| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Elgin Timing Screw Washers

Elgin Timing Screw Washers

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Elgin Timing Screw Washers

Elgin Timing Screw WashersGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hi all. Well I've been playing with my 1924 BWR serial #27999384 for a while and have tried different timing screws on the Invar balance and the time is still out and I just don't have the right sized/weighted screws. So looking for timing washers to add just a bit more weight, as I'm very close, but still more than what the regultor can adjust for. Where or who sells something like this? Thank you, Roland. R. Glenn | |||

|

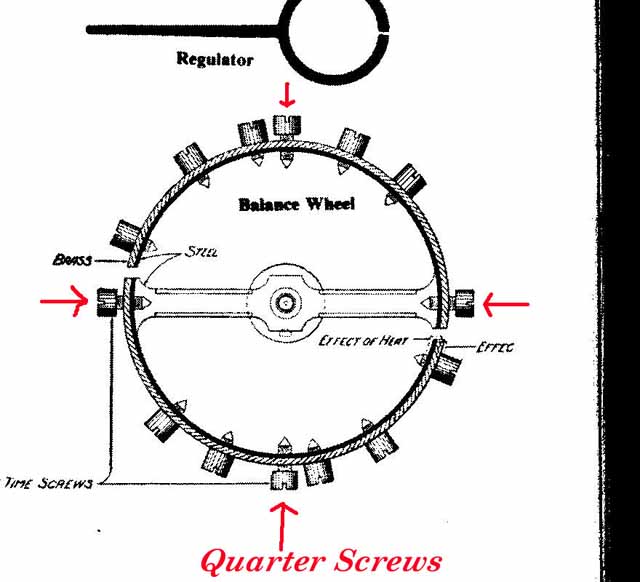

Came across this image from a prior post by David. And this info from another site about adjusting the timing on a balance. "While all compensated balances employ a series of screws for temperature compensation, most are outfitted with four screws at equal distances from each other, with notably longer taps as well. These are the Quarter screws. They are never moved for temperature adjustment, but are for poising the balance or for small timing alterations. Drawing one out a little makes that part of the rim heavier. Drawing out an opposite pair will slow the watch. Turning a pair in will make it go faster. In the best balances Quarter nuts are fitted instead of screws. A Quarter nut is a gold nut, which turns on a fixed steel screw, and is not so liable to work loose the way a plain Quarter screw is liable to with frequent turnings. A Quarter nut is split, and slightly sprung on to its screw to move firmly and not get loose. Timing screws can also be used for poising and timing plain balances as well." So are the quarter screws the only ones you use to adjust the speed? I didn't know that and while working on my balance thought a couple were loose and turned them in. So I've not got to turn them out again. Now the movement was still running fast, so can I just turn out the other 2 timing screws and get it closer? This all comes from a 1924 Elgin BWR that was missing one timing screw, so I replaced it in pairs and the movement then ran too slow. So I replaced those 2 screws with smaller ones and it now runs about 5 min too fast in 24hrs. Originally this movement ran about 15 minutes too fast in 24hrs so I'm getting there, but foolishly turned in the quarter screws. Live and learn and this forum is awesome for the learning part. Just over a year ago I wasn't even playing with watches. Roland. R. Glenn  | ||||

|

Where I'm going in this thread, is that timing washers probably aren't the fix and turning the quarter screw out will do the job. Am I correct on this? Roland. R. Glenn | ||||

|

Ok, so I've turned out all 4 quarter screws The ones at 12 and 6 position by 1 full turn and the ones at the ends of the balance yoke by 1 1/2 turns and we'll see how much that slows the movement down.... Will post tomorrow the results. R. Glenn | ||||

|

And as always after pulling a balance and reinstalling I will demagnetize the movement just incase I've gone and touched a part with a screw driver that needed to feel attached to a screw or too. R. Glenn | ||||

|

Well I think I'm on the right path. After 24hrs I have only gained 1 minute. It used to gain 10. So turning out the quarter screws is the way, or at least I sure hope so. I made sure that after the screws were turned in, that I turned them out exactly the same amount, and that the screws were exactly the same size. So what I've done now is to turn the 2 quarter scews that are on the balance yoke a 1/2 turn more out and that should be it. I'm one of those guys that likes to have the regulator set right in the middle between F and S. So if this next adjstment does it great and if it now is too much I'll dial those 2 screws back in a 1/4 turn. After that it'll be up to the regulator to get it spot on. Will update again on this fun topic Roland R. Glenn | ||||

|

| IHC Life Member |

Please do, it´s very interesting and educating and that´s what we are here for, right. Regards Krister | |||

|

Roland, You'll probably want to poise the balance at some point. I just poised my second balance yesterday and it took a long time but the results are worth it. RR | ||||

|

Well I think that's about it for this movement. It is running right on time now and the regulator is right in the middle at neutral, so if I need to get any very small adjustments to get it within 30 seconds a week I can get it from the regulator now. I spent most of yesterday going through my other pocket watches that were either adjusted by the regulator to max F or S and either turned the quarter screws out to slow, or in the speed the movements out and as of today surprisingly they are all way better and the regulators on those others are turned back to neutral. I found the older 18s movements were very easy to work on compared to the 16's. With the 16s you have to remove the balance to get access to the quarter screws. As for poising the balance, not sure how to do that even after reading about it. All I know is that all the other screws on a balance are for balance, heat and cold etc. but the quater screws are for timing. I made sure the each quater screw was turned either out or in the exact same amount and you do them in pairs (balance yoke ones first) so the poise shouldn't have been effected as the results on this Elgin BWR that was 10 minutes out originally and is now spot on seems to have done the job without getting too technical or complicated as i'm by no means a watch repairman. Roland. R. Glenn | ||||

|

Just to follow up on this. The Elgin is still running absolutely on time, so this one can now take a break from my screw drivers. The other that have been adjusted are also now keeping very good time. Kinda scary actually looking at them all and they read the same time give or take a few seconds. I only came across one movement a key wind Hampden Springfield that actually had timing washers behind the quarter screws. All the rest just had the screws turned out. Roland. R. Glenn | ||||

|

HI,Turn to diff. pos.see how it runs then. Most all watches can be timed in one pos.Try dial up,dial down,stem up,right & left.(5 pos,) All pos.should run same.Dial up & dial down should alway run same.To get vertical pos.to run together takes a little more work.This is where poise(balance)comes in.Good bal. motion is a must. | ||||

|

Came across this bit of info on Poising a balance. I tried the Elgin in other positions and not too bad. Worst was pendent down where I lost a minute. So I turned in the opposite to yoke quarter screws and turned out the yoke screws by the same amount and that got it back into time. Not the best quality of way of doing this but getting there. I'll look into getting a poising tool. Anyways here's the blurb: Poising the balance To check the balance for poise means you check to see if it is heavier on one side than the other. The poise of the balance is very important, you will not be able to time the movement to positions other than dial up or dial down if the balance is out of poise. To poise the balance you must first make sure the balance pivots are straight, polished and clean, Now make sure the poising tool is clean and level then set the balance on the poising tool so that only the pivots are resting in the blades of the tool, next take you hand away and let the balance roll freely, when it stops take note of the place on the balance that is farthest down and rotate the balance so that point is on top, then let go of the balance again and if it stops with the place you noted in the same spot as before the balance is probably heavier at that point and needs to be adjusted however it is always a good idea to check this several times until you are absolutely sure before you proceed. To poise the balance you need to take weight away from the heavy point on the balance, you can do this in several different ways but the method I use and find quite satisfactory is to remove weight from the back of the screw where it can't be seen. I you a screw undercutting tool which only removes material from the inner portion of the back of the screw and leaves the rest of the screw intact, this leaves no marks to be seen from the outside and the balance is left looking untouched. There are other tools that can be used that take material away from the head of the screw, I know of two tools that do this, one of which takes the material away from the outer edge by chamfering it and the other bores a small hole in the center of the head of the screw. One method I do not recommend is filling the heads of the screws down, this method leaves the balance looking hacked and is in my opinion the sign of poor workmanship. Solid balances without screws can be poised by drilling them, usually on the underside of the rim. When poising the balance remove only very small amounts of material at a time or you will be chasing it around the balance for ever. And remember every bit of weight you remove from the balance will directly affect the rate. Before you start removing weight check to see if any of the screws are loose or missing, check the balance arms to be sure they are not bent, make sure the balance is absolutely clean, check the pivots to be sure they are not bent and also check to see if someone has put a timing washer on only one side of the wheel, any of these things are easy to repair by themselves but if you don't see them in the beginning you will just be compounding the problem. You can also add weight by using timing washers but as with taking weight away adding weight also affects the rate. If you suspect that one of the screws is not right for the balance, try finding the proper one, even the lightest timing washer will add a surprising amount of weight. Poising a balance is a fairly simple operation when the proper care is taken. Roland. R. Glenn  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide