| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Watch Case Adventures

Watch Case Adventures

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Watch Case Adventures

Watch Case AdventuresGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

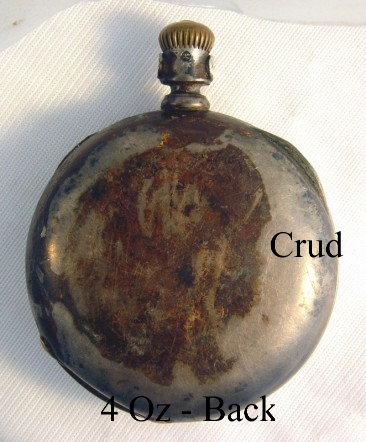

Note: I regret that my photos only show "before and after," not step-by-step stages. I thought I’d share some of the thoughts and procedures that I experienced recently after buying two coin-silver pocket watchcases from Fred Hansen. Some of the decisions and procedures are, frankly, controversial. Therefore, let me be clear that I’m describing what I do and think and not necessarily the opinions of the horological fraternity. First the cases. One is a spectacular massive 5-ounce, triple hinged monster. In my opinion, a 3oz case is “standard,” a 4oz case is “heavy” and a 5 oz case is a seldom seen “brick.” I once paid dearly for a 6-oz case and I’ve heard of really huge cases as well. But I have never seen any of them bigger than the 6 oz that I currently own. I grabbed this case as soon as Fred put it up and worried about what it needed later. The other was a nice “heavy,” 4-oz Dueber, also triple hinged. Both turned out to have the positives and negatives. Both had very good hinges, not surprising when you consider the sheer size and bulk of them. Both had good covers that snapped shut and opened to 90 degrees. Both had some battle-scars but were relatively free of dings with nothing major. They were both still sound, with many years of function still intact.  | |||

|

The negatives were there too. The 5-oz case lacked a crystal and it’s very size pretty much dictated a massive, thick crystal to match. They are getting scarcer but they are around. The 4oz case had an intact crystal but I couldn’t tell whether it was badly scratched or just covered with stubborn filth. Both cases were nearly black. The 5oz had an even coat of dark tarnish. The 4oz was covered with “something’ that was well raised from the surface and came-away (some) when rubbed with a fingernail. More about tarnish later. The 4oz Dueber was missing a bow and had a very badly worn brass crown, with a good, intact, stem. The first order of business was to procure the necessary parts for restoration. A 185 member advertises these old crystals for very reasonable prices. But he prefers measurements rather than undertaking to fit them (which he also will do). I decide to check our shop. We do have some crystals but they are getting scarce and are reserved for worthwhile cases; the 5oz qualifies. I’m in luck; the sheer size of that case saves me. It takes one of the #20 size crystals. The #19’s are the tough ones because so many cases used them. I find a crystal that is a tad too small. It can be glued in but I won’t get a “glue-less fit. Since the watch won’t be carried, I’ll settle for it. It is a NOS, thick, beveled crystal with the label still on. I soak the label off and I’m relieved that the label-glue has not etched the glass. I’m also having a lucky day with the 4oz case. Since it’s a Dueber, our junk drawer yields lots of old cases and parts that look similar. With very little searching I find a nearly new brass crown. Other times, I’ve searched through hundreds of crowns with no luck. The bow is even easier but I’m apprehensive that it might be plated. If so, the plate will not survive buffing. I take a chance and install it with the use of a ‘reverse” long-nose pliers and tighten it with a bow-pliers.  | ||||

|

Now, I have to decide on cleaning the cases. There’s a split amongst collectors on cleaning. Some regard the tarnish as part of the watchcase’s history and refer to it as “patina.” I don’t. I regard it as “dirt” and can’t see the historical value of silver-oxide. I’ll let the proponents of “patina” speak for themselves. I do respect their opinion. And I agree… if we’re looking at George Washington’s watch… his “dirt” is historical. Otherwise…. I also believe that our watch’s former owners probably polished, buffed or otherwise cleaned their silver watches, when they were in use. I know very few people who wear badly tarnished silver jewelry, so it is logical that men felt the same way about their watches. To my mind, the tarnish represents the history of the watch as a discarded item, spending years in a dresser drawer. The decision is easy for these two cases. The 4oz has a hardened foreign substance, probably dried grease, that MUST come off. The 5oz. is a closer issue. The tarnish here is dark and even; the kind that “patina” proponents love. I consider that but I also consider that this is an empty case; there is no movement associated with it. Also, there are some awful case-screw gouges, probably caused by sharp half-screws. They are so bad that the case might not hold a movement. I will be faced with either having a solder-repair made, using unsightly washers or selecting a movement with a different case-screw position. In any event, I will not have a watch that will appear original. With these factors in mind, I opt to polish both cases. Before polishing, I decide to prep both cases. I want to get as much “crud” off the 4oz Dueber as I can. I also dread the idea of removing that much tarnish with the soft red-rouge that I use. Disclaimer: The procedures that I will discuss below are definitely in the category of ‘don’t attempt this at home.” Although I have used some of them for many cases, I have no doubt that they can be dangerous if not done with proper equipment, training and experience. More about that later. I decide to give the 4oz Dueber a bath in sudsy-ammonia to see if some or all of the dried “crud” will break off. Sudsy-ammonia is a weakened solution with detergent added for dual cleaning power. I use a rather large ultra-sound tank with it. I am pleased that most of the “crud” comes right off. As a bonus, the crystal comes very clean as well and shows itself to be in very good condition. After removing the grime, the case shows only light tarnish.  | ||||

|

The 5oz. however is dark. I decide to take a chance and do something that I’ve never done. I decide to use Tarn-ex, a popular silver cleaner. I’m afraid that too much buffing will be necessary to remove that coating. A very quick bath in Tarn-ex removes almost all of the tarnish, nearly immediately. But, I can smell sulfur and theorize that it is pretty acidic. Of course, the bottle says it’s “safe” for silver but I have my doubts. So….it comes out of that solution quickly and goes into the ammonia, which is a base and should neutralize any acid. After that both cases are thoroughly rinsed in clear water. After polishing, they will go through a similar process and be thoroughly dried. The 5oz case comes out clean of tarnish but with a milky, even coating that I theorize might be very slight etching caused by the silver-oxide. I think it will buff out very easily. Another disclaimer. I buff my cases. Many people are vehemently opposed to this practice. Honestly, I can see their point. Can a case be ruined by buffing? Yes. Can someone be injured? Yes. I need to reveal that I buff cases on a Vigor jewelry buffer that is specifically made to buff precious metals and jewelry. The buffing wheel is encased in a metal box that will catch a case that is thrown and also draws and filters the very fine red-rouge. The buffer motor has two speeds, low and high; and I have no idea how these speeds correspond (if at all) with the bench grinders that it resembles. I have been thoroughly trained in buffing and have done hundreds of cases. I only use red-rouge, probably the mildest and softest of abrasives that lubricates the cloth buffing wheel, which would otherwise ruin a case. My personal thinking is thus: If someone is foolish enough to use a bench grinder, Dremel tool or harsh abrasives, he does so without my blessing. I also have an Instrument Pilot’s license and routinely flew airplanes in zero-visibility. As with case-buffing, I would not recommend either practice to anyone who does not have the proper equipment and training. But, I also don’t think it necessary to save foolish folks from themselves.  | ||||

|

Both cases buff very easily to a high sheen with a minimum of pressure. This is unusual because, as I noted, silver-oxide is tough and buffing silver cases usually calls for some rather aggressive pressure. I’m glad that I did the “pre-treatment.” Silver cases get very hot when buffed and I feel the heat through the leather gloves that I wear. I’m buffing the 4oz. Dueber WITH the glass crystal still installed. Red rouge is too soft to cut glass. I’ll omit some of the details of buffing since I sincerely hope that most of you won’t try it. Suffice to say, that both cases emerge, intact and showing a brilliant, like new shine. However, as expected, they still carry the now-black residue of the red-rouge polishing agent. Red-rouge is insidious and can be nasty to watches. It comes in hard sticks or bricks but once it hits the polishing wheel it becomes the very finest of powders. It can and will seep into watch movements and quickly stop even the cleanest. Cases are buffed in a garage, well away from our work-benches. So, it is absolutely essential that every bit of residue is removed. The cases go back to the ultra-sound and sudsy ammonia for that. I like to give them two full baths. In the first, they are thoroughly soaked and rinsed in clean water. Then, I visually inspect them and use a fine toothbrush, and clear water, to remove or loosen stubborn residue. Then, they go into another utra-sonic tub of much cleaner solution for a 2nd bath. After that, they are again rinsed in clear water and the visible water is completely removed. I use a cotton cloth and then the lintless Kwik-wipes to manually dry the cases. Any visible water will spot and bake-in during drying. Even thought the cases look dry, they are not. Moisture still exists in hinges and especially inside the stem where it might rust or even work into the movement. The cases are, therefore, dried in fairly high heat (not touchable) for a full 20 minutes. We’ve found that this time will remove all traces of moisture.  | ||||

|

Both cases look wonderful. The Dueber’s crystal has survived all this; especially the high heat of polish and drying. That tells me that the crystal is friction-fit. A crystal, held by glue alone, will fall out in this process. What remains is to install the NOS, thick crystal in the 5oz case. I use a two part crystal glue made by Seiko. It must be mixed before using. It is quite expensive, so care must be taken to mix no more than the job requires. Once mixed, it must be used within minutes. I’ve used other glues but they tend to be sloppy and cause “strings” when I apply them. Some are quite cleanable but the mess is disconcerting when I’m working. The Seiko glue does not form “strings” and even small amounts “flow” into the crystal groove. The special tool I use to apply the glue is proprietary, so I won’t describe it. The bezel will be left to dry overnight. It won’t take that long to dry, although different glues need different drying times. I’ve handled bezels too soon and had crystals fall out. Anyone who has done this knows what kind of mess he faces in removing old glue, in order to reapply it. Better safe than sorry. The cases are now both finished and will now be placed, without glory, in my inventory of available watchcases. Surprised? It’s true, I had no movements in mind when I bought these cases. But, great cases are getting rarer and rarer. Like dials, I will buy virtually ANY case that I think is unusual or that will make-up into a nice watch. It’s no gamble. Either I’ll end up with a stunning pocket watch or…. in the worst case, a very saleable commodity in our hobby.  | ||||

|

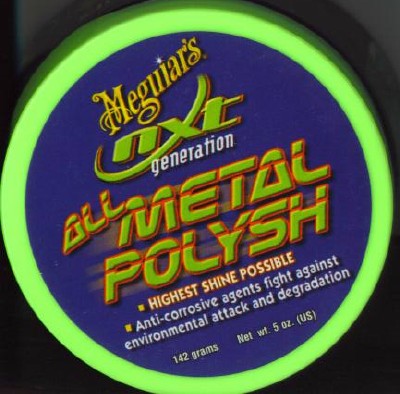

Peter, You did a really nice job on the cases. But may I suggest a safer a easier way of doing the same job. I use a product called "Metal Polysh" that I bought at Farm & Fleet. Really bad cases like you did does take a little extra elbow grease,but you won't have to make a mess with a power buffer. I added a scan of the lid of the product I use in case you want to try it some time. Larry  | ||||

|

I'll try it. McGuires products get high marks in my book. I use it on my cars and their plexiglass products are the only ones that I'll trust on my motorcycle windshields. That said... I realize that power buffing is controversial and I readily admitted that it CAN be dangerous without proper equipment or training. However, I believe that I've satisfied those requirements and I do hundreds of cases without incident. One of the points that folks find hard to believe is the fact that red-rouge buffing causes LESS wear than most non-power buffing with harsher chemicals or abrasives. I know of no abrasive that is softer or milder than red-rouge. That's why it ONLY works on a power buffer. Try it by hand and nothing will happen. By definition, every polishing technique is going to remove metal to some degree. Red-rouge buffing, in my opinion, is the least destructive of all the polishing processes that I know. I realize that some folks will not agree or find it illogical. Everyone is entitled to their opinion. I don't pretend to know everything. Red-rouge polishing is an old technique that goes way back. I'm glad to be able to discuss it openly and to hear other views. IF I were to use a chemical or hand-abrasive, I would still insist upon a thorough cleaning and drying. A serviced watch-movement MUST be protected from any kind of contamination. Thanks again for your input. | ||||

|

| IHC Member 163 |

Absolutely beautiful jobs, Peter!! I love silver cases, especially BIG cases, so needless to say, you held my attention!! Wish I could have caught up with you when we were out in Phoenix a couple weeks ago visiting our eldest daughter....but we hardly had time to do what SHE had laid out as our agenda...and as far as WE were concerned, it was her show! Maybe next time... HIGH regards, my friend. I love those cases! Mark | |||

|

Peter, I do agree that red-rouge buffing is very effective. It can be used for a lot of things,cases included. I just mentioned the "metal polysh" as an alternitive to red-rouge buffing for people who may not have a buffer or a place to use one. Like myself for example. I have my work shop set up in a spare bedroom and hand polishing cases works best for me. Less mess. BTW,my heart always skips a beat when I see a big silver case all polished up. Yours are a good example. Larry | ||||

|

I agree 100%. And, if I didn't have proper equipment, I would do the same. Even now, every so often, a case will "get away." With my set-up there is no personal danger, although it's not the best thing for the case! Perhaps you can tell us if you take any precautions after cleaning a case with that McGuires polish. It advertises "protection" against tarnish, which tells me that it may be leaving a residue or film. Have you found that to be a problem? | ||||

|

Meguiare's is a green colored paste that does get into small cracks and crevices when you polish a case. I usually take the case apart when I'm done polishing and run it through a cycle with the ultasonic cleaner using a water based jewery cleaner. Then I rinse with tap water and dip in denatured alcohol. Larry | ||||

|

That sounds like you have the cleaning covered. I would do something similar with the pink chrome pastes as well. They advertise that they do leave a protective film and I'd be wary of that anywhere near a movement. A cheap dryer can be made by punching a large hole into a shoe box and using a hair dryer. Be sure to vent the heat or it will get too hot and trigger the safety cut-off. | ||||

|

| IHC Life Member |

"--- a two part crystal glue made by Seiko" Ah - you must be using Seiko S-310 ? Great stuff, I use it for all non-round wristwatch crystals. DM | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide