn,t you normally just put a clamp on the spring and remove it out of the movement.Then let it down after. Maybe there is something i am not getting. I have also taken a dowel and cut a slot in it to fit over a key, to make it easier to let down a spring. I am sure i probaly have not helped much as i am a rookie on clocks. | ||||

|

Grant...I've done it that way before and again...mixed results. By this I mean that it worked great the first time! It just doesn't work every time, and unfortunatley you don't get a second chance with these less than rugged movements! On this one I had great success with putting it in a webster, and secured the movement against the bar that protrudes out of the winder. Of course I thought..ah ha! However once I cleaned and polished the arbor...I could not get the webster to hold. I knew that someone has had this problem before me...so I asked, rather than try to invent another wheel. Keven...one end of the spring attaches to one of the corner posts. The spring was almost fully wound. So to try and hold the spring, remove the nuts that hold the movement together, remove the gears is usually a bit too much for me. I've bent/broken gears and teeth(not mine, but close) and scared my self to death trying to repair these things. I'm always glad when I see one whose spring had been broken(before I got it)...just made life easier! But now I think that is all over with(hopefully!)? LOL Greg | ||||

|

I forgot Robert! Yes...I had one break on this one! Probably better for the smaller springs. This is actually an 8 day movement, but built like an alarm type movement. Made by E.Ingraham Greg  | ||||

|

I looked at the Let down keys and wondered about their versatility. Came up with my own idea(?)...a "hand vise"...that I found no other use for!! It works really well!!! Thanks for all of the help! greg | ||||

|

The clamps are best to maintain the mainspring but if you don`t have a clamp a piece of strong binding wire around the middle circumference, twisted or crimped down snug works well on the wider mainsprings. Kenny | ||||

|

Greg since one end of the spring is attached to a post, how did you remove the spring, and did you let the power down with the spring in the movement? I have a similar movement and wondering how to contain and remove spring. | ||||

|

Good Afternoon Kevin, trouble with our isp has delayed in the answer to your question. While in the movement...I wound the mainspring up, secure the mainspring with wire(around the post, let the mainspring down(I used the hand vise and key), remove one of the plates(I also remove as many gears as I lift the plate), remove the rest of the gears and then the mainsprings. Place the mainspring in a "winder" and you should have it from there. greg | ||||

|

Thanks Greg, for the answer, no problem in the delay in answering. I would like sometime, not sure when to work on some alarm clock type movements. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide