| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  (found lost parts!!!) damaged Waltham pallet fork?

(found lost parts!!!) damaged Waltham pallet fork?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  (found lost parts!!!) damaged Waltham pallet fork?

(found lost parts!!!) damaged Waltham pallet fork?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

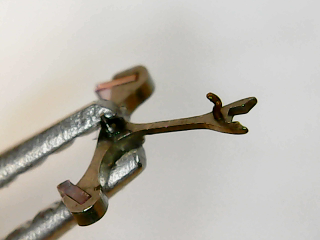

hi everybody, so i started on my second non running Waltham today. did my first Waltham this weekend and after cleaning and oiling it started right up, i love buying non runners. good for practice and good for my confidence when they start up. this one however may be a different story, there are a lot of scratches around the screws indicating a monkey tried to take it apart before i got it. as soon as i took out the pallet fork i saw a big problem, what i believe is called the guard pin, seems to have been bent out of shape. is it possible to fix this? is there a technique for fixing this or do i look for a replacement or parts watch? i have a lot of experience working with small tools and parts, (no smart comments please, this is a family friendly site) so i think it may be possible to put this right with patience and care. and what a victory it would be! thanks everyone Todd  | |||

|

| IHC Member 1736 |

Todd, I'm not so sure it is "out of shape"... this may be by design. Dry fit the balance assy and pallet, check the clearances of the guard pin and it's relationship to the notch in the roller plate. This pin should roll through the notch in the roller plate as the jewel passes through the tail of the pallet fork. Good eyes, lighting, visual angle... it can be a bear to see and is hard to focus on for any length of time. I have had some luck with lining everything up "static" taking a photo, then blowing up the photo on the computer. The pin will tolerate some "working", but the metal does work harden pretty fast... you only get a couple shots at it. | |||

|

Todd, Looks like the guard maybe ok. Some of the walthams have that curve in them. Don't adjust it. Clean the watch and see how it does first. Rob Www.pocketeatchrepairs.net | ||||

|

| IHC Member 1736 |

I have a "automobile dash mount" for my cell phone... Select the camera on my phone to macro... It works like a bench top tripod for the phone... I get great pictures and instant gratification on being able to view them and manipulate them right there on the phone. | |||

|

it is now a moot point, my grandson just came running in and knocked my parts tray onto the floor. can't find a couple of things. glad it wasn't valuable and that i have a sense of humor. from now on i lock the door when the grandkids are here. thanks everyone Todd | ||||

|

| IHC Member 229 |

I have found many MIA watch parts by "sweeping' the floor of my work area with a roll of magnetic strip available at most hardware stores. Roll out the strip flat on the floor...and...while holing one end sweep the floor. Good Luck..Tony C | |||

|

hi Tony, i thought of that, i have a magnetic broom i made from a bunch of old microwave magnets that i use to clean my garage floor of screws and other tire hazards. found everything except the pin from the winding mechanism and the pallet fork. the pallet fork was definitely damaged, when in place on the movement with the balance assembly, the guard pin was no where near the roller table. anyone have a size 0, model 1900 grade 110 parts movement for sale? Todd | ||||

|

| IHC Life Member |

hat Guard pin is by design made that way to avoid interference from nearby stuff. Clever idea. | |||

|

hi David, are you saying that was correct? the guard pin was so far away from the roller table that it could never contact it. at that distance it could not have possibly performed its' intended function. Todd | ||||

|

| IHC Member 1736 |

Todd, I think Dave is saying exactly that... I don't think the guard pin actually needs to go in to the slot... it just needs to align with the slot. If the guard pin is lined up, the roller jewel will be lined up, assuming it is straight and true. | |||

|

hi everybody!! i looked really close at my magnet broom just now and found the pallet fork and the pin from the winding mechanism!! they were stuck in a seam of the cover. tomorrow i will reassemble the pallet fork and balance wheel on the movement and use my digital microscope to take a good look at what is going on with that guard pin as it relates to the roller table notch. not thrilled that i found the parts as much as that i will get to analyse what is really going on with this crazy guard pin. and i guess i am goung to have to do some serious demagnetizing of this movement. Todd | ||||

|

Todd check out this video I think it will help you understand what a safety pin is suppose to do. https://youtu.be/DxeM85XRTbU Thx and good luck! Glenn | ||||

|

hi Glenn, that video demonstrates the problem i have with this safety, or guard pin. when i rotate the balance out of beat i can still move the pallet fork back and forth to each guard pin. that should not be possible if the pin was correct. as David pointed out that is the correct shape for this pin so perhaps i need to tweak it forward just a touch. todd | ||||

|

| IHC Member 1736 |

Todd, I learned to be gentle with the guard pin. They don't tolerate being pushed around much... I only get a couple shots before they work harden and snap off. As a rule, I don't mess with them unless the watch has a problem with overbanking and I've exhausted all other options. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  (found lost parts!!!) damaged Waltham pallet fork?

(found lost parts!!!) damaged Waltham pallet fork?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  (found lost parts!!!) damaged Waltham pallet fork?

(found lost parts!!!) damaged Waltham pallet fork?©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide