| WWT Shows | CLICK TO: Join and Support Internet Horology Club 185™ | IHC185™ Forums |

|

• Check Out Our... • • TWO Book Offer! • |

Welcome Aboard IHC185™  Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Watch Trivia Question #1

Watch Trivia Question #1

Internet Horology Club 185

Internet Horology Club 185  IHC185™ Discussion Site Main Page

IHC185™ Discussion Site Main Page  Technical, Shop Talk and Internet Links

Technical, Shop Talk and Internet Links  Watch Repair Questions and Answers

Watch Repair Questions and Answers  Watch Trivia Question #1

Watch Trivia Question #1Go  | New Topic  | Find-Or-Search  | Notify  | Tools  | Reply to Post  |  |

| IHC Life Member |

The "Safety Pinion" utilized on American watches screws onto the center wheel arbor using what type of threading? (Please, no peaking until you choose one) John D. Duvall Vice President, Education [This message was edited by John D. Duvall on October 30, 2003 at 7:08.] | ||

|

Umm, whats a Safety Pinion? Mike Nardick NAWCC # 144409 IHC Charter Member 26 Member Allegheny Chapter 37 mikena32@comcast.net | ||||

|

| IHC Life Member |

Mike, Here is your answer sir! John D. Duvall Vice President, Education [This message was edited by John D. Duvall on October 25, 2003 at 16:03.] | |||

|

Thank you sir Mike Nardick NAWCC # 144409 IHC Charter Member 26 Member Allegheny Chapter 37 mikena32@comcast.net | ||||

|

| IHC Member 155 Bulova Watchmaker |

John, Good educational question I will be following the reults. I did vote. Rich Kuhn NAWCC 128623 IHC Member 155 eMail: rich@watchmakerfinds.com Web-Site: http://watchmakerfinds.com eBay Auctions: watchmakerfinds eBay Auctions | |||

|

| Watch Repair Expert |

You have to admit, those answers are interesting! ==================== Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

John D. Do the waltham safety unscrew in the same direction?  | ||||

|

| IHC Life Member |

Wayne, I'm going to wait with the answers until this coming weekend. I want to give everyone a chance to guess. John D. Duvall Vice President, Education | |||

|

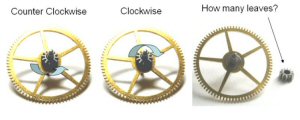

John D. Its fall in New England - and was wondering how many leaves there are?  | ||||

|

| IHC Life Member |

Poll results: Left Hand Thread: 57% Right Hand Thread: 13% Both Type Threads: 30% Wayne has posted the correct answer. His picture depicts that both Left and Right Hand threads were used. Also, someone needs to answer Wayne's question on the number of "leaves." My guess is more than eleven but less than thirteen. I first noticed the use of Right hand threads while working on an Elgin 6s movement. Thanks to all that participated! John D. Duvall Vice President, Education | |||

|

| Watch Repair Expert |

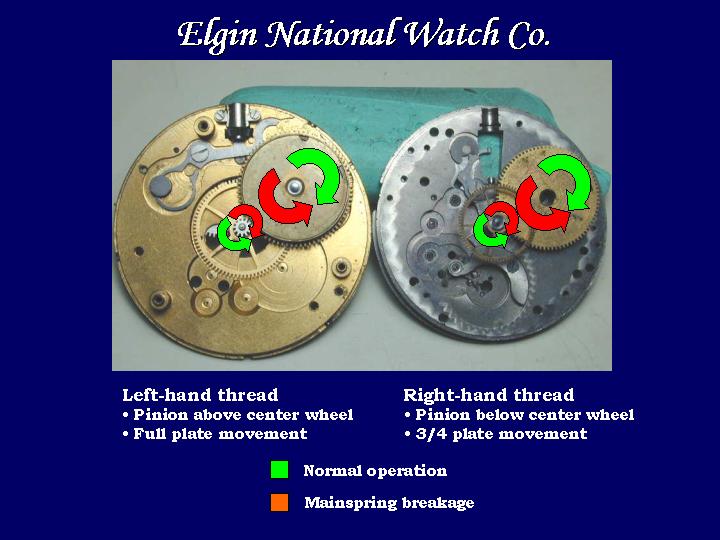

The key is understanding that the pinion must ALWAYS tighten onto the wheel hub in the ordinary running direction, regardless of whether the hub is above or below the pinion. For watches with the pinion above the wheel, the pinion will need to tighten in opposite direction from watches with the pinion below the wheel. Typically (although not always), that difference is found between "full-plate" movements, and "3/4 plate" models. Perhaps the sketch below will help make things more clear....... ========================== Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

| IHC Life Member |

Here is a slide to go with Steve's excellent dissertation. Hope the directions are correct! The movement on the left is a full plate Elgin 18s and the movement on the right is a 3/4 plate Elgin 16s. If the mainspring should break, the frictional force of the broken spring whipping around inside the barrel will cause the barrel to turn in the wrong direction. This will cause the Safety Pinion to unscrew and prevent this violent force from damaging the train components. John D. Duvall Vice President, Education  | |||

|

| Watch Repair Expert |

I was looking for a way to do something like that, but I couldn't decide how to go about it, and finally I just gave up and didn't even attempt it. In any event, as can be plainly seen in John's illustrations, the usual running directions are the same for both full and 3/4 plate models (obviously, since both turn the hands clockwise). What's different is the location of the safety pinion relative the center wheel. The key is that although the turning directions are the same, if the wheel is ABOVE the pinion, the thread direction must cause the center pinion to "rise" in the running direction, so as to tighten "up" against the center wheel. Alternatively, if the center wheel is BELOW the pinion, the pinion must tighten "down" against the center wheel. Obviously, in order to make a pinion go "up" when turned in a particular direction, or go "down" when turned in that SAME direction, the pitch of the threads must be reversed. John and I understand this topic, as did 30% of the participants to start with, but just out of curiosity, has ANYONE found the explanations above understandable and/or informative? Oh, one other point I'd like to attempt to clarify: The reason a "safety pinion" is necessary, is essentially as John described above, with one small difference. It isn't "the frictional force of the broken spring whipping around inside the barrel" that causes damage in the event of spring failure, it's the sudden stop when the body of the spring fills the barrel and doesn't have any additional room for expansion. Think of it like an old fashioned screen door spring. When the spring is stretched out, it has a lot of kinetic energy stored in it. If all of a sudden, one end of that spring is released, the body of the spring is going to fly forward like a hammer, and it's going to have considerable momentum by the time all the slack is taken up. At that point, something will have to absorb all the kinetic energy that was suddenly released and converted into momentum. For all practical purposes, the mainspring in a watch acts exactly like a long coil spring. In the event that one end breaks, as soon as all the slack has taken up, there's going to be a very sudden jolt at the other end. ============================ SM | |||

|

| IHC Member 234 |

...am happy to be counted among the 30 percenters but admittedly for reasons that I also managed to pass many 'multiple choice' exams at school by choosing the 'Both A and B' option in response to the question posed... | |||

|

| IHC Life Member RR Watch Expert |

Just to add a little to the excellent discussion above. A watch containing a "motor barrel", that is, a barrel where the spring is wound by rotating the outer barrel and unwound (powering the watch) by rotating the center arbor, does not require a safety pinion. This is one reason why Waltham, (Keystone) Howard and others referred to them as "safety barrels". If a spring in such a system breaks, the force released will cause the outer barrel to rotate rapidly (or try to). Since the gear train is only connected to the arbor, the barrel force will just spin the winding clutch backwards, causing no damage. Now, have I completely confused everyone? Ed Ueberall NAWCC 49688 IHC Member 34 The Escapement | |||

|

As Jim, I also make the correct selection not really knowing, just assumed that there are so many different models that both posibilites could exist. Thanks John, Steve, Wayne and Ed for putting the matter in black and white, or rather in full color.... this board is so d... good! | ||||

|

| Watch Repair Expert |

A fellow on another message board reported finding a Ball-Hamilton with a motor barrel, as well as a safety pinion, and inquired as to why a watch would have both. The following is a copy of my rather lengthy answer: --------------------------------- "In order to really understand the problem that arises when a mainspring breaks, it's better to think of the spring as a long coil spring (like a screen door spring), rather than the spiral spring that's actually used. With any type of spring, the force at one end is equal to the force at the other end. In other words, if you stretched out a screen door spring between your two hands, each hand would be pulling an exactly equal amount of force. That means that regardless of which end of the spring is 'fixed,' and which is 'movable,' each end has exactly the same tension. Now, with the door spring stretched between your hands, imagine what would happen if it were to suddenly break (particularly near one end). All the tension would be instantly released, and the two resulting sections of spring would generate considerable momentum as they snapped back into their relaxed state. Obviously, the largest portion would develop the most momentum, and as soon as the 'slack' was absorbed, the spring would act like a hammer. When a watch mainspring breaks, exactly the same thing happens. Of course, it's possible for a spring to break at any point, but the most common failure sites are near the ends. In a watch with a standard 'going barrel,' if the spring breaks near the barrel hook (outer end), it's not likely that any harm will result to the movement. Several coils of the spring will rapidly unwind inside the barrel, but the attached end remains anchored to the barrel arbor, and once the spring starts to unwind, the loose (outer) end will begin expanding in the barrel and acting like a 'brake' to slow the rate of release by relatively gradual degrees. On the other hand, when the mainspring breaks near barrel arbor (inner end), the entire length of the spring is free to develop a huge amount of momentum as it rapidly unwinds to fill the barrel. Since the only thing that's holding the barrel is the engagement of its teeth with the center wheel, at the instant when the spring reaches the end of it's available expansion room, all the momentum it's developed is going to be transferred to the barrel teeth, center pinion, etc., and it's very likely that the resulting jolt will be more than some of those parts can withstand. In watches equipped with a 'safety barrel,' the outside of the barrel is actually attached to the barrel arbor (via a square or 'D-shaped' hole in the barrel and a matching shoulder on the arbor). When a mainspring breaks and the broken end develops momentum as it unwinds, the force once it reaches the end is transmitted through the barrel arbor, and the ratchet wheel is free to rotate until the force is harmlessly expended. The 'arbor hook' is ultimately attached to the 'great wheel,' which is what drives the center wheel. The 'barrel hook' is ultimately attached to the ratchet wheel, instead of the center wheel, as it would be in a conventional 'going barrel.' With the 'motor barrel' such as employed in Hamilton and Illinois products (as well as a few others), the outer end of the mainspring is attached to the outside of the barrel, which has the wheel teeth on it, exactly like an ordinary 'going barrel.' With this arrangement, the advantage gained by the 'safety barrel' system is lost, and a broken mainspring would still result in the same shock to the gear train as in a watch equipped with a 'going barrel.' In short, a 'motor barrel' is NOT equivalent to a 'safety barrel,' and the terms shouldn't be used interchangeably. With 'safety barrels,' such as are commonly found in many Waltham and Elgin models, a safety pinion on the center wheel isn't necessary. Watches equipped with only a 'motor barrel,' however, have no more 'safety' factor than a watch with an ordinary 'going barrel,' and they still require the use of a 'safety pinion.' In the accompanying sketch, figure 'A' depicts a cutaway view of a standard 'going barrel.' Figure 'B' depicts a similar view of a 'motor barrel' (such as was used by Hamilton, Illinois, etc.), and figure 'C' a view of a 'safety barrel,' as was used by Waltham (Elgin used a different, but similar arrangement). In all of the figures, winding is accomplished by the blue parts (the ratchet wheel is at the top of each figure), and power to the train is applied through the yellow parts (the 'great wheel'). A cutaway view of the mainspring is represented by the purple bars. Note that in figures 'A' and 'B,' power is supplied to the train by the outer end of the mainspring, and winding is accomplished through the inner end. In figure 'C,' however, power is supplied to the train by the INNER end of the mainspring, and winding is accomplished by the outer. This makes all the difference in whether or not a safety pinion is needed in the event of mainspring failure." As always, I hope this helps! ===================================== Steve Maddox President, NAWCC Chapter #62 North Little Rock, Arkansas IHC Charter Member 49 | |||

|

| Powered by Social Strata |

| Your request is being processed... |

|

©2002-2025 Internet Horology Club 185™ - Lindell V. Riddle President - All Rights Reserved Worldwide