| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Video on staff replacement (Important Recommendations Made)

Video on staff replacement (Important Recommendations Made)

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Video on staff replacement (Important Recommendations Made)

Video on staff replacement (Important Recommendations Made)Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

https://www.youtube.com/watch?v=jiXAFKati1c. Very clear video on staff repair for those using a K & D 50. https://www.youtube.com/watch?v=hk4ULBfWpzk for friction staff. You Tube has a lot of watch repair videos. | ||

|

hi Patrick, yes there are a lot of vids on watch repair, but some of the things i have seen are so bad even i know they are wrong. Todd dalarry | ||||

|

| IHC Life Member |

Good show. Patrick. While the use of the #50 staff remover has it's adherents and detractors, the video illustrates accurately how that is done. | |||

|

Hi Patrick, I've watched most of this guy's videos and they're usually quite entertaining. He seems to be completely self taught and some of the thing he's does are very wrong so you need to be careful and not take all he says as gospel. Still a very good watch and the best of luck to someone who's at least having a go. He has pocket watches at heart. Mike | ||||

|

| IHC Life Member |

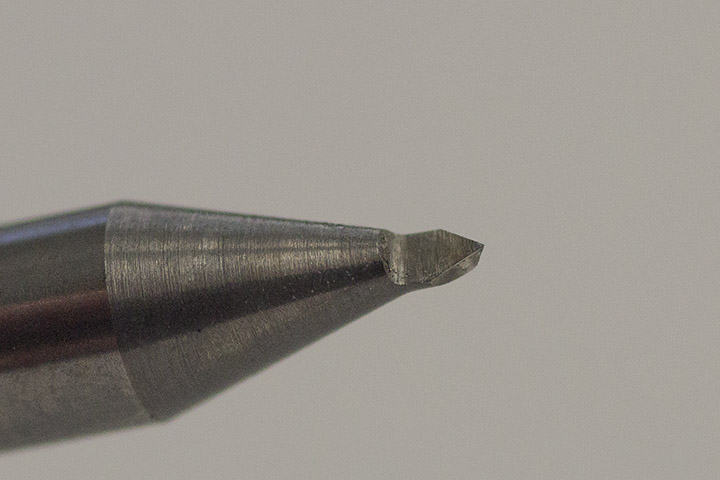

Patrick, There was a big discussion about the proper way of removing riveted staffs HERE. Personally, I used a very sharp carbide graver to cut the rivet away, making it possible to simply push the staff out without the use of a hammer. While the nifty K&D attachment provides a quick method of removing the staff, it does so through the use of force. Adjusted grade watches, in my opinion, deserve much more care than that. Here's and image of a tiny graver that I made just for this purpose, from an inexpensive miniature carbide drill bit. Worked perfect every time! :0) William  | |||

|

| IHC Life Member |

2  | |||

|

| IHC Life Member |

William, yes I remember the discussion and the picture of your tools (very neat idea) I think that was about three months ago or so. I am one of the diehards that still cut or grind the staffs out. I remember David sticking by the K & D 50 tool and that is fine. To each his own. I just ran across this video on using the punch tool KD 50 and though someone could use it. You can never hurt anyone by education. | |||

|

Can anyone post a picture of the K & D 50. Thanks, Mike Thanks for posting Patrick. That's identified another mystery tool which lives in my staking set. | ||||

|

| IHC Life Member |

K&D 50 | |||

|

| IHC Life Member |

Patrick, The K&D #50 was a very popular accessory. It was introduced at a time when watchmakers were very busy, every working day of every week. This little tool provided a quick and easy way of removing a balance staff and due to its fair design, it did so with minimal damage in most cases. We can't argue with the need to maximize the profitability of a workday in an era when most mechanical watches were not seen as valuable artifacts but instead, common mechanisms which needed to be serviced, in numbers greater than any other machine of that time, even car engines! Today is different and the great majority of watch repair people we know are not engaged in this craft as a sole source of income and the few that are don't need to shave 5 minutes off of every staff job, as was the case yesteryear. Instead, we are now conservators. We have the luxury of choosing the more precise art of simple & fine lathe work over a handy-dandy time saving tool ...AKA the K&D #50. Just my opinion! William | |||

|

| IHC Life Member |

Thank you William for your absolutely superb post. I have stated time and again the K&D 50 and any other tool like it should NOT be used today. I'll say this again too...just because someone makes a tool to do a job, that doesn't mean it is a good tool or the best way to do a job. These tools absolutely will distort the balance arm hole and the more times used on the same balance the more damage is done. I stand with you on the opinion that this tool should never be used today. | |||

|

| IHC Life Member |

William & roger, I wholly respect your opinion and agree. | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Video on staff replacement (Important Recommendations Made)

Video on staff replacement (Important Recommendations Made)

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Video on staff replacement (Important Recommendations Made)

Video on staff replacement (Important Recommendations Made)©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide