| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  1st watch cleaning experience...success...disaster...help

1st watch cleaning experience...success...disaster...help

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  1st watch cleaning experience...success...disaster...help

1st watch cleaning experience...success...disaster...helpGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Well, I finally got to the point where I felt confident enough to try my 1st cleaning. I had a 16s 15j Elgin pocket watch that I had purchased on ebay. It would run for a few seconds then stop. I managed to completely disassemble the whole thing, clean the parts in my L&R Master cleaning machine. re-grease and re-install the mainspring, peg out all the jewel holes, re-assemble the watch, and oil and lubricate it. The works were now spinning freely, winding and setting was working fine, and all that was left to do was to install the balance. I installed the balance and balance cock, but I was having a little trouble getting the hairspring into the pins of the regulator. I thought that I would remove the balance cock again so that I could get a better look at it. That's when the disaster struck... My dog, who had been quietly sleeping on the floor, woke up and saw a deer out the window in my side yard. My dog is a beagle who is just born to hunt and track. When he saw the deer, he suddenly jumped up, lunged at the window, and started barking loudly. Meanwhile, I was very carefully removing the balance cock with my tweezers. The house was very quiet, and the sudden movement and barking startled me. When I jumped, my hand twitched, and the balance cock and balance went flying. In looking through the Illustrated Manual of American Watch Movements book, it looks like the broken balance staff is Elgin #861. I do not have the tools or the ablilty to replace a broken balance staff, but after all the work that I did, I really want to see this watch tick. What would be the best way for me to get this fixed? I thought of going to a watch repair shop but I have the feeling that replacing a balance staff might be expensive? I was wondering if perhaps I should look for another broken watch on ebay (with a good balance)? The watch I am working on is an Elgin, 16s, 15j, open face, 3/4 plate, model 7, grade 313, 1918. When I looked this up on the Elgin web site, it says that the watch is Class 110. Within this class are grades 291, 293, 300, 313, 366, and 387. Will the balance from any of these grades work in my grade 313 watch, or do I need to look specifically for grade 313? Any suggestions where I can find a balance wheel with staff already attached? | |||

|

Tony, It sounds like you did a great job for your first cleaning effort. Just a suggestion, but perhaps you can set aside that watch until you gain more experience, then YOU can re-staff the balance yourself. In the meantime, hunt for another, similar watch on eBay or wherever, and have another go at it. Don't get too discouraged. You can read the thread I started about "A Bad Day Today..." Pete | ||||

|

Tony, congrats on taking the watch apart, and putting it back together.And oiling and greasing it. You had what we have all had, a bad watch day.There will be more of them in the future likely. I would go with what Peter said and get another watch to practice on.The part you need is probaly not hard to get, but i would save the watch with the broken staff as a project watch for later on. There was a practice watch going around IHC 185.I do not know what came of it.Perhaps if it is found you could practice on that one. I wish you the best of luck in our future watch work. | ||||

|

| IHC Life Member Watchmaker |

Fastest thing to do is find a parts watch, and take the balance complete out of it. I don't think you will have too hard of a time finding one. Keep the broken balance staff and later on you can try to make one, or even try to repivot it. | |||

|

Scott, that is exactly what I have been thinking. That way, I will end up with a working watch, plus I will still have the other watch and the broken staff to play with. When looking for a parts watch, will a balance from any class 110 watch fit?. Are the balances the same among all different grades in that class? (grades 291, 293, 300, 313, 366, and 387)? | ||||

|

Tony, They all used an 861 balance staff, however, they didn't all use the same balance wheel. The grades 291, 293, and 300 had a different balance on an 861 staff than the other grades. To further confuse the issue, Grades 313, 366, and 387 changed their balance wheels at SN 16,502,601. To find one compatible could be a crap shoot. Incidently, most "parts watches" usually have a common trait... broken balance staffs. Also, the movement SN is written on the underside of the balance arms. If you put in another balance, it will have a different SN than the movement. I don't mean to sound critical, but changing out numbered parts just ain't good watchmaking. You sound like the type of person who is on their way to becoming hooked on the trade. In no time you will have a lathe and a staking set. The 861 staff is readily available at any material house, and staffing is an easy job. I'd encourage you to wait until you are tooled up. Staffing is a very necessary skill to master, and this is the perfect watch on which to gain experience. BTW, was the hairspring injured in the process? | ||||

|

Mike, Thank you for the information. Where did you get the info about the balances, staffs, and grades? Is this from years of experience, or is there somewhere to look this kind of stuff up?

I saw those scratch marks but I did't realize that they were numbers until you pointed this out. I checked the numbers and guess what? The balance has already been swapped! (The SN of my watch is 21,414,5XX and the SN on the balance is 23,318,4XX). So I guess that there has already been some bad watchmaking going on here.

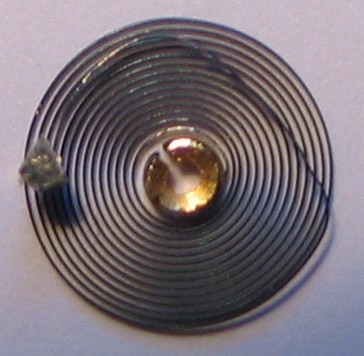

Surprisingly, the hairspring doesn't look too bad. There is a very slight deformation on the inner coil. How does this look to you experts?  | ||||

|

Tony, The elgin information comes from an original 1950 Elgin materials catalogue. I wish my memory was that good The balance that is in your watch came out of a 16S 7J Hunter grade 290. | ||||

|

Wow, not only was the balance swapped, but it was swapped with a balance that never should have been in this watch in the first place! Ebay is a real scary place. The information that you have given me is valuable. Not only do I have a better idea about what kind of parts watch to look for, but now I don't feel as quite as bad about the staff pivot breaking. (I never would have known that it had been swapped with an incorrect balance). I'm still open to any suggestions where to get a replacement. | ||||

|

Tony just my opinion.I would put that one aside for now and get another watch to clean and oil.Also one recommendation.Replace the mainspring when you clean and oil the next watch.It helps to know the spring is new, and if it is weak or sticky, at least you could rule that out because you know you changed the m spring. I have cleaned and oiled watches in the past and the performance of the watch after was poor, because the spring was weak or set. Just my thoughts on this. | ||||

|

Thanks for that suggestion Kevin. This reasoning sounds similar to why you would want to change the water pump when you change the timing belt on a car. You already have the whole thing apart and it doesn't require much extra expense, so you might as well do it. BTW, I already have two other watches to work on. (One is a 6s, so I'm saving that one 'til later on). | ||||

|

Tony This worked for me. The first watch that I serviced was a Hamilton 974 that I bought on ebay. It was absolutely perfect.... dial, case, hands, movement, but it wouldn't run. I bought it in non-running condition and the price was right. I also was reasonably sure that no one had butchered it. After disassembling it and cleaning the parts, I had access to another, totally junk, 974 from the "parts" drawer. At every stage, I performed the necssary procedures on the part's watch until I was 100% confident. Then, I did that procedure on my watch. It was slow going. The job took me two solid days but I didn't break a single part on either watch. I think the fact that I did my initial work on a "parts-watch" took a lot of the tension away. When I worked on "my" watch, I had the confidence of having done each procedure multiple times. That watch runs very well and look like new, except for a slight wave in the case-back that I decided not to "improve" out of fear of making it worse.  | ||||

|

Hi Tony, You might have limited yourself to cleanings & simple tasks only, whereas now you can cease the opportunity to learn and go beyond that. I on the other hand have not had the opportunity to go beyond removing dials, crystals, crowns & stems and letting down mainsprings. I think your mishap was a blessing in disguise. I like your analogy with the water pump. Barbara | ||||

|

A mechanically inclined person, can learn to take a watch apart and clean and oil it.It looks alot harder than it is.It is easy to say that after you have cleaned a 100 or so, but we all start from somewhere.Many people here have the skill, and are honing their skills.Accidents can and will happen to anybody.But if you limit some of risks, you will have more sucess stories.By risks i mean, try to work in a quiet environment, nothing worse than a ringing phone or maybe a family pet being startled, when putting a balance assembly back in. Use good quality tools, and know the procedure, read as much you can find on the subject.Don,t be afraid to ask beginner questions.The greenboard and this board have alot of good information on watch repair. Best of luck to all who go ahead with their learning in this fascinating hobby. | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  1st watch cleaning experience...success...disaster...help

1st watch cleaning experience...success...disaster...help

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  1st watch cleaning experience...success...disaster...help

1st watch cleaning experience...success...disaster...help©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide