| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Hamilton Elinvar

Hamilton Elinvar

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Hamilton Elinvar

Hamilton ElinvarGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

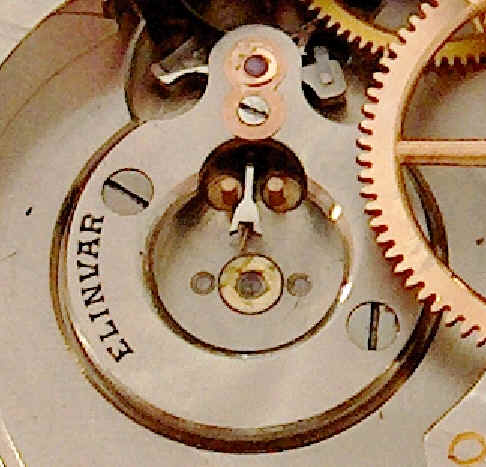

I friend of mine asked me to take a look at his Grandfather's watch - a Hamilton Elinvar 21J. He told me that it was dropped X many years ago, repaired (not by me), and it never ran good ever since. I took it apart and noticed two things - the safety roller was not completele seated on its shoulder and the pallet fork pin was bent. I finished seating the safety roller but have no idea what to do about the bent pallet fork pin. Is this something that can be straigntened or is it best to install a new pallet fork? Thanks  | |||

|

Yes these can be straightened.I use a heavy tweezer. Slowly move the pin to the center of the fork.Sight down the bottom of the fork over the pallet arbor,the center of the pallet arm(?)and over the pin.Get them all in one line. also check the pin from the side to keep the end of the pin in the safety roller cutout. Hope this helps. J Smith | ||||

|

Thank you very much. I have never straigntened a pallet fork pin before. Is it very brittle? I take it the keys are slow and slight. | ||||

|

| IHC Life Member |

Hi Mark, You should remove the pallet fork from the movement before attempting any manipulations on the guard pin (finger). The pin is not brittle but "slow" and "slight" are good words to consider when working around watches! Also, if you don't have heavy tweezers, you can use a flat or round nosed staking punch of the appropriate size as a lever. Small needle nose pliers should also do the trick. Since the roller table was loose and could have turned slightly on the staff, you should also check the "beat" of the watch. Good luck!! | |||

|

Using a punch is a great idea. Thanks | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide