| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Staff Tool

Staff Tool

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Horological Tools, Books and Miscellaneous

Horological Tools, Books and Miscellaneous  Staff Tool

Staff ToolGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 234 |

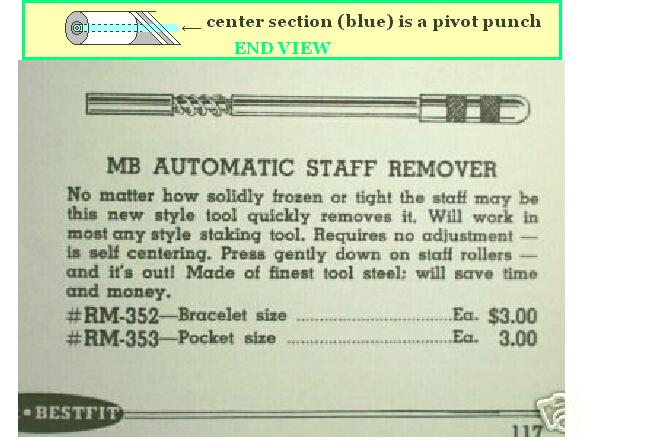

...am wondering just how effective this tool is at opening the staff rivetting and freeing the broken staff from the wheel as advertised: "fits over the staff and opens the rivet"...sorry for the poor pic quality, I pinched the image from the net and was only able to double the image's size w/o distorting it beyong recognition...  | ||

|

Jim i am curious about this tool also, Kenny i believe has a few of these and has experience with them. I would like to get the pw size and give it a go. I have seen them go relatively cheap to fairly expensive on Ebay and elsewhere. | ||||

|

It is difficult to tell from the picture, but if this is a type of punch for knocking the staff out of the balance wheel, it is a very poor choice of tools. The best way to remove a staff, with the least damage to the wheel, is to turn the hub off of the staff in the lathe and push the staff back out from the bottom. If you aren't comfortable with the lathe and must use a punch, use the K&D punch in the staking set that comes with a clamp-like device which holds the arms of the balance perfectly flat and snug against the anvil so that they will not get distorted. Even with extreme care, using a punch to remove a staff can enlarge the hole in the balance arm so that a replacement staff may no longer fit snugly. Punches like this also will not work with a balance wheel that has the arms mid-height in the wheel rather than at the bottom. If the tool above really does somehow open the rivet, I would be curious about how it works. | ||||

|

| IHC Life Member |

Jerry describes the preferred way of removing a staff by cutting the hub. The only exception that I can think of is the Waltham model 1857. One of the staffs used on this model is all hub except for the pivots. For this staff, you must cut the riveted area and gently tap the staff out through the bottom of the balance arm. Some 18s Elgin staffs have a long hub which requires a lot of cutting to remove the hub and I prefer to cut the rivet on these. Extreme caution is in order not to damage the balance arm. Even then, you still risk the chance of opening the hole while tapping the staff out. This is due to the balance seat of the staff being deformed into a conical shape during the previous riveting process. Also, take Jerry's advice about using a staff remover. Personally, I would never use a balance remover except to tap a staff out that has the riveted area already cut. Some staffs were riveted so well, that the rivet doesn't shear very easily and severe damage can occur to the balance arm. The tool in question is very interesting. My first thought was that it had a cutting edge similar to a balance screw undercutter. You would slide it over the balance and cut the riveted area while the staff is turning in the lathe. | |||

|

| IHC Member 234 |

....this tool, it is said, is also "spring-loaded"...was just curious whether 'technology' had passed me by (again) and this tool was just as effective/efficient as removing the staff as the lathe method which I have been using...thanks fellas for your responses...think I will continue w/the 'tried-n-true' lathe approach... Jim IHC#234 | |||

|

I have used this type of staff remover exclusively since I don`t have a lathe. Though cutting out with a lathe seems to be the preferred and to some the only acceptable way to remove a staff, this method has worked quite well for me. The secret is to choose a tight "close-tolerance" stump or anvil hole (barely clearing the roller hub) and light hammer taps. The end of the tool fits over the exposed staff (hairspring or rivett end). Then I press the tool handle down with my hand until I meet resistance, then a few light hammer blows will extract the staff. The end of the tool exerts pressure on the balance arm securely pinning it to the anvil. The amount of pressure is relative to the force of the hammer blow. The strong spring allows sufficient pressure but provides some "give" so the arm isn`t peened. Again, I can only say it works for me and has in every instance I`ve removed a staff, without any visible or other detectable damage to the balance arm. The balance wheels all worked fine after restaffing. I`m sure you could botch it if you aren`t careful but you could also do a pretty good botch with a lathe. Kenny  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide