| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Model 1857 Balance Staff Info for Underspinger's

Model 1857 Balance Staff Info for Underspinger's

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Model 1857 Balance Staff Info for Underspinger's

Model 1857 Balance Staff Info for Underspinger'sGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

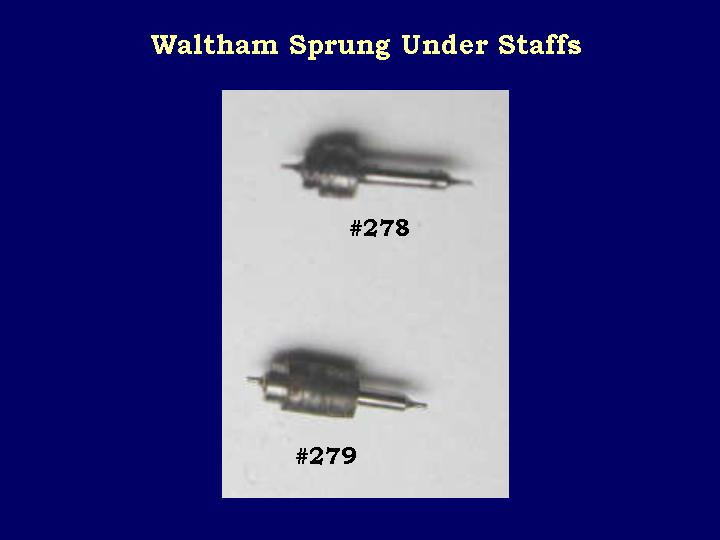

The following is information obtained from Swartchild's Build-Up System for genuine American balance staffs: "18s Waltham staffs, generally available on special order at factory" Series A - Sprung Under, factory #278 (in millimeters) Total Length - 5.60 Balance Seat - 1.25 Hairspring Seat - 1.25 Roller Seat - .61 Hub Thickness - 1.03 Series A - Sprung Under, factory #279 Total Length - 5.70 Balance Seat - 1.25 Hairspring Seat - 1.25 Roller Seat - .61 Hub Thickness - 2.14 It seems strange that the hairspring and balance seat dimensions are the same. Since the roller and hairspring are co-located under the balance wheel, one would think they share a common dimension. Other Series A staffs for the 1857 are sprung over types #277, 280 and 281. There is also Series B staffs which I believe are for the 1883 models. Can anyone validate this info with a Waltham materials catalog? John D. Duvall Vice President, Education  | ||

|

| Watch Repair Expert |

For all practical purposes, the 1857 model was Waltham's first attempt at a truly mass produced watch, and they remained in production for something on the order of 20 years (perhaps even longer in smaller quantities). Needless to say, the basic model "evolved" significantly over the years, and the balance was one of the main parts that changed. Not only did it change from year to year, but also from grade to grade, with "Appleton Tracy" models having different staffs than the cheaper "Home" series, etc. Even in the best of circumstances, if one found a staff that was really close to the original (as one or the other of the ones above may well be), it's almost certain that some "customization" will need to be performed in order to fit the staff into the watch, and make the watch run. A similar situation exists with early E. Howards, etc., when perfect parts interchangeability had not yet been achieved. A compounding problem is that years ago, when Swartchild and others attempted to supply "full line" staffs to fit ALL American watches, they often didn't have the original factory specifications, and were forced to copy staffs from existing watches, many of which were themselves hand made copies! Needless to say, after a duplication process has been performed numerous times, errors begin to creep in. It's like making a photocopy of a photocopy, or second and third generation copies of keys for locks. No copy is ever quite as good as the original, and sooner or later, the end result will be a substantial change. In any event, I'm glad to see someone making a good effort to help Brother Glyn! He certainly needs it in this particular case, and I know that it will be a good experience for all involved. If he's extremely lucky, one of the replacement staffs above will work with little modification. I never get that lucky myself, but some people do....... ========================= Steve Maddox Past President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Model 1857 Balance Staff Info for Underspinger's

Model 1857 Balance Staff Info for Underspinger's

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Model 1857 Balance Staff Info for Underspinger's

Model 1857 Balance Staff Info for Underspinger's©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide