| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  screwded down jewel settings

screwded down jewel settings

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  screwded down jewel settings

screwded down jewel settingsGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

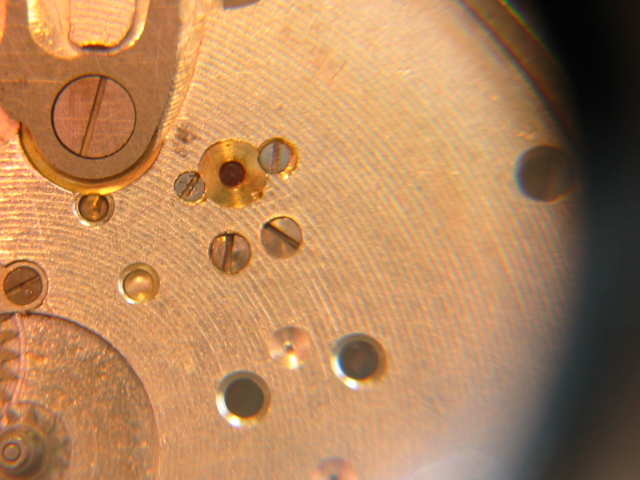

I want to remove this jewel from one movement and put it in another.Is there anything special i should take precautions or be aware of.I have alreaady checked ser numbers and both are same size name and grade. IHC Member 261 Chapter 111,Ottawa NAWCC Member 158976, Nepean, Canada  | |||

|

| IHC Life Member |

Kevin, First, you need to condsider if the hole jewel is the correct pivot size. Although both watches may appear identical in all respects, their balance pivot sizes could be different. After removal and cleaning, check the donar hole jewel on the lower balance pivot of the receiving balance. If you haven't removed lower balance jewels before, you will need to: 1. Remove the screws securing the cap jewel. 2. From the opposite side of the plate, push the hole and cap jewels out with a jewel pusher. You will use the same pusher to reinstall the jewels into the receiving watch. Note the machined lip on one side of the hole jewel bezel. Be sure to install the jewel with that side down (facing the balance pivot). 3. Set the donar hole jewel into the other watch plate making sure the lip (oil cup side) side is down. Push the jewel in until it is seated in the hole. If the jewel gets cocked in the hole, remove it and start over. DO NOT FORCE IT IN or you will crack the jewel. 4. If possible, use the existing cap jewel of the receiving watch. Drop a small amount of oil on top of the hole jewel. Align the screw cut-outs and push the cap jewel into place. Install the screws. NOTE: Since you're probably cleaning and oiling the movement, you should clean the jewels before installation. You need to clean the upper balance jewels too. John D. Duvall Vice President, Education  | |||

|

I have done what you said and it went reasonably well.The only problem i found after was the threads on the movement plate it was going into was stripped, after i put the screw back in i used locktite.Then i thought to my self that the balance was from one of my parts movements and the lower jewel was not from the same movement so pivot sizes on each end are not necesarily the same sizeAlso another problem i dont think the balance i put in was compatible with that grade i will check it over.It came from a waltham travelller model and was goinh into a 16 sz waltham? Will get back to that one later. IHC Member 261 Chapter 111,Ottawa NAWCC Member 158976, Nepean, Canada | ||||

|

| Watch Repair Expert |

Perhaps it's only used as an illustration, but the watch in image above is an Elgin. If you're trying to install a Waltham balance into it, you can be assured that it won't work. As for oiling jewels, a small dab of oil should be applied to the CAP jewel, not the hole jewel, prior to uniting the two. If you oil the hole jewel, the oil will be drawn through the hole and into the cupped side of the jewel, which is NOT where you want it. By oiling the CAP jewel instead, you can see exactly how much oil you've applied, and there isn't any place for it to go until you unite it with the hole jewel. Even then, the capillary attraction is strong enough to hold the oil between the two jewels, rather than allowing it to go through the hole jewel and into the cup inside. The "cupped" side of the hole jewel isn't intended as an oil reservoir, it's simply to allow room for the conical portion of the balance pivot. No oil should ever be in that part of the jewel. ================================ Steve Maddox President, Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

| Watch Repair Expert |

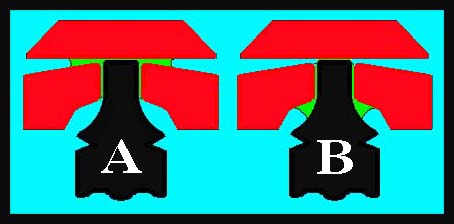

The following sketch shows a cross-sectional view of a conical pivot, passing through a hole jewel and resting against a cap jewel. In the sketch, the jewels are red, the pivot is black, and the oil is green. "A" shows oil where it's supposed to be. "B" shows oil where it's NOT supposed to be. ======================= SM  | |||

|

Thanks as always for your help Steve, i have been working on two watches, one is a Elgin and the other a Waltham i mixed myself up in what i had said eaelier, two different watches and 2 different problems. I always thought it was good to oil the lower jewel. If the oil was where you show in B, would this slow down the watch? IHC Member 261 Chapter 111,Ottawa NAWCC Member 158976, Nepean, Canada | ||||

|

| Watch Repair Expert |

It wouldn't slow the rate, at least not at first, but it would knock a few degrees off the balance amplitude, and that would worsen as time passed and the oil began to thicken. Also, the oil as situated in "B" is more exposed to evaporation and particulate contamination, and is more inclined to "creep" up the balance staff. It just isn't good watchmaking practice..... ====================== SM | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide