| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Screw driver tips

Screw driver tips

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Screw driver tips

Screw driver tipsGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

I have always thought that English gun makers had the best idea as to "turn screw" tips. The tips were made to fit a certain size screw. The tips were ground with a radius so the tip rested on the bottom of the screw slot. That is where the pressure is applied when force is exerted turning the screw. This resulted in less slippage and way less buggered screw heads. | |||

|

Sorry for the size of the pic. I reduced it as much as I could. | ||||

|

| IHC Life Member Certified Watchmaker |

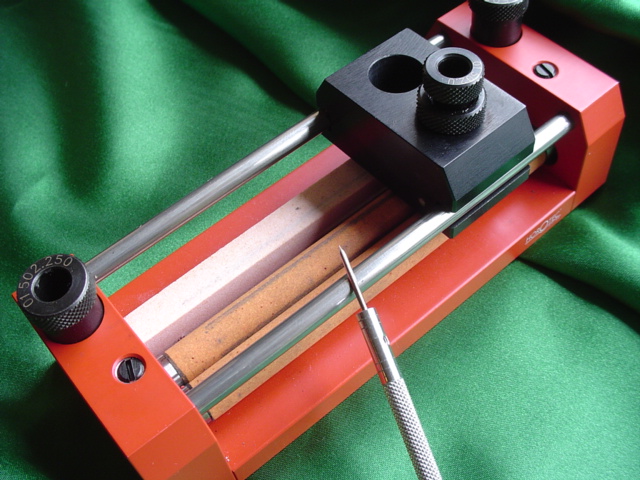

Ed, Your spot on there. Here is a tool I use to shape the drivers to prevent maring the screw heads.  | |||

|

| IHC Life Member Certified Watchmaker |

close up of tip after  | |||

|

That is a neat sharpening jig Chris. Manual operated, for more control. Holds drive at a 90 degree angle, changeable collett holder. Do all watchmakers sharpen for a radius? | ||||

|

| IHC Life Member Certified Watchmaker |

I don’t think they are commonly used. I invest heavily in upgrading my tools & equipment. Next month I am trying to arrange for the re calibration of my timing machine by the manufacturers, and following month I have my eyes on a top of the range case back machine, and so on my list is endless I love nice tools. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide