| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Tick tock

Tick tock

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Tick tock

Tick tockGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Member 2030 |

I have read a lot of posts here, searching for the interesting description of the 5 to 7? Distinct Sounds a mechanical watch makes during a cycle. I saw this somewhere on the net a few months ago, it even had audio. Can anyone help. Thanks Mike | ||

|

hi Mike, i think this is what you are asking about. the part you are talking about starts near the middle. https://www.youtube.com/watch?v=g5c5RK4WFV8 i spend a lot of time researching watch info on the net. if you find something else let me know please. very interested. Todd | ||||

|

| IHC Member 2030 |

Yes that may be the one. Thanks The sophisticated computer graphics make the machine awesome. Pretty clean movement, no dirt! | |||

|

| IHC Member 2030 |

| |||

|

| IHC Life Member |

THIS IS A VERY GOOD VIDEO. THANKS. | |||

|

| IHC Life Member |

Beautiful audio and graphics. You might notice that this also exhibits the nature of escapement regulated clocks and watches which is a nightmare for Tribologists (Lubrication scientists)! Why? The wheel train of a typical 18,000 BPI pocket watch (for example) remains stationary 99% of the time, having to come to a full stop and then has to start moving again 18,000 times an hour. Each "Tick" or "Tock" is a millisecond start-stop event which requires microscopic rotation of an ever less torqued wheel train. This is the antithesis of the "Stick-Slip" issue with all linear and rotating bearing systems. Think of it another way, I remember a short moment's morning prayer at -20 Deg. F in the middle of my Minnesota winter before I pushed the 6 volt starter button on my 1950 Ford. Getting all that machinery going (slipping) from an at rest (stuck) position was a real chore. Especially for those wimpy 6 volt starters which would rather catch fire and self destruct than be stuck for more than a fraction lf a second. Anyway, the fact that our watch wheel train is NOT moving AT ALL for over 99% of the time is a sobering reminder why we willingly pay $40.00 for a 20Ml (some drops) bottle of watch oil. | |||

|

| IHC Member 2030 |

Agreed, the visuals of machines are critical for maintains them. There are movable span railway bridges that are 120+ years old, still operating with diligent lubrication. Watches are the much smaller relatives, it is a great journey to aspire to be a maintainer. The computer graphic 'movies' of these machines above are tribute to the people who built them without computers, or even electricity ... I hope my gears are moving 100% of the time although some quite slowly. 1.0rpm,1/60rpm,1/3600rpm, etc. Mike | |||

|

Great video fellas, my mechanical aptitude is somewhat challenged at times. The escapement segment particularly enlightening. Many thanks for sharing. Rick | ||||

|

| IHC Member 2030 |

Oops, upon further mental review, the movement of the gear train is not continuous or 100% as I stated above. Sorry for the error. It does stop periodically of course (approximately 6 times per second?) while the escapement stops. These brief hesitations add up to 99% stopped? There should be an equation for percent time stopped and therefore percent time moving. The journey continues. | |||

|

| IHC Life Member |

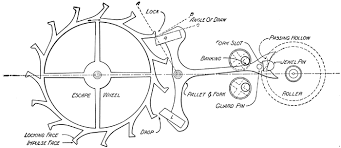

The free swing arc of the balance wheel is (should be) 270 degrees of arc each way during the Tic-Toc cycle. As shown by the sketch below, at the return of each 270 degree cycle of the balance wheel (right side) the roller jewel intersects and pushes the pallet fork which rotates slightly and unlocks the pallet jewel allowing the slight interference torque of the escape wheel heel on that fork jewel to kick the fork against the roller jewel for an instant propelling the jewel against the other tine of the fork and locking the opposite pallet jewel into the next tooth of the escape wheel stopping the movement again. This "event" happens in less than 2 degrees of wheel rotation. As the 270 degrees of wheel rotation happens 5 times a second, a period of 200 milliseconds, each degree of wheel rotation in that period is <1 Millisecond. Hence the propulsion time and movement rotation time is less than 2 milliseconds for every 200 milliseconds of time. So I was wrong, in general the actual percentage to true time the watch movement parts are moving is 0.5-1.0% of real time and the watch is at "rest" 99.0-99.5% of the time.  | |||

|

| IHC Member 2030 |

Thank you David, the logic is sound and I concur. Sincere apologies for being impertinent and dragging this out, but this visualization is important to me. Please help finding the flaws in this logic and math: I see 270 degrees movement of the balance wheel resulting in a 24 degee 'allowed' free movement of the escape wheel. As a direct ratio, the pallet fork is in motion for 11.25 degeees of the 270 (270/24= 11.25). Therefore, the fork is moving 4.16% of the period and 'waiting' for the pallet jewel 95.84% of the period (11.25/270 = 0.0416 or 4.16%). There are probably some losses unaccounted for above. I appreciate any thoughts or criticism. I can let this go and now tell people my 'running' watches are 99% dead and the non-runners are only 1% from being alive. Mike | |||

|

I just watched the video on how a pocket watch works. It was fascinating and informative. Thanks for putting it in this forum Michael C. Bussacco | ||||

|

| IHC Member 2030 |

More research for those who like to get in the weeds of watch mechanics. Near the end,page 81, double roller escapements are described. http://www.abbeyclock.com/escudo.html Mike | |||

|

| IHC Member 2030 |

This is PDFs http://www.abbeyclock.com/EscMechanics.pdf | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide