| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Worst Watch "Repairs"

Worst Watch "Repairs"

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Worst Watch "Repairs"

Worst Watch "Repairs"Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| Watch Repair Expert |

OK, I know I'm probably going to hate myself for doing this, but I just can't resist..... What's the worst example of watch "repair" anyone here has ever seen? ============================ Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | ||

|

| IHC Life Member RR Watch Expert |

OK, here goes.... In 1975, as I was just getting started with watches, I bought a Hampden Wm. McKinley at a Mart from a man who assured me that it "had just been completely gone over" by a competent watchmaker. After about four hours in my pocket, the mainspring broke. So, I got my first lession in how to replace a mainspring from a local old time watchmaker who was kind enough to tutor me as I was beginning to learn. I started tracking the timekeeping, and saw that the watch was very erratic, running both slow and fast at different times. After staring at the running movement for a while I saw that one of the escape wheel teeth had been broken off. Whoever had "gone through" the watch had added four pairs of balance screws to slow the watch down enough to keep "approximate" time. Now it was time for lessions on replacing (restaking) a replacement escape wheel onto an arbor and poising and repoising a balance as I kept removing screws to get the watch back into time. Twenty eight years later, I'm still working on watches and I still have the McKinley. Ed Ueberall NAWCC 49688 IHC Member 34 The Escapement | |||

|

That is quite the challenge, I admire your perservence with the watch. I'd love to hear how it comes out one day. Sincerely, David Schweigert | ||||

|

| IHC Life Member RR Watch Expert |

It took me over a week to get the McKinley to keep good time,which it continues to do to this day, since back then I was just starting to do my own work and didn't own a timing machine. At the time I would never have believed that I would someday be doing vintage watch repair and restoration as a full time profession. Ed Ueberall NAWCC 49688 IHC Member 34 The Escapement | |||

|

| Watch Repair Expert |

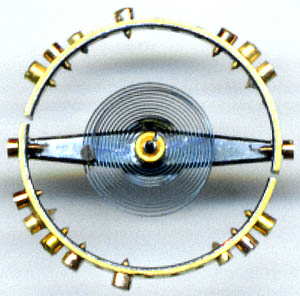

Well, here's one of my all-time favorites... Elinvar hairspring, split compensation balance wheel, and at least 22 timing screws of every size and shape: ===================== Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49  | |||

|

| Watch Repair Expert |

Here's another that I've already posted once this year....... This seventeen-screw "beauty" came out of a customer's 23j Bunn Special. Oddly enough, the complaint was that it didn't time well in positions: ===================== Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49  | |||

|

| Watch Repair Expert |

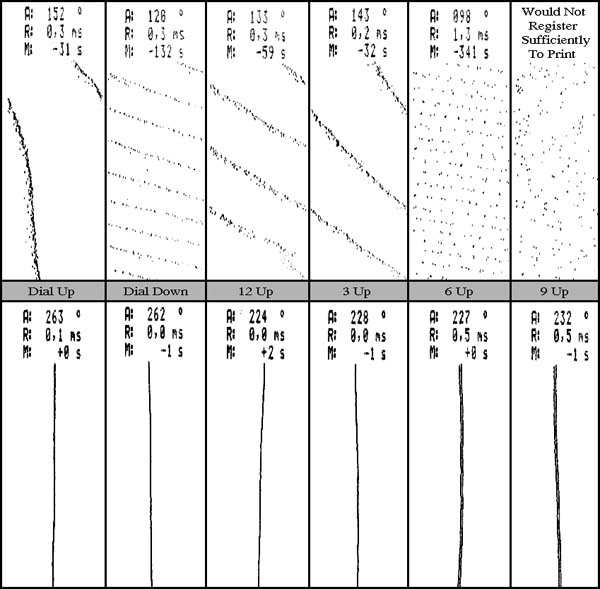

The images below are timing machine recordings (produced by a Vibrograf B-300) from a customer's Rolex that came in for service last year. The graphs at the top show how the watch was running when it arrived; those below show how it ran after I finished with it. Curiously enough, there really wasn't that much wrong with the watch. It had been recently serviced (not by me), and a nice job had been done (clean, well oiled, etc.), but the customer claimed that it wouldn't keep time. Upon inspection, it was found that the most significant problem was that the hairspring overcoil was dragging on bottom of balance cock. Other significant problems were that the escapement was dry, and had a powdery film on faces of pallet stones and escape wheel teeth, and that the balance had vastly excessive endshake, which allowed hairspring to drag worse in the "dial-up" and vertical positions. It's a good example of how a couple of very small problems can keep an otherwise healthy watch from running right. ========================= Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49  | |||

|

| Watch Repair Expert |

Today's entry into the "Watch Repairs NOBODY Wants" category, was encountered in an Elgin ladies pocket watch. The pallet fork and cock are shown in the image below, which is the best I could muster from my flatbed scanner (apologies in advance for the poor image quality). Note that the original burnished pivot jewel has been replaced by a bright red friction jewel, the hole in which measures 0.43 mm, while the pallet pivot measures just 0.22 mm. It is not an exaggeration to say that the jewel hole is large enough to accommodate not only the pivot, but also a large part of its arbor! A correct hole jewel for a pivot of that size would measure 0.23 or 0.24 mm. Next, the outside diameter of the replacement jewel was too large for the existing hole, and if a reamer was used at all, it wasn't nearly adequate for the HUGE replacement jewel. The result was that the metal surrounding the jewel at the end of the pallet cock split all the way through when the jewel was pressed into place. In order to rectify that "small miscalculation," SuperGlue was used to "secure" the jewel into the now ruined pallet cock, and that's what the hazy film is that appears on the right side of the jewel in the image below. It's on both the top and bottom of the jewel and cock, although surprisingly, there wasn't any in the jewel hole (where it might actually have helped fill a part of the excess space!). Needless to say, the watch in which this fine example of craftsmanship was discovered, failed to run, and I can only assume that the watchmaker thus failed to be rewarded for his efforts (at very least, that's what I would hope). Unlike professionals in many other fields, professional horologists typically don't get paid for their services unless they're able to accomplish something beneficial for their customer. We should all hope that creator of the masterpiece below, wherever he is, has found something more productive on which to concentrate his efforts! Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

This site was posted on the "clocks" mailing list and contains some examples of clock and watch repair that would fit this category. Click Here Tom Seymour NAWCC #41293 IHC #104 IHC Exec.V.P. | ||||

|

| Life Achievement Military Expert |

A big 1941 vintage Soviet military wrist watch I bought ran slow and sluggish. Lots of problems. The biggest chuckle was the mainspring which was powering the watch. It had broken in two places but no problem for the Soviet watchmaker who had riveted the three mainspring segments back together with two small rivets and put it back in service! | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide