| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Dial Printing Machine

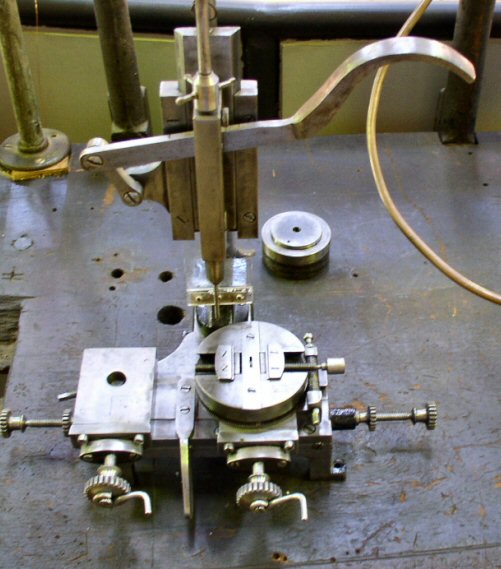

Dial Printing Machine

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Dial Printing Machine

Dial Printing MachineGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Copper dial plates are first fired with white enamel then placed on this machineto be printed. First,enamel of the desired color is placed on the engraved master dial plate, the excess removed with a straight edge, the overhead spindle with rubber-like pad at end is lowered and pressed on the master dial thereby picking up the wet enamel from the engraved master dial,next the sliding table that holds the master dial and the blank dial moved to the appropriate position so spindle can be lowered to print dial. This method was faster and much cheaper than hand painted dials. George Collard Frank Menez Trustee CRMI | |||

|

| IHC Life Member South-Bend |

There's some more interesting technical information from a 1910 article at: http://www.southbendhorology.com/machinery/m18.jpg http://www.southbendhorology.com/machinery/m19.jpg Best regards, Frank "407" Kusumoto | |||

|

Frank- - --- Great reading and very enlightening. - Frank- Frank | ||||

|

| IHC Life Member South-Bend |

Frank, Glad you enjoyed it! Thanks to Frank for posting the original article which made me think of it. -Frank | |||

|

This machine is on display at the CRMI.  | ||||

|

Another part of the machinel  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide