| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Most prevelant reason for a pocket watch not running

Most prevelant reason for a pocket watch not running

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Most prevelant reason for a pocket watch not running

Most prevelant reason for a pocket watch not runningGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

From what I have seen of this forum there are probably thousands of years of experience in watch making and repair among members. I was interested in a sort of a poll of experienced repair people as to the most common reasons that old pocket watches stop running. I don't know enough to know all the possible reasons ( I am sure there are hundreds). I was interested in a consensus from a broad base of experienced people of their opinions. Examples of reasons and % of watches effected: 1. Cleaning - gum in jewels, dust, dirt grime 50% 2. Damage to balance staff 10% 3. Damage to balance wheel 5 % 4. damage to hair spring 3% 5. damage to main spring - broken 20% 6. damage to main spring - connection to barrel etc 7. damage to staff - winding , setting ? etc Again these are just a limited number of reasons that my inexperienced mind came up with. Someone with more experience could come up with a more comprehensive and reasonable list to start with. Then we could get opinions on which are the most likely reasons for a watch to stop. Again I understand that there are hundreds of reasons for a watch to stop, but if there was information like this available it would be interesting in developing a road map of things to check for when analyzing and evaluating a non working pocket watch. Hope this not to presumptuous for a new member. Hope you are all having a great day !! Bob Williams | |||

|

| IHC Life Member South-Bend |

The majority (over 50%) would have to be broken staff. Other things to add to your list are missing/broken roller jewel, missing/mis-aligned pallet jewels and broken train jewels. Also, while there are many reasons for a pocket watch to not run at all there are even more reasons for a pocket watch to run poorly. | |||

|

Thank you for your insight , any other opinions ? Bob Williams | ||||

|

| IHC Member |

Hey Bob-Have you seen this small book-"Watch Repairing-as a hobby"-by D.W.Fletcher? You can get it used cheap and it will help answer lots of initial questions;it's only about 60 pages but packed with info and illustrations. Marty | |||

|

| IHC Life Member |

My list would go; Dirty Dirty and Broken Staff Dirty and Broken Main Spring Dirty and Missing Roller Pin Dirty and Bent, Broken Train staffs Dirty and missing wheel pivots (one of my favorites) Dirty and Grenaded Pivot Jewels Dirty and damaged or rubbing balance (hair) spring Any of the 625 combinations that are possible from the above list. | |||

|

| IHC Life Member South-Bend |

David - Does "Grenaded" mean something like "pitted". I've never heard that term. From the original poster (Bob) you said: "Again I understand that there are hundreds of reasons for a watch to stop, but if there was information like this available it would be interesting in developing a road map of things to check for when analyzing and evaluating a non working pocket watch." In many cases it depends on why you're evaluating the watch. If I'm fixing the watch for someone else I'm basically looking for anything that can stop the train or interfere with the escapement. The road map for me is not the same depending on what the reason for fixing it is. If it's part of my private collection I will look over a watch and depending on how valuable the watch is will be looking for the watches that are the easiest to repair. If the watch has too many problems and is a lower grade then it's very likely to end up a parts watch. And then there's always evaluating a watch that you're looking to purchase... then it's a very different deal. There I'm always looking especially hard at the things that are the hardest to fix or replace. | |||

|

| IHC Life Member Certified Watchmaker |

A interesting point to make is the more complex and higher value (not value created by some recently identifed rarity) the more I enjoy working on them as they suffer far less from the list fo problem above, normally just dirt/oil migration or genuine wear. | |||

|

Great responses as always , now a follow up question . Other than cleaning the rest sound like pretty intricate and sensitive repairs. How would you rate the difficulty of repairs as listed. Given the amount of work , specialty tools, availability of parts and the level of expertise necessary to complete the repair ? No hidden agenda just a curious interest in the opinion of experienced repair people. Bob Williams | ||||

|

| IHC Life Member South-Bend |

How would you rate the difficulty of repairs as listed. Given the amount of work , specialty tools, availability of parts and the level of expertise necessary to complete the repair ? Availability of parts is moot if the watchmaker is good enough. Making a new staff, pinion or other part from scratch takes varying degrees of skill. Straightening out badly mangled hairsprings, pinning and studding, vibrating a new hairspring; those are all things that require a lot of practice. Really good lathe work and hairspring work probably require the most expertise. Also, the answer to your question is largely determined by the skill of the watchmaker, i.e., "How would you rate the difficulty...?" I see quite a few "repairs" that are just wrong, e.g., a collet that has been glued to the staff because it was loose. Horrible mutilation of the mainplate under the bridge. Sanded down pallet bridges. Mutilated timing screws. Very badly formed hairsprings that put the positional timing completely out of whack. Sometimes it's not a matter of having a specialty tool, depending on what you mean by "specialty". I remember getting this tool in a grab-bag at a show and I had no idea what it did. Every time I worked on a watch I would pull out this tool for a second and try to figure out what it was for. When I figure it out it become one my regular tools and I threw away the one I had been using for the same purpose.  | |||

|

| IHC Member |

Don't leave me hanging,Frank! Tell me what this is and how it's used- Please! ...Is it spring loaded? Marty | |||

|

| IHC Life Member Certified Watchmaker |

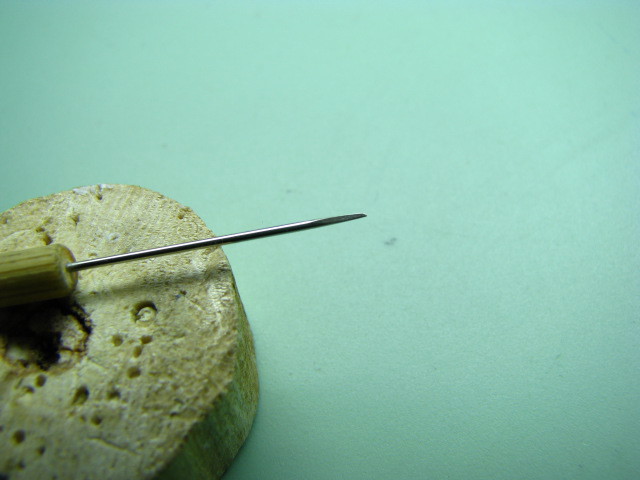

Hey Marty, I have a set of thsoe but still prefer this one still hanging  | |||

|

| IHC Member |

OK, Chris-that looks like an extra fine oiler; but it could be a poker for assembly.I'm guessing oiler,it looks like it has a slight hollow at the tip to hold a little drop...But I can't see that in Frank's tool-what am I missing? Bob! Where are you? These guys are gangin'up on me! Marty | |||

|

| IHC Life Member South-Bend |

It's a tool to rotate the collet while it's on the staff. | |||

|

Sorry Marty , but this discussion string has gotten over my head. It started as a discussion on general diagnosis as to why pocket watches don't run and ended up with discussion on a tool that I don't even understand the explanation for. I guess a discussion string is like a box of chocolates , you don't know what kind of discussion it will be until you bite into it. Thanks to all for information. If there are any others who would like to comment on " diagnosis" I'd be happy to hear your opinions. Bob Williams | ||||

|

| IHC Life Member |

Bob what you have seen unfold here is all our opinions of what it takes and what we feel comfortable to do to repair a watch, and even why we (bother to) do it. | |||

|

Dave , thank you for your continued willingness to share your knowledge and experience with us. Bob Williams | ||||

|

| IHC Member |

Bob-Don't get discouraged,I'm only a few guys ahead of you in #185-I had to search for the same answers you need now. Half the time it's only a matter of learning the lingo-once your vocabulary grows you won't feel so lost. I keep a list of any word that's new to me and look it up later; everything is connected and that helps...You know,like the toe bone connected to the ankle bone analogy. And lots of old tools are a mystery to all but a few experts. There might be more tools than pocket watches... If it wasn't like this, and I didn't have one question and challenge after another,I would be bored silly. I look forward to your questions-keep 'em coming! (See how far off I was guessing the above?) Marty | |||

|

Thanks for the encouragement Marty ,you are right, the complexity of the topics does make them interesting. Bob Williams | ||||

|

| IHC Life Member South-Bend |

I think if you just read down Chris Abell's watch service checklist checklist you'll find that most of the items deal with some issue that is going to affect the power train. That's the long and short of it, the power train and the ability to make it run as smoothly as possible by removing as much impediment (usually friction) as possible. Except for a few oddball cases all of my watchmaking has involved finding problem areas due to wear and friction and taking appropriate action. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Most prevelant reason for a pocket watch not running

Most prevelant reason for a pocket watch not running

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Most prevelant reason for a pocket watch not running

Most prevelant reason for a pocket watch not running©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide