| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  No Endshake and Cracked Jewels on Elgin 0 Size

No Endshake and Cracked Jewels on Elgin 0 Size

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  No Endshake and Cracked Jewels on Elgin 0 Size

No Endshake and Cracked Jewels on Elgin 0 SizeGo  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member Site Moderator |

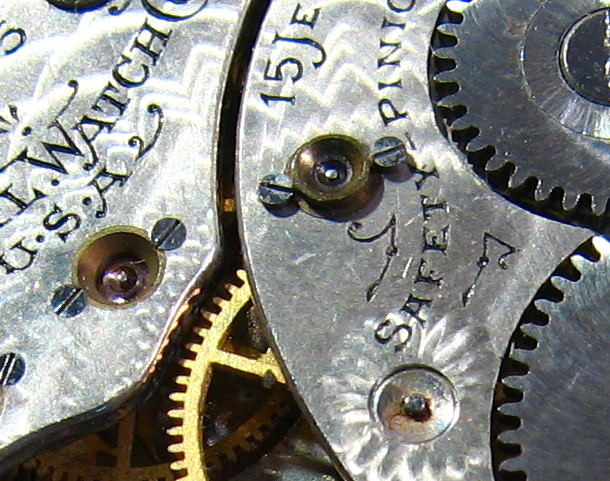

I'm trying to reassemble a solid gold 0 size Elgin 15 jewel pocket watch. The watch was not running when I took it apart and cleaned it. I found that the third wheel upper and lower jewels were cracked, but the jewels were still relatively intact so on the advice of Mr. Abbe, I decided to leave them as is. Unfortunately, when I replaced the barrel bridge, the third wheel became very tight. Essentially, there is no endshake on this wheel. It is so tight that the center wheel also will not turn when the plate screws are tightened. The center wheel is not jeweled, but turns fine by itself and has adequate endshake. Now I think I know why it wasn't running and why the jewels were cracked: too much friction in the third wheel. I loosened the third wheel upper jewel screws a bit and it freed up somewhat, but it worries me why this wheel is so tight. I should be able to tighten down the jewel screws and have the wheel turn without any friction. Also, the jewel setting looks much different than the 4th and escape wheels. I'm suspicious that this was an attempted repair that didn't work, probably a long time ago. I've included a picture so you can see what I'm talking about. The 3rd wheel is the one in the middle of the picture, center wheel is a the bottom, 4th wheel on left. Any ideas on what to do next? Is there a way to shorten the pivots so that the wheel fits better between the plates? Thanks, John III  | ||

|

| IHC Life Member Watchmaker |

There are a couple of ways to go here. One, you can change the jewel, you could even put a friction jewel in it (Although this would be easy, it would also look a bit out of place.) You can chuck the wheel up on a lathe and reduce the size of the pivot, or the shoulder, or both. You might check to see if it is the correct wheel for the watch. | |||

|

| IHC Life Member Site Moderator |

Thanks Scott. I appreciate the info. I'll let you know works out. | |||

|

| IHC Member 376 Watchmaker |

John i have a 15 jewel that has the same jewel setting as your movement has on the 3rd wheel it rund fine and i belive it ,s right. the 4rd and escape wheel jewels are the same as yours. ,,my guess would be the 3rd wheel has been changed. | |||

|

| IHC Life Member Site Moderator |

Update: This weekend, I changed out the third wheel with one from a parts movement I had and everything is working fine now. Thansk for the advice everyone. John | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  No Endshake and Cracked Jewels on Elgin 0 Size

No Endshake and Cracked Jewels on Elgin 0 Size

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  No Endshake and Cracked Jewels on Elgin 0 Size

No Endshake and Cracked Jewels on Elgin 0 Size©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide