| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Jeweling an ELGIN plate jewe

Jeweling an ELGIN plate jewe

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Jeweling an ELGIN plate jewe

Jeweling an ELGIN plate jeweGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

Hi Group, Don't know if I am brave or stupid. The latter I think! I have an 18s Elgin , S/N 2005988. Grade 13 Class 5 Circa 1887 that needs an escape wheel plate jewel. Cracked. The wheel pivot measures 23 1/2 mm, and the od in the plate looks like 1.50 mm. I have lots of jewels, but not sure what the exact profile looks like. Going for 24x150. I think I can get the old one out with a punch from the other side and clean it up and measure the counterbore to determine the correct OD. Are they just pressed in with NO "BURNiSHING IN" over the top to retain it in place? Help in my case is always welcomed. PS Any suggestions as to reassembling the jewel as well as reassembling the final parts. The yoke passes thru a high hat in the top plate. Was thinking it might be easier to re-assemble on the top plate, then add base plate, them mainspring barrel, then dial and hands. Thanks in Advance Mel | |||

|

| IHC Member 1736 |

Melvin, I'd love to see some pictures of the process and tools involved as the project progresses. This is one area I have had zero success... and don't even attempt anymore. Screw set jewels are easy money... pressed jewels are a write off for me. Paul | |||

|

| IHC Life Member |

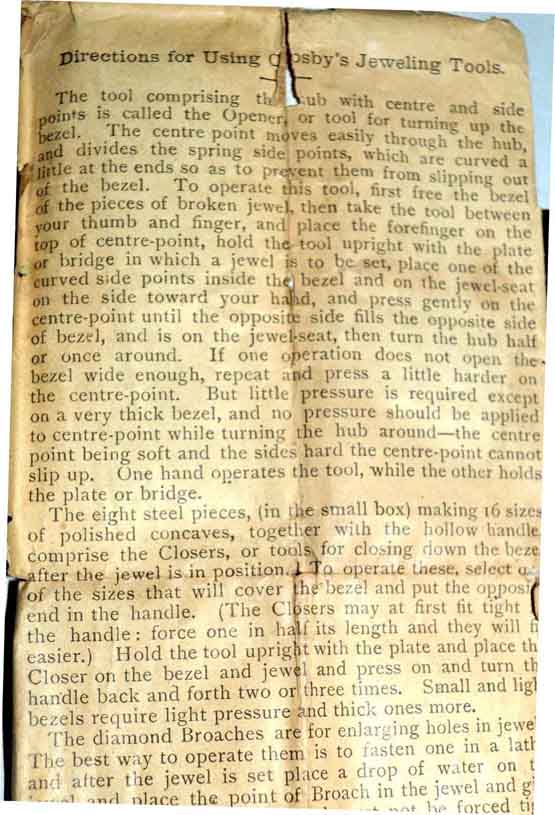

The Chicago school of watchmaking book pretty well explains this process. The following describes dealing with the flat friction jewels you are talking about; | |||

|

| IHC Life Member |

The tools described in these instructions are included with most good staking sets. Picking the repacement jewel is the issue. | |||

|

| IHC Life Member |

This a fairly easy fix if you have the right tools and the correct jewel. The info that dave gave is the easiest way to to do it. | |||

|

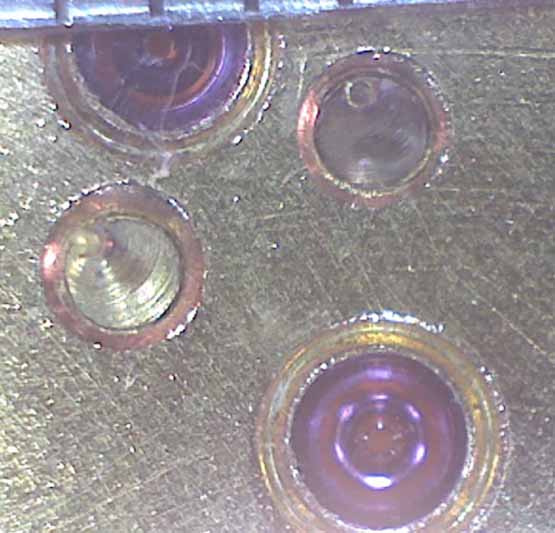

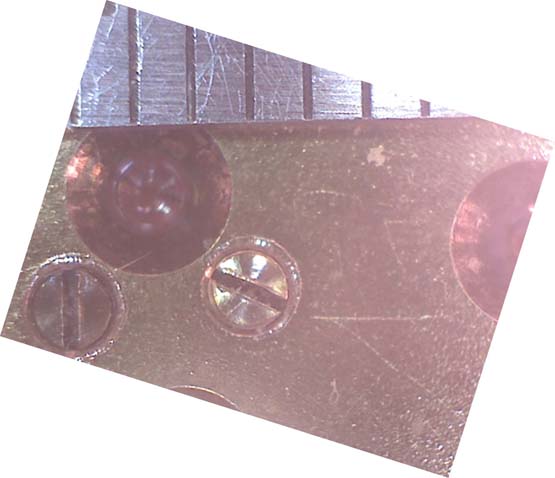

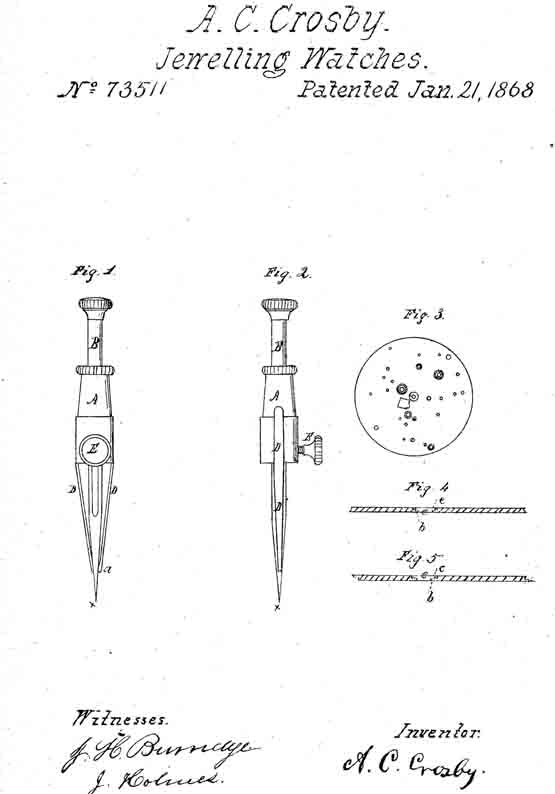

Hi Guy, And thanks so far. I am still gathering my courage, ugh... I have taken a series of pictures and hope they come thru. The one of the cracked escape jewel is taken from two sides, the movement side and the opposite side, both with a ruler for scale. (I call it the top). The movement side shows the outer diameter of the jewel about 150 mm +/-. But it looks to me like it is rolled over to retain the jewel from the movement side. The outer side shows a counter-sunk hole approx 100 mm. (Not important except for pushing out the old jewel). I think that the movement side is countered bored, to some depth to allow the jewel to "bottom" out, and be square to the plate top. Thus the thickness is important. Then it looks like material was rolled over, to retain it. (?). Some time ago I purchased a "CROSBY JEWELING TOOL", patent applied for sometime in the late 1800's. The way it is supposed to work, I think is... After the broken jewel is removed, the first operation is to "recondition" the counter-bored hole. Then press in a jewel of proper size. Pictures to follow. Boy I am glad this is not my real job, this cannot be worth the effort if I had to pay for it. Thats why they call it hobby. | ||||

|

Cracked Jewel Mvmt side  | ||||

|

Cracked jewel outer side  | ||||

|

Crosby patent Jeweling kit  | ||||

|

Instreuctins  | ||||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide