| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Too much fun with a model 1857?

Too much fun with a model 1857?

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Too much fun with a model 1857?

Too much fun with a model 1857?Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

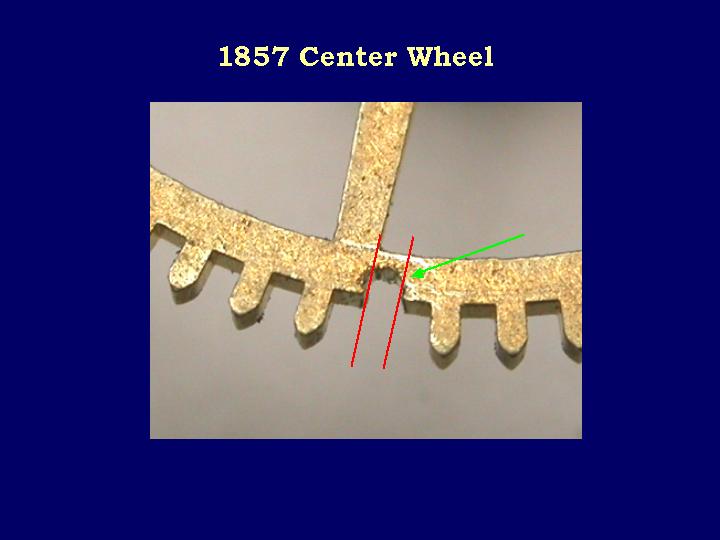

I've been spending a lot of overtime on this old model 1857 movement. I got the new #279 staff pivots reduced and it's now riveted to the balance. The tip of the balance cock had been tweaked up during the last repivoting (according to a steel straight edge) which now causes the wheel to drag on the balance cock in the dial up position. Tweaking it down about .02mm provides wheel clearance but I lost the end shake. I still may be able to take about .01mm to .02mm off the bottom pivot but that will be my last resort. Although currently not dragging, it stills leaves the wheel running quite close to the balance cock. I was wondering if the staff balance seat should have been cut a little further down into the hub but would that create clearance problems between the hairspring and the regulator arm? Meanwhile, I cleaned all of the parts and noticed a tooth bent on the center wheel. I assembled the center wheel and 3rd wheel just to see if the tooth would pass through the 3rd wheel pinion leaves and it did. I now assume this watch had been running with a bent tooth but may have not achieved a full run down. Further examination revealed a previous tooth repair. I then concluded that this watch had probably suffered through at least two mainspring breakages. Not having a safety pinion, the center wheel teeth were damaged. I'm attempting a repair on the center wheel but it's kind of hard to cut a regular dovetail groove in something this small. The older repair was just a straight cut and is already showing signs of some bending. Also, another tooth or two is slightly bent which is cause enough to look for another center wheel. Does anyone know if any other 1857 models had a center wheel with safety pinion and if so, would it fit this movement? The first slide shows the bent tooth and the old repair. The second slide is my poor attempt at creating a partial dovetailed groove for a single tooth repair. The green arrow is pointing to an area where I need to remove a little more material. I'm afraid the cut may be already a little too deep. The repair plug will be a slightly thicker piece of brass than the wheel so I can spread it before soldering. Can anyone suggest the best solder to use? This is my first and probably last 1857 that I will want to work on. They're just too much fun! John D. Duvall Vice President, Education  | ||

|

| IHC Life Member |

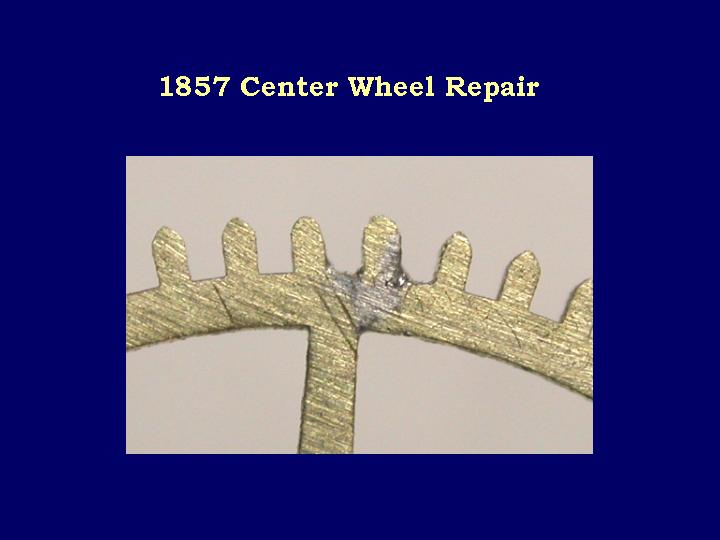

Cut made in center wheel for repair plug. John D. Duvall Vice President, Education  | |||

|

| Watch Repair Expert |

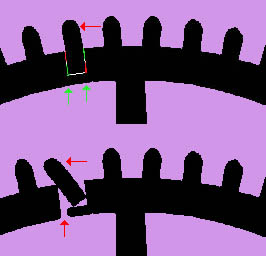

This is not meant as an "I told you so," and I hope it's not taken that way, but I had a good idea this is how things would go with that watch. The "Home Watch Co." models were Waltham's lowest grade product, and they're even more "crude" than the "average" 1857 models. Although the parts in the 1857 models were mostly "machine made," they also had a LOT of hand finishing, which can cause huge problems with parts replacement. The issues with the balance staffs are why I initially said there are a number of different variations. Although two 1857 staffs may look exactly alike, they may have important differences that are not readily apparent, nor easily discernible. I hope people will better understand now why I declined to tackle that job, and why I predicted the cost of repairs would be relatively significant. My estimate here actually prompted some ridicule on the "green board," obviously from someone with a very limited knowledge of watch repairs (even though he claims to have the "world's greatest collection" of early American watches). Now, as to the particular issues at hand...... The "cure" for the balance problems will probably involve bending the rim slightly downward (in umbrella fashion), in order to keep it away from the balance cock without diminishing the space beneath for the hairspring. Obviously, one doesn't need to get carried away, but a little bit won't be noticeable, and it won't hurt anything. Of course, as those watches are nearing 150 years old, I can't comfortably say that I've ever worked on one that was "factory original," but I have seen a number with somewhat "creative modifications" that I believe would have always been necessary. As for the center wheel issues, I'm not sure that any 1857 models ever had safety pinions, but the better grades did have stopworks, which greatly reduced mainspring failure. In this case, the best solution would be to install a new white alloy mainspring, and not modify anything else in the movement. Be sure to wind the spring tight by hand before installing the barrel in the movement, just to make sure nothing slips. If a "disaster" happens, it's better for it to happen with the barrel in the fingers, rather than in the watch. The old tooth repair doesn't look very "professional," but I've seen countless examples just like it. For replacing teeth in watch wheels, it isn't as important to "dovetail" the fit as it is in clock wheels, but it IS important to be sure the new tooth fits perfectly into its slot. It's also best not to cut more than 2/3 through the rim of the wheel, for reasons I'll attempt to illustrate below. Any "slop" in the fit of the new tooth will allow it to gain increasing amounts of "leverage" in the slot, and if the rim is weakened sufficiently, the leverage can allow the new tooth to pry the rim of the wheel in two. The solder I'd recommend is "Harris Stay-Brite," which is a relatively hard "soft solder" that's easy to use, and contains no lead. It melts at less than 500 degrees, which will not anneal the brass. If gold or silver solder is used, the bond to the tooth will be much stronger, but the wheel itself will be annealed, and there's no way to harden it again afterwards. Unlike steel and other ferrous metals, brass cannot be hardened and tempered by heating and quenching, it must instead be "work hardened" by rolling or pounding with mechanical pressure. Needless to say, there's no way to do that to a finished part without distorting it, so once a brass wheel has been annealed, there's no way to ever harden it again successfully. While solder adheres fairly well to metal, it doesn't have much tensile strength, and it will readily compress. Again, that's the reason a tight fit in the slot is important. When one replaces a tooth in the fashion shown below, mechanical forces are introduced that aren't present in the original wheel. Correctly done, the repair can be successful, but if done badly, the wheel can actually break, thereby causing even greater problems than existed before. One last thing... Be sure to check the third wheel pivots to see if they're bent; it's obviously the interaction between the center wheel and the third wheel pinion that bends the teeth on the center wheel, and the same interaction can also bend the third wheel pivots. Also, check the teeth on the mainspring barrel, as those typically bend as well when enough force is transmitted to bend center wheel teeth. =================== Steve Maddox Past President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49  | |||

|

Steve and John, that was an extremely interesting and educational post. Steve, that was perfectly articulated,and i understood everything you wrote and illustrated perfectly,how rare and how nice for me. Thanks for the insites to your world! | ||||

|

| IHC Life Member |

Stephen, This was my first experience with an 1857 and I now understand fully what Steve was warning everyone about. I like to share my repair experiences with everyone. Especially those that we don't encounter on a day-to-day basis. Kudo's to Steve for always being there with expert advice. This forum is all about education and sharing with fellow members. John D. Duvall Vice President, Education | |||

|

John, I would "go for it" too ,with a smile on my face,worst case is not that bad in my mind...off it goes to an expert,or replace whatever i damaged...and you are one of our pro's,this tells me this repair may be a bit sticky for anyone..exspecialy me.. even with my unrelated (overlapping) skills and shame full self confidence The Idea of attempting a repair as you have tried is pretty exciting,fun, and tempting to me. I really enjoy reading opinions and experiences from two of our very talented members,as i do from our beginners,I have never failed to learn something from listening to a second opinion.So please keep posting them!!! One time I learned...ignore a second opinion...but that was a exception to the rule! | ||||

|

| IHC Life Member |

Steve, Thanks for all the advice. Do most large hardware stores or hobby shops carry Stay-Brite? I know S.L. LaRose carries it but I would rather buy it locally. I too had thought about an alloy mainspring after discovering the lack of a safety pinion on this movement. The safety pinion had to be one of the all time great improvements for watches. My biggest mistake was assuming that the dimensions of the old staff were correct. The new staff was selected because it was identical except for the hub thickness. The new staff hub was about .02mm thicker. I could have temporarily glued the balance wheel to the staff and checked for clearance dial up but I'm not sure that would have helped either. When I fit checked the staff before staking, it had good end and side shake so I thought I was home free. After staking the wheel on, I was really disappointed to find that the balance wheel now rubbed when it was dial up. When I did a check of the 3rd and center wheel meshing after discovering the bent tooth, the 3rd wheel appeared to run true. I always load the train wheels (without the pallet) and check that all are running true before final assembly. The spring barrel teeth are okay. Even the barrel had a tooth that was repaired. All in all, I look at it as a positive learning experience. The kind that pushes one's patience to the limit. John D. Duvall Vice President, Education | |||

|

| Watch Repair Expert |

There's no doubt that it will be good experience; not a good experience, but good experience. Needless to say, when working on watches, it's usually a bad idea to assume that the previous repairmen of the past all knew what they were doing. That's particularly true of pocket watches, and especially the older ones. Whenever working on older watches, particularly those with "creative" repairs, I often wonder about the conditions under which those repairs were performed. I can just imagine a watchmaker in a little shack, miles from the nearest town, doing the best he can with screwdrivers fashioned from nails, etc., while poking wood into a potbelly stove, or wiping sweat out of his eyes with a dirty handkerchief. I'd hate to have to work on watches that way, and it's entirely possible that those of us who now look upon the work of our predecessors with some derision, simply fail to consider the primitive conditions under which many made their living. I'll bet we'd be shocked, and all things considered, it's probably a wonder many of those guys did as well as they did! In any event, I doubt that most plumbing or hardware stores would carry Harris "Stay-Brite," but I might be wrong (it might be available at a specialty plumbing shop). I bought my first roll from S. LaRose about 10 years ago, and I think I've now used about half of it. I did buy a new roll last summer at the National Convention, but that was mostly just to keep on hand in case it ever got hard to find. Be sure to use the flux that comes with it, and be sure to rinse all the flux thoroughly when you're finished, or the result will be the worst corrosion you've ever seen. If I recall correctly, the flux contains zinc chloride, and it will menace any common metallic objects it remains in contact with for very long. For what it's worth, a moderately bent train wheel pivot won't necessarily make a wheel wobble, but it will make it bind in its hole, thereby producing weird fluctuations of balance amplitude. Also, if the pivot hole isn't jeweled, the wobble of the pivot will rapidly wear the hole, thereby causing premature failure of the watch. As a bent pivot rotates in a relatively deep hole, it essentially has the effect of being oblong or elliptical in shape. That's a little different than what happens with bent balance pivots, because only the tips of those run in holes. A balance wheel (or a cap jeweled escape wheel) with a bent pivot will wobble significantly, but that isn't typically true of ordinary train wheels. ==================== SM | |||

|

Not to break the thread,but speaking of teeth;I read the thread,and found a problem with one of my movements that I hadn't pickup-on,an Elgin 18s. After it ran for a while ,it would stop.I checked the gear train, and everything seemed okay.I never checked the teeth on the barrel,assuming they were good.Big mistake. after readind John's thread, I checked all the way back to the mainspring;a bent tooth was stopping the movement when it reached that tooth.The watch had problems when I aquired it. Problem solved,straightened the tooth; watch running fine.I don't know if the barrel is original to the movement,but the center wheel teeth are not bent,best I could make out. Moral of the story,never assume anything. p.s. Did I ever tell you the story about the time I went to the Dentist....... Frank Frank Juchniewicz [This message was edited by Frank Juchniewicz on March 26, 2004 at 23:55.] | ||||

|

| IHC Life Member |

I found some Stay-Brite solder at the local hobby shop. After dispensing a micro-drop of flux on the parts and a tiny sliver of solder, I heated the wheel over my alcohol burner for what seemed to be 5-10 seconds. The solder vanished into the new tooth repair area like magic. The new tooth is just a little wide. When I get some thinner files I will shape it a little better and clean out the radius. It's not a very pretty job but with practice, I hope to improve. I learned a lot just from this first one. John D. Duvall Vice President, Education  | |||

|

| Watch Repair Expert |

Now use an X-acto knife or similar implement to clean the solder off the adjacent teeth, and finish working the new tooth with a small piece of fine sandpaper. That should do the trick. Files thin enough to fit between wheel teeth (even coarse wheel teeth) are hard to find. It's sometimes necessary to grind one side of a thicker file in order to make it thin enough for specialty work. That's also true when a file is needed to make extremely sharp angled notches, etc. ======================= SM | |||

|

| IHC Life Member |

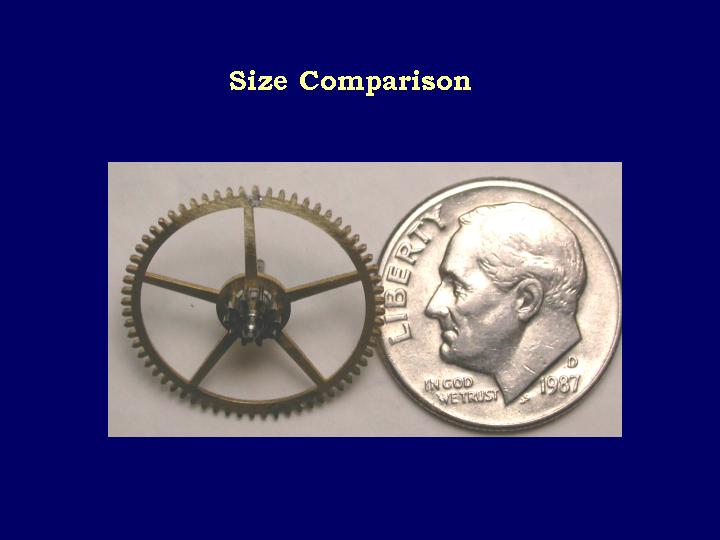

Thanks Steve. I will bond a piece of emery cloth to a thin piece of plastic for rigidity. The comparison of a dime and the center wheel should give everyone an idea of just how small this repair was. John D. Duvall Vice President, Education  | |||

|

| Watch Repair Expert |

John, If you'll use a piece of automotive wet/dry 600 or 1000 grit sandpaper (I prefer Mirka brand, but 3-M is good too), cut to about the size of a postage stamp, there won't be any need for emery cloth or plastic backings, etc. The paper itself will be rigid enough to perform the task quite nicely, and when it becomes dull on the edges (which won't be long when working with solder), you can simply trim it slightly to get to new paper again. Of course, I've been doing that for a number of years, and it's entirely possible there may be a better way. I have the boring habit of sticking with whatever I find that works, and I don't have as much enthusiasm for experimenting with alternative ideas as you seem to have. [-] ================== SM [This message was edited by Lindell V. Riddle on March 29, 2004 at 15:41.] | |||

|

Hi all, I have written my appreciation elesewhere on this site for the help that John and Brian have given me by partnering up to repair my watch. I'd also like to say a big "Thank you" to Steve Maddox for his contributions of advice. Once again, I am impressed by the wealth of knowledge that is shared on this site, and I must thank Steve for his help in getting my watch up and running again. | ||||

|

| Watch Repair Expert |

Glyn, I don't know if I really helped much in this particular instance, but if nothing else, perhaps some of the advice I offered might eventually help someone else. John did a good job, especially for a first attempt, and without having the benefit of any hands-on assistance. From looking at the images of the finished repair, I'm not certain the degree of precision would have been sufficient to work in a later model watch with finer teeth (quick-train), but for the relatively coarse gearing used in the "Home" models, I think it'll be just fine. When reading my various messages here, I hope people will understand that for me personally, it's very frustrating when I spend a portion of my day sharing my years of experience and offering good advice, only to be countered by someone who's never done the particular task at hand before, yet immediately has a better idea. Believe me, I don't know everything, but I do know a little, and to me, it seems it would be better to start by following my advice first, and attempting to improve on it afterwards, rather than assuming one immediately has a better idea. It's fairly obvious that human civilization has advanced to its present state because the written word has allowed people the opportunity to take advantage of the accumulated knowledge of generations past. There's a famous quote by someone who once said something about "standing on the shoulders of giants...." I certainly don't consider myself to be a "giant" by any stretch of imagination, but if I'm nothing more than a doormat, taking advantage of the information I share first, at least offers a minute advantage over starting from the ground. I was in the unfortunate situation of learning the watchmaker's art in the middle of a vast horological desert, and that's one of the main reasons I'm particularly enthusiastic about helping others in that same shape. I began my horological career years before I bought my first computer, and access to the sort of information and advice like that which is offered here, simply wasn't available. The elderly gentleman who helped me initially get started in this profession has my lasting gratitude and appreciation, but my knowledge surpassed his in relatively short time. To continue my own horological education, I started buying books, and I now have a custom-made shelf for them that's 30 inches wide, and 8 feet tall. I don't know how many volumes it contains, but I'd say 400 wouldn't be an unreasonable guess, and I've read them all. While information in books is a tremendous help, it still isn't a substitute for hands-on experience, and I've now had plenty of that as well. I've also encountered instances where conflicting information was provided by different esteemed authors, and I've tried numerous approaches to see which worked better. In this way, I can help people who are trying to learn, and I'm more than happy to, but it's extremely frustrating to try to help people who immediately think they know a better way. In any event, I'm glad your watch is happily ticking again, and I too want to personally commend everyone who helped contribute to that achievement! It's a testament to the sort of things that can be achieved when people are willing to work together. ============== Steve Maddox Past President, NAWCC Chapter #62 North Little Rock, Arkansas | |||

|

Steve, Not a good experience for sure. I have had only one on ebay and it was for less than $40.00. I did get the postal service involved and they sent a threat letter, but I never saw any money. No big deal, live and learn. Jim Hathaway Pasco, WA Jim Hathaway IHC Member #285 | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide